This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbocharger Oil Drain Connection, identified by Part #5270679, is a component manufactured by Cummins, a well-established name in the automotive industry. This part is integral to the operation of heavy-duty truck engines, facilitating the efficient management of oil within the turbocharger system. Proper oil management is vital for maintaining the performance and longevity of the turbocharger, making the Turbocharger Oil Drain Connection a significant element in the engine’s overall system 1.

Basic Concepts of Turbocharger Oil Drain Connection

Turbocharger oil drain connections serve a fundamental role in the turbocharger system by allowing for the controlled drainage of oil. Turbochargers, which compress the air entering the engine to improve efficiency and power output, require lubrication to operate smoothly. The oil drain connection ensures that excess oil, which can accumulate within the turbocharger, is efficiently removed. This process is crucial for preventing oil buildup, which can lead to decreased turbocharger efficiency and potential damage 2. Effective oil management through the drain connection helps maintain the turbocharger’s performance and extends its operational life.

Role and Function of the Turbocharger Oil Drain Connection

The Turbocharger Oil Drain Connection plays a specific role in the operation of a truck’s engine by facilitating the drainage of oil from the turbocharger. This part is designed to allow for the periodic release of oil that has lubricated the turbocharger’s moving parts. By enabling the drainage of excess oil, the connection helps prevent oil buildup within the turbocharger, ensuring that the component operates efficiently. This function is vital for maintaining the turbocharger’s performance, as oil buildup can lead to increased friction and heat, potentially causing damage to the turbocharger and reducing its effectiveness 3.

Key Features

The Turbocharger Oil Drain Connection is characterized by several key features that enhance its performance and reliability. Its design is tailored to fit seamlessly within the turbocharger system, ensuring a secure and efficient connection. The materials used in its construction are chosen for their durability and resistance to the high temperatures and pressures encountered within the engine. Additionally, the connection may feature unique characteristics such as a precise threading or sealing mechanism to ensure a leak-free operation, further contributing to the turbocharger’s efficiency and longevity.

Benefits of Using the Turbocharger Oil Drain Connection

Incorporating the Turbocharger Oil Drain Connection into a truck’s engine system offers several advantages. By facilitating efficient oil drainage, this part contributes to improved turbocharger efficiency, as it helps maintain optimal lubrication without allowing for excess oil buildup. This can lead to reduced maintenance requirements, as the turbocharger is less likely to suffer from oil-related issues. Furthermore, the enhanced performance of the turbocharger, thanks to effective oil management, can contribute to overall engine performance, potentially improving fuel efficiency and power output.

Troubleshooting and Maintenance Suggestions

To ensure the optimal performance and longevity of the Turbocharger Oil Drain Connection, it is important to be aware of common issues and employ recommended maintenance practices. Regular inspection of the connection for signs of wear, leaks, or damage is advisable. If issues are detected, such as oil leaks or difficulty in draining oil, troubleshooting may involve checking the connection’s fit within the turbocharger system, ensuring there are no obstructions, and verifying that the sealing mechanism is intact. Maintenance practices should include following the manufacturer’s guidelines for oil change intervals and using the recommended type of oil to ensure compatibility with the turbocharger system.

Cummins: Manufacturer Overview

Cummins, the manufacturer of the Turbocharger Oil Drain Connection, has a long-standing reputation in the automotive industry for producing high-quality engine components. With a history of innovation and commitment to excellence, Cummins has established itself as a trusted name among professionals and enthusiasts alike. The company’s dedication to quality is evident in its engine components, which are designed to meet the demanding requirements of heavy-duty applications. Cummins’ reputation for reliability and performance makes its products, including the Turbocharger Oil Drain Connection, a preferred choice for those seeking to maintain and enhance the efficiency of their vehicle’s engine system.

Turbocharger Oil Drain Connection for Cummins Engines

The Turbocharger Oil Drain Connection, part number 5270679, is a critical component in the lubrication system of certain Cummins engines. This part is designed to facilitate the drainage of oil from the turbocharger, ensuring that the turbocharger operates smoothly and efficiently.

Application in Cummins Engines

The Turbocharger Oil Drain Connection is compatible with several Cummins engine models, including:

- QSB6.7 CM2250

This part is integral to the maintenance and operation of these engines, ensuring that the turbocharger’s oil is properly drained and managed. The design and placement of this connection are tailored to fit seamlessly within the engine’s architecture, providing a reliable and efficient means of oil drainage.

Importance in Engine Performance

Proper oil drainage from the turbocharger is essential for maintaining engine performance and longevity. The Turbocharger Oil Drain Connection helps prevent oil buildup, which can lead to increased wear and potential damage to the turbocharger. By ensuring that oil is effectively drained, this component contributes to the overall reliability and efficiency of the engine.

Installation and Maintenance

When installing or replacing the Turbocharger Oil Drain Connection, it is important to follow the manufacturer’s guidelines to ensure a proper fit and function. Regular maintenance checks should be performed to verify that the connection is secure and free from leaks, which can compromise the engine’s lubrication system.

Role of Part 5270679 Turbocharger Oil Drain Connection in Engine Systems

The Turbocharger Oil Drain Connection, identified by part number 5270679, is an essential component in the turbocharger plumbing system of various engine setups. Its primary function is to facilitate the drainage of oil from the turbocharger, ensuring that the lubrication system remains efficient and that oil does not accumulate excessively within the turbocharger housing.

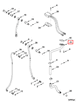

Integration with Turbocharger Plumbing

In the context of turbocharger plumbing, the Turbocharger Oil Drain Connection is strategically positioned to interface with the oil return lines. This connection point allows for the controlled release of oil back into the engine’s lubrication circuit, preventing oil buildup that could lead to performance issues or damage.

Interaction with Turbocharger Components

The Turbocharger Oil Drain Connection works in conjunction with several key components within the turbocharger system:

-

Turbocharger Bearings: Proper oil drainage is vital for maintaining the integrity and performance of the turbocharger’s bearings. Efficient oil management ensures that the bearings remain well-lubricated without being submerged in excess oil, which could cause overheating and premature wear.

-

Oil Supply Lines: The connection point is typically located at the end of the oil supply lines, allowing for a seamless transition from oil delivery to oil return. This ensures a consistent flow of lubricant to the turbocharger’s moving parts while facilitating the removal of used oil.

-

Drainage Pathways: The Turbocharger Oil Drain Connection is designed to align with the turbocharger’s internal drainage pathways. These pathways are engineered to guide oil away from critical components and toward the drain connection, ensuring that oil is efficiently returned to the engine’s sump or oil reservoir.

Importance in Maintenance and Performance

Regular maintenance of the Turbocharger Oil Drain Connection is essential for the overall health of the turbocharger system. Ensuring that this component is free from blockages and properly sealed contributes to the longevity and reliability of the turbocharger. Additionally, proper drainage helps maintain optimal oil levels, which is fundamental for the turbocharger’s efficient operation and the engine’s performance.

Conclusion

In summary, the Turbocharger Oil Drain Connection (part 5270679) plays a significant role in the turbocharger plumbing system by ensuring efficient oil management, which is essential for the sustained performance and reliability of the turbocharger and the engine as a whole.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.