5289807

Turbocharger Oil Drain Connection

Cummins®

IN STOCK

1 is currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbocharger Oil Drain Connection, identified by Part #5289807, is a component manufactured by Cummins, a