This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

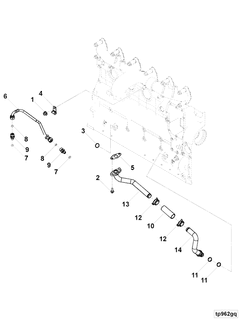

The Turbocharger Oil Drain Connection, identified by Part #4992246, is a component manufactured by Cummins, a leader in the commercial truck industry. This part is integral to the operation of heavy-duty truck engines, facilitating the efficient management of oil within the turbocharger system.

Basic Concepts

Turbochargers are devices that enhance engine performance by compressing the intake air before it enters the combustion chamber, thereby increasing the engine’s power output. Oil lubrication is vital for turbocharger operation, as it reduces friction between moving parts, dissipates heat, and prevents wear 1. Effective oil management within the turbocharger system is crucial for maintaining performance and longevity.

Purpose and Function

The Turbocharger Oil Drain Connection plays a role in the turbocharger system by enabling the circulation and drainage of oil. It ensures that oil is properly directed to lubricate the turbocharger’s moving components and is efficiently drained away to prevent buildup and contamination. This connection is part of the system that maintains optimal oil levels and flow, contributing to the turbocharger’s reliable operation.

Key Features

The Turbocharger Oil Drain Connection is designed with precision to ensure compatibility and effectiveness. It is constructed from durable materials that can withstand the high temperatures and pressures within the turbocharger environment. The connection types are engineered to provide a secure fit, preventing leaks and ensuring consistent oil flow. Unique design elements may include anti-corrosion coatings and reinforced seals to enhance durability and performance.

Benefits

The Turbocharger Oil Drain Connection offers several advantages. It contributes to improved turbocharger longevity by ensuring consistent lubrication and preventing oil-related issues. Enhanced engine performance is another benefit, as proper oil management within the turbocharger system supports efficient operation. Additionally, the design of this connection simplifies maintenance procedures, making it easier for technicians to service the turbocharger system.

Installation and Compatibility

Proper installation of the Turbocharger Oil Drain Connection is important for ensuring its effectiveness. Specific requirements may include torque specifications for tightening connections and ensuring that all seals are properly seated. Compatibility with various engine models and turbocharger systems should be verified to ensure optimal performance and integration within the engine’s oil management system.

Maintenance and Troubleshooting

Regular maintenance practices are recommended to ensure the optimal performance of the Turbocharger Oil Drain Connection. This may include periodic inspections for leaks, corrosion, or wear, and cleaning or replacing components as necessary. Common issues that may arise include oil leaks or blockages, which can often be addressed through careful inspection and maintenance.

Safety Considerations

When working with the Turbocharger Oil Drain Connection, it is important to observe safety guidelines and precautions. This includes ensuring that the engine is cool before beginning any maintenance or installation procedures, using appropriate personal protective equipment, and following manufacturer recommendations for handling and installation to prevent injury or damage.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product portfolio and history of excellence make it a trusted name in the automotive and heavy-duty truck sectors.

Turbocharger Oil Drain Connection (Part 4992246) Compatibility with Cummins Engines

The Turbocharger Oil Drain Connection (Part 4992246) by Cummins is designed to fit seamlessly with several of their engine models. This part is crucial for maintaining the health and efficiency of the turbocharger by ensuring proper oil drainage.

ISB/ISD6.7 CM2150 SN

The Turbocharger Oil Drain Connection is compatible with the ISB/ISD6.7 CM2150 SN engines. This part ensures that the turbocharger’s oil is effectively drained, preventing oil accumulation that could lead to performance issues.

QSB6.7 CM850 (CM2850)

For the QSB6.7 CM850 (CM2850) engines, the Turbocharger Oil Drain Connection is engineered to fit precisely. This ensures that the oil is drained efficiently, maintaining the turbocharger’s operational integrity and extending its lifespan.

QSB7 CM2880 B117

The Turbocharger Oil Drain Connection also fits the QSB7 CM2880 B117 engines. This part is essential for ensuring that the turbocharger operates smoothly by preventing oil buildup, which can cause wear and tear over time.

By ensuring proper oil drainage, the Turbocharger Oil Drain Connection (Part 4992246) helps maintain the performance and longevity of these Cummins engines.

Role of Part 4992246 Turbocharger Oil Drain Connection in Engine Systems

The Turbocharger Oil Drain Connection (Part 4992246) is an integral component in the maintenance and operation of turbocharger systems within various engine setups. This component facilitates the efficient drainage of oil from the turbocharger, ensuring that the lubrication system remains clean and free from contaminants.

Integration with Turbocharger Systems

In turbocharger systems, the oil drain connection is positioned to allow for the periodic removal of oil that has been used to lubricate the turbocharger’s bearings and other moving parts. This process is essential for maintaining the turbocharger’s performance and longevity. The connection point is typically located at the lower section of the turbocharger housing, where oil accumulates after circulating through the system.

Interaction with Plumbing Components

The Turbocharger Oil Drain Connection interfaces with the engine’s plumbing system to direct the drained oil back into the sump or a designated collection area. This ensures that the oil can be properly filtered and recirculated, or disposed of according to environmental regulations. The connection must be securely fitted to prevent leaks, which could lead to oil loss and potential engine damage.

Maintenance and Operational Benefits

By incorporating the Turbocharger Oil Drain Connection, mechanics and engineers can perform routine maintenance more effectively. Regular oil changes help in reducing the buildup of sludge and other deposits that can impair turbocharger efficiency. Additionally, the connection allows for easier diagnosis of potential issues within the turbocharger, as the condition of the drained oil can provide insights into the health of the system.

Enhanced System Reliability

The presence of a dedicated oil drain connection enhances the overall reliability of the turbocharger and the engine system. It allows for proactive maintenance practices that can prevent catastrophic failures and extend the service life of the turbocharger. Furthermore, it supports consistent performance by ensuring that the turbocharger operates within optimal lubrication parameters.

Conclusion

The Turbocharger Oil Drain Connection (Part 4992246) plays a significant role in the efficient operation and maintenance of turbocharger systems. By facilitating the drainage of oil, it ensures that the turbocharger remains lubricated and free from contaminants, thereby enhancing engine performance and reliability. Proper installation, regular maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this Cummins part.

-

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.