4938498

Turbocharger Oil Drain Connection

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbocharger Oil Drain Connection, identified by part number 4938498, is a component manufactured by Cummins, a well-established name in the automotive industry. This part is integral to the operation of heavy-duty truck engines, facilitating the efficient management of oil within the turbocharger system.

Basic Concepts

To understand the significance of the Turbocharger Oil Drain Connection, it is important to first grasp the fundamentals of turbochargers. Turbochargers are devices that increase the efficiency and power output of diesel engines by compressing the intake air before it enters the combustion chamber. This compression is achieved through a turbine driven by the engine’s exhaust gases. Oil lubrication plays a vital role in turbocharger operation, ensuring that moving parts within the turbocharger operate smoothly and efficiently 1.

Purpose of the Turbocharger Oil Drain Connection

The Turbocharger Oil Drain Connection serves a specific function within the turbocharger system. It is designed to facilitate the circulation and drainage of oil, which is crucial for lubricating the turbocharger’s moving components. By ensuring a consistent flow of oil, this connection helps maintain the turbocharger’s efficiency and longevity. It also allows for the periodic draining of oil, which is necessary for maintenance and to prevent the buildup of contaminants that could impair performance 2.

Key Features

The Turbocharger Oil Drain Connection is engineered with several key features that enhance its functionality. Constructed from durable materials, it is designed to withstand the high pressures and temperatures associated with turbocharger operation. The connection type is specifically tailored to ensure a secure and leak-free attachment to the turbocharger. Additionally, unique design elements may include anti-vibration mounts or specialized seals to further ensure reliability and performance 3.

Benefits

Incorporating the Turbocharger Oil Drain Connection into a heavy-duty truck engine offers several advantages. It contributes to improved engine performance by ensuring optimal turbocharger lubrication. This, in turn, enhances the reliability of the turbocharger and the engine as a whole. Furthermore, the design of the connection simplifies maintenance procedures, making it easier for technicians to drain and replace oil as needed 4.

Installation Process

Proper installation of the Turbocharger Oil Drain Connection is critical for its effective operation. The process involves several steps, including the preparation of the turbocharger and the connection site, the attachment of the drain connection using specified tools, and the verification of a secure and leak-free connection. Detailed instructions and any necessary tools or equipment should be consulted to ensure a correct installation 5.

Troubleshooting Common Issues

Common issues associated with the Turbocharger Oil Drain Connection may include leaks or blockages. Troubleshooting these problems involves a systematic approach to identify the source of the issue, whether it be a faulty seal, improper installation, or contamination within the oil system. Suggested steps for addressing these issues may include re-sealing connections, cleaning or replacing components, and ensuring proper oil levels and quality.

Maintenance Tips

Regular maintenance is key to ensuring the optimal performance and longevity of the Turbocharger Oil Drain Connection. This includes periodic checks for leaks, ensuring the connection remains secure, and adhering to recommended oil change intervals. Additionally, keeping the turbocharger and its components clean and free from contaminants will help maintain efficiency and prevent premature wear.

Cummins Overview

Cummins Inc. is a leader in the design, manufacture, and distribution of diesel and natural gas engines, as well as related technologies. With a rich history in the automotive industry, Cummins is renowned for its commitment to producing high-quality components that enhance the performance and reliability of engines across a wide range of applications. Their reputation is built on a foundation of innovation, quality, and customer satisfaction.

Turbocharger Oil Drain Connection (Part 4938498) Compatibility with Cummins Engines

The Turbocharger Oil Drain Connection, identified by the part number 4938498, is a critical component in the lubrication system of various Cummins engines. This part ensures that oil is properly drained from the turbocharger, maintaining optimal engine performance and longevity.

ISB/ISD4.5 CM2150 B119

In the ISB/ISD4.5 CM2150 B119 engine, the Turbocharger Oil Drain Connection is essential for managing the oil flow within the turbocharger. This engine is known for its robust design and efficiency, and the proper functioning of the oil drain connection is crucial for maintaining the turbocharger’s lubrication and preventing oil contamination.

