3970875

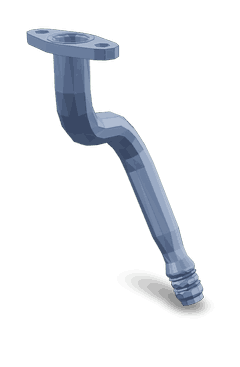

Turbocharger Oil Drain Connection

Cummins®

IN STOCK

1 is currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbocharger Oil Drain Connection (Part #3970875) by Cummins is a component designed to facilitate the drainage of oil from the turbocharger in heavy-duty truck engines. Its purpose is to ensure that the turbocharger operates efficiently by maintaining clean oil levels, which is significant for the overall health and performance of the engine 1.

Basic Concepts of Turbocharger Oil Drain Connection

Turbocharger oil drain connections operate on the principle of allowing used or contaminated oil to be expelled from the turbocharger system. This process is vital for maintaining the turbocharger’s internal components, such as bearings and seals, in optimal condition. By regularly draining old oil, the system prevents the buildup of contaminants that could lead to decreased performance or damage 2.

Role and Function in Truck Operation

The Turbocharger Oil Drain Connection plays a role in the operation of a truck by contributing to the efficient functioning of the turbocharger. It ensures that the turbocharger receives clean oil, which is crucial for lubrication and cooling of its moving parts. This, in turn, helps in maintaining engine performance and efficiency, allowing the truck to operate smoothly under various conditions 3.

Key Features

The Cummins Turbocharger Oil Drain Connection is characterized by its robust design and high-quality materials, which enhance its performance and durability. It is engineered to withstand the high pressures and temperatures associated with turbocharger operations. Additionally, its design ensures a secure connection, minimizing the risk of leaks and ensuring that the oil drainage process is efficient and reliable.

Benefits

Using the Cummins Turbocharger Oil Drain Connection offers several benefits. It contributes to improved turbocharger longevity by ensuring that the turbocharger is always lubricated with clean oil. This results in enhanced engine performance, as the turbocharger can operate more efficiently. Additionally, the use of this component can lead to reduced maintenance requirements, as it helps prevent issues related to oil contamination 4.

Installation and Compatibility

Proper installation of the Turbocharger Oil Drain Connection is important to ensure its effective operation. It is designed to be compatible with various Cummins turbocharger models and heavy-duty truck engines, making it a versatile component for fleet managers and maintenance professionals. Following the manufacturer’s guidelines for installation ensures that the component functions as intended within the turbocharger system 5.

Maintenance and Troubleshooting

To ensure optimal performance of the Turbocharger Oil Drain Connection, regular maintenance is recommended. This includes inspecting the connection for signs of wear or damage, cleaning it as necessary, and ensuring that it remains securely attached. Troubleshooting common issues, such as leaks or inefficient oil drainage, can often be addressed by checking the connection’s integrity and ensuring that all components are properly aligned and tightened.

Common Issues and Solutions

Common problems that may arise with the Turbocharger Oil Drain Connection include leaks, blockages, or inefficient oil drainage. These issues can often be resolved by inspecting the connection for damage, cleaning any debris that may be obstructing the flow, and ensuring that all components are correctly installed. Preventive measures, such as regular maintenance checks, can help avoid these issues and ensure the turbocharger system operates efficiently.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the automotive and heavy-duty truck industries, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s product offerings are designed to meet the demanding requirements of various applications, ensuring reliable performance and efficiency.

Turbocharger Oil Drain Connection (Part 3970875) in Cummins Engines

The Turbocharger Oil Drain Connection (part number 3970875) is a critical component in the lubrication system of certain Cummins engines. This part is designed to facilitate the drainage of oil from the turbocharger, ensuring that the turbocharger operates efficiently and reliably.

ISB (Chrysler) Engines

In the ISB engines, the Turbocharger Oil Drain Connection is integral to maintaining the turbocharger’s lubrication. The ISB series, known for its robust performance, relies on this part to prevent oil from accumulating in the turbocharger, which could lead to overheating and potential damage.

ISB CM850 Engines

Similarly, in the ISB CM850 engines, the Turbocharger Oil Drain Connection (part 3970875) plays a vital role. The CM850 variant is designed for high-performance applications, and the efficient drainage of oil from the turbocharger is essential to maintain optimal operating conditions. This part ensures that the turbocharger receives the correct amount of lubrication, contributing to the engine’s overall longevity and efficiency.

Grouping of Engines

Both the ISB and ISB CM850 engines share a common design philosophy that emphasizes durability and performance. The Turbocharger Oil Drain Connection is a shared component in these engines, highlighting its importance across different variants. This commonality underscores the significance of maintaining this part to ensure the engines’ reliability and efficiency.

Role of Part 3970875 Turbocharger Oil Drain Connection in Engine Systems

The Turbocharger Oil Drain Connection (Part 3970875) is an essential component in the maintenance and operation of turbocharger systems within engine assemblies. This part is specifically designed to facilitate the drainage of oil from the turbocharger, ensuring that the lubrication system remains efficient and that the turbocharger operates within optimal parameters.

Integration with Turbocharger Plumbing

In the context of turbocharger plumbing, the Turbocharger Oil Drain Connection serves as a vital junction point. It is strategically positioned to allow for the periodic removal of oil that has circulated through the turbocharger’s bearings and other moving parts. This drainage is necessary to prevent the accumulation of contaminants and degradation products that can form in the oil over time, which could otherwise lead to reduced efficiency and potential damage to the turbocharger.

Function within the Turbocharger System

Within the turbocharger itself, the oil drain connection is part of a closed-loop lubrication system. The turbocharger relies on a steady supply of clean oil to lubricate its rotating components, such as the turbine and compressor wheels, as well as the bearings. The Turbocharger Oil Drain Connection allows for the extraction of used oil, which can then be replaced with fresh oil, maintaining the integrity of the lubrication system.

Interaction with Engine Plumbing

The plumbing of the engine, which includes all the hoses, pipes, and connections that transport fluids throughout the engine system, must be carefully designed to accommodate the Turbocharger Oil Drain Connection. This ensures that the oil can be efficiently drained from the turbocharger without interfering with other engine operations. The connection point must be easily accessible for maintenance purposes, allowing mechanics to perform oil changes and inspections with minimal disruption to the engine’s operation.

Maintenance and Operational Efficiency

Regular maintenance of the Turbocharger Oil Drain Connection is important for the overall efficiency of the engine. By ensuring that the oil drain system is functioning correctly, engineers and mechanics can help to prolong the life of the turbocharger and enhance the performance of the engine. This component plays a significant role in the preventative maintenance strategy for turbocharged engines, contributing to their reliability and durability.

Conclusion

The Turbocharger Oil Drain Connection (Part #3970875) by Cummins is a vital component in the maintenance and operation of turbocharger systems within heavy-duty truck engines. Its role in facilitating the drainage of oil ensures that the turbocharger operates efficiently, contributing to the overall performance and longevity of the engine. Regular maintenance and proper installation of this part are essential for optimal engine operation and efficiency.

-

Smil, V. (2010). The History and Impact of Diesel Engines and Gas Turbines. The MIT Press.

↩ -

Fijalkowski, B.T. (2011). Automotive Mechatronics Operational and Practical Issues Volume 1. Springer.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5504561.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5504561.

↩

SPECIFICATIONS

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| O Ring Seal | 2 | 3928624 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.