This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

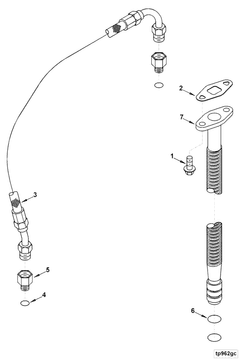

The Turbocharger Oil Drain Connection, identified by Part #3977615, is a component manufactured by Cummins, a well-established name in the automotive industry. This Cummins part is integral to the operation of heavy-duty truck engines, facilitating the efficient management of oil within the turbocharger system. Its role is significant in maintaining the turbocharger’s efficiency and longevity, contributing to the overall performance of the engine.

Basic Concepts of Turbocharger Oil Drain Connection

Turbocharger oil drain connections serve a fundamental purpose within the turbocharger system. They are designed to manage the flow of oil, ensuring that it is efficiently drained from the turbocharger. Proper oil management is vital for maintaining the turbocharger’s efficiency and extending its operational life. The oil drain connection plays a role in this process by providing a pathway for oil to be removed from the turbocharger, preventing oil buildup and contamination that could otherwise impair performance 1.

Purpose and Role in Truck Operation

The Turbocharger Oil Drain Connection part 3977615 is specifically designed to enhance the operation of heavy-duty truck engines. It contributes to the turbocharger’s performance by ensuring that oil is effectively drained, which helps in maintaining the turbocharger’s efficiency and reliability. This, in turn, supports the engine’s overall performance, allowing it to operate more smoothly and efficiently. The proper functioning of the oil drain connection is therefore integral to the sustained reliability and performance of the turbocharger and, by extension, the engine 2.

Key Features

The Turbocharger Oil Drain Connection part 3977615 is characterized by several key features that enhance its functionality and durability. Its design incorporates elements that ensure efficient oil drainage, while the materials used in its construction are selected for their durability and resistance to the harsh conditions within a turbocharger system. Unique characteristics of this part may include precision engineering for a secure fit and operation under high pressure, as well as compatibility with specific turbocharger models to ensure optimal performance 3.

Benefits

The advantages offered by the Turbocharger Oil Drain Connection part 3977615 include improved oil drainage efficiency, which helps in reducing the risk of oil contamination within the turbocharger. This leads to enhanced turbocharger performance and longevity, as the turbocharger operates more efficiently and with less wear. The part’s design and materials contribute to its durability, ensuring that it can withstand the demanding conditions of heavy-duty truck engines 4.

Troubleshooting and Maintenance Suggestions

Identifying common issues with turbocharger oil drain connections can involve observing signs of oil leakage or reduced turbocharger performance. Troubleshooting may require inspecting the connection for signs of wear or damage and ensuring that it is securely fitted. Recommended maintenance practices include regular inspection of the oil drain connection as part of routine engine maintenance, cleaning or replacing it as necessary to ensure optimal performance and longevity of the component.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the automotive industry, with a history of producing high-quality engine components and systems. The company’s reputation is built on its commitment to innovation, quality, and reliability. Cummins’ extensive range of products and services caters to various industries, demonstrating its expertise and dedication to meeting the needs of its customers with reliable and efficient engine solutions.

Role of Part 3977615 Turbocharger Oil Drain Connection in Engine Systems

The Turbocharger Oil Drain Connection part 3977615 is an essential component in the efficient operation of turbocharger systems within various engine setups. This component is specifically designed to facilitate the drainage of oil from the turbocharger, ensuring that the lubrication system remains effective and that the turbocharger operates within optimal parameters.

Integration with Turbocharger Plumbing

In the context of turbocharger plumbing, the Turbocharger Oil Drain Connection plays a significant role. It is strategically positioned to connect the oil supply lines to the turbocharger, allowing for the circulation of lubricant that reduces friction and wear on moving parts. The drain connection ensures that any excess oil, which may accumulate due to centrifugal forces within the turbocharger, is efficiently removed. This prevents oil buildup, which could otherwise lead to performance degradation or even failure of the turbocharger.

Functionality within the Turbocharger System

When considering the turbocharger itself, the Oil Drain Connection is integral to maintaining the health of the turbocharger’s internal components. By allowing for the consistent drainage of oil, it helps in preventing oil coking, a condition where oil thickens and forms a solid or semi-solid residue. This residue can clog oil passages and bearings, leading to increased friction and potential turbocharger seizure.

Contribution to Overall Engine Performance

In the broader scope of engine systems, the efficient operation of the Turbocharger Oil Drain Connection contributes to the reliability and performance of the entire engine. By ensuring that the turbocharger is properly lubricated and free from excess oil, the connection helps in maintaining the turbocharger’s efficiency, which directly impacts the engine’s power output and fuel efficiency. Moreover, it aids in reducing the thermal and mechanical stress on the turbocharger, prolonging its service life and reducing the likelihood of unexpected failures.

Importance in Maintenance and Upgrades

For engineers and mechanics, understanding the role of the Turbocharger Oil Drain Connection is vital during maintenance and upgrades. Regular inspection and maintenance of this component can prevent issues related to oil management within the turbocharger, ensuring that the engine operates smoothly and efficiently. Additionally, when upgrading turbocharger systems, ensuring compatibility and proper installation of the Oil Drain Connection is key to maximizing the benefits of the upgrade.

Conclusion

The Turbocharger Oil Drain Connection part 3977615 plays a crucial role in the efficient operation of heavy-duty truck engines by ensuring effective oil management within the turbocharger system. Its design and functionality contribute to the turbocharger’s efficiency, reliability, and longevity, directly impacting the engine’s overall performance. Regular maintenance and proper installation of this part are essential for optimal engine operation and longevity.

-

Mananathan, R. (2022). Automobile Wheel Alignment and Wheel Balancing. SAE International.

↩ -

Wharton, A. J. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩ -

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ -

Schneider, W.-H. (2016). Pistons and Engine Testing. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.