QSB4.5 CM850 (CM2850)

Similarly, in the QSB4.5 CM850 (CM2850) engine, the Turbocharger Oil Drain Connection plays a vital role in the engine’s lubrication system. This engine variant is designed for durability and performance, and the oil drain connection ensures that the turbocharger operates smoothly by facilitating the controlled drainage of oil.

The Turbocharger Oil Drain Connection is engineered to fit seamlessly with these engines, ensuring that oil is efficiently drained from the turbocharger. This part is a critical component in maintaining the health and efficiency of the engine, and its compatibility with the specified engine models is well-established.

Role of Part 4938498 Turbocharger Oil Drain Connection in Engine Systems

The Turbocharger Oil Drain Connection, identified as part 4938498, is integral to the efficient operation and maintenance of engine systems that incorporate turbochargers. This component is specifically designed to facilitate the drainage of oil from the turbocharger, ensuring that the lubrication system remains effective and that contaminants are regularly removed.

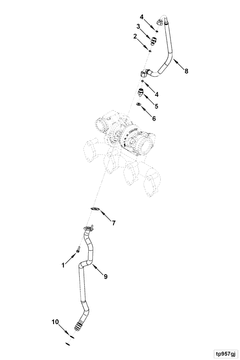

Integration with Turbocharger Plumbing

In the context of turbocharger plumbing, the Turbocharger Oil Drain Connection serves as a vital junction. It is strategically placed to allow for the periodic discharge of oil that has circulated through the turbocharger’s bearing system. This process is essential for maintaining the integrity of the lubrication, as it prevents the buildup of sludge and other particulates that can impair performance.

Functionality within the Turbocharger System

Within the turbocharger system, the Turbocharger Oil Drain Connection is connected to the turbocharger’s oil supply lines. It is typically found at the lowest point of the turbocharger’s oil circuit, which is a deliberate design choice to ensure that all oil can be effectively drained. This connection point is also where maintenance personnel will attach a drain pan or container during service intervals to collect the used oil.

Interaction with Engine Lubrication System

The Turbocharger Oil Drain Connection also interacts with the engine’s lubrication system. It is often connected to the engine’s oil return line, allowing the drained oil to be returned to the sump or oil pan. This ensures that the oil can be filtered and recirculated, conserving resources and maintaining the engine’s lubrication efficiency.

Importance in Maintenance Routines

During routine maintenance, the Turbocharger Oil Drain Connection is a key access point. Mechanics and engineers use this component to perform oil changes on the turbocharger, which is a necessary procedure to ensure the longevity and performance of the turbocharger. The ease of access provided by this connection simplifies the maintenance process and reduces downtime.

Role in Diagnostic Procedures

In diagnostic procedures, the Turbocharger Oil Drain Connection can also play a role. By examining the condition of the oil that is drained from the turbocharger, technicians can gain insights into the health of the turbocharger’s internal components. The presence of metal shavings or an unusual consistency in the oil can indicate wear or other issues that require attention.

Conclusion

The Turbocharger Oil Drain Connection (part 4938498) is a component that enhances the functionality and maintainability of engine systems with turbochargers. Its role in facilitating oil drainage, interacting with the turbocharger and engine lubrication systems, and aiding in maintenance and diagnostics underscores its importance in the overall performance and reliability of the engine.

-

Hilgers, Michael. Entire Vehicle: Second Edition. Springer Nature, 2023.

↩ -

Reif, Konrad. Automotive Mechatronics. Springer Vieweg, 2015.

↩ -

Rajamani, Rajesh. Vehicle Dynamics and Control. Springer, 2005.

↩ -

Fehan, Douglas R. Design of Racing and High-Performance Engines 2004-2013. SAE International, 2013.

↩ -

Cummins Inc. QSNT14 CM876 N102, Service Manual (4325993).

↩

SPECIFICATIONS

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| O Ring Seal | 2 | 3928624 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.