This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

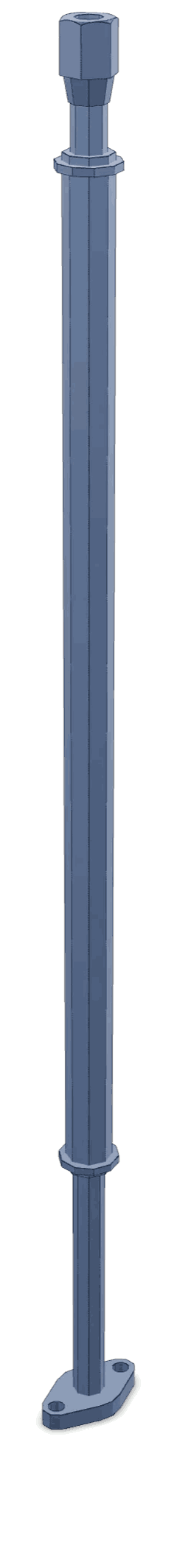

Introduction to Turbocharger Oil Drain Connection

Turbocharger oil drain connections are critical components in the lubrication system of turbocharged engines. These connections facilitate the drainage of oil from the turbocharger back to the engine’s oil sump, ensuring efficient and reliable operation. The turbocharger oil drain connection part #4913979, manufactured by Cummins, is a prime example of such a vital component.

Basic Concepts Related to Turbocharger Oil Drain Connection

A turbocharger oil drain connection manages the oil flow within the turbocharger. The turbocharger relies on oil for lubrication, cooling, and to drive the wastegate. After performing these functions, the oil must be drained back into the engine’s oil system. This is where the turbocharger oil drain connection becomes essential. It ensures that excess oil is returned to the oil sump, preventing oil starvation and overheating of the turbocharger 1.

Purpose of a Turbocharger Oil Drain Connection

The primary role of a turbocharger oil drain connection is to maintain the health and longevity of the turbocharger. By ensuring that excess oil is properly drained, it prevents oil from building up in the turbocharger, which can lead to increased wear and potential failure. Additionally, it helps maintain optimal engine performance by ensuring that the turbocharger operates within its designed parameters 2.

Operation of a Turbocharger Oil Drain Connection

The turbocharger oil drain connection operates by allowing oil to flow from the turbocharger to the engine’s oil system. This is typically achieved through a hose or pipe that connects the turbocharger to the oil sump. The connection must be secure and leak-free to prevent oil loss and maintain proper pressure within the lubrication system.

Troubleshooting and Maintenance of Turbocharger Oil Drain Connection

Regular maintenance and timely troubleshooting are essential to ensure the longevity and efficiency of the turbocharger oil drain connection. Here are some key points to consider:

-

Inspection for Leaks: Regularly inspect the turbocharger oil drain connection for any signs of leaks. Leaks can indicate a loose connection or a damaged hose, which can lead to oil loss and potential engine damage.

-

Cleaning: Ensure that the connection and associated hoses are clean and free from debris. Contaminants can cause blockages and reduce the efficiency of the oil drainage system.

-

Tightening Connections: Periodically check and tighten the connections to ensure they are secure. Loose connections can lead to oil leaks and reduced performance.

-

Replacement of Worn Parts: If any part of the turbocharger oil drain connection shows signs of wear or damage, it should be replaced promptly to prevent further issues.

Cummins and Quality Assurance

Cummins is a renowned manufacturer of heavy-duty truck parts, known for its commitment to quality and reliability. The turbocharger oil drain connection part #4913979 is designed to meet the highest standards of performance and durability. Cummins’ extensive experience in the industry ensures that their parts are built to withstand the rigors of heavy-duty applications, providing peace of mind to fleet operators and mechanics.

Educational Value for Engineers, Mechanics, Truck Drivers, and Fleet Operators

Understanding the importance and function of the turbocharger oil drain connection is crucial for engineers, mechanics, truck drivers, and fleet operators. Proper maintenance and troubleshooting of this component can prevent costly repairs and downtime, ensuring that the truck remains in optimal condition. By familiarizing themselves with the turbocharger oil drain connection, professionals in the industry can better maintain and service their vehicles, leading to improved performance and longevity.

Application in Cummins Engines

The Turbocharger Oil Drain Connection, identified by part number 4913979 and manufactured by Cummins, is a critical component in the engine’s lubrication system. This part ensures that oil is properly drained from the turbocharger, preventing oil accumulation that could lead to overheating and potential damage.

Application in Cummins Engines

The Turbocharger Oil Drain Connection is designed to fit seamlessly with various Cummins engines, ensuring optimal performance and reliability. Here are some of the engines where this part is applicable:

- K19 Engine Family

- The K19 engine series, known for its robust design and efficiency, incorporates the Turbocharger Oil Drain Connection to maintain the integrity of the turbocharger’s lubrication system. This part is essential in preventing oil from building up in the turbocharger, which could otherwise cause operational issues.

Importance in Engine Maintenance

Proper maintenance of the turbocharger oil system is crucial for the longevity and efficiency of the engine. The Turbocharger Oil Drain Connection plays a pivotal role in this by:

- Allowing for the controlled drainage of oil from the turbocharger.

- Preventing oil from entering areas where it is not needed, thus maintaining the balance of the lubrication system.

- Ensuring that the turbocharger operates within its optimal temperature range, thereby enhancing performance and reliability.

By integrating this component into the engine design, Cummins ensures that the turbocharger remains well-lubricated and free from oil-related complications, contributing to the overall durability and efficiency of the engine.

Understanding the Role of Part 4913979 Turbocharger Oil Drain Connection

In the context of engine systems, the part 4913979 Turbocharger Oil Drain Connection is an essential component that facilitates the efficient operation of the turbocharger. This part is integral to the oil management system of the turbocharger, ensuring that the oil used for lubrication and cooling is effectively drained and managed.

Integration with the Oil Drain Turbocharger

The Turbocharger Oil Drain Connection (part 4913979) is designed to interface directly with the oil drain system of the turbocharger. Its primary function is to provide a secure and reliable connection point for the oil drainage process. This ensures that the oil, which has been used to lubricate the turbocharger’s bearings and cool the turbine, is efficiently removed from the system. Proper drainage is vital for maintaining the integrity of the oil and preventing contamination, which can lead to decreased performance and potential damage to the turbocharger.

Interaction with Plumbing Components

In the broader engine system, the Turbocharger Oil Drain Connection also plays a significant role in the plumbing network. It connects to various plumbing components such as hoses, pipes, and filters, forming a comprehensive oil management system. This system is responsible for circulating oil to the turbocharger and then draining it back to the sump or reservoir. The connection ensures that the oil flow is uninterrupted and that any contaminants or debris are effectively filtered out, maintaining the quality of the oil and the efficiency of the turbocharger.

Turbocharger Functionality

The Turbocharger Oil Drain Connection is a key element in the overall functionality of the turbocharger. By ensuring that the oil is properly drained, it helps maintain the optimal operating temperature and lubrication of the turbocharger’s internal components. This, in turn, enhances the turbocharger’s performance, allowing it to spin at high speeds without overheating or suffering from excessive wear. The efficient management of oil through this connection is therefore fundamental to the longevity and reliability of the turbocharger.

Conclusion

The turbocharger oil drain connection part #4913979 by Cummins is a vital component in the lubrication system of turbocharged engines. Its role in maintaining the health and efficiency of the turbocharger cannot be overstated. Regular maintenance and proper troubleshooting are essential to ensure the longevity and performance of this part. Understanding its function and importance is crucial for engineers, mechanics, truck drivers, and fleet operators to maintain optimal engine performance and prevent costly repairs.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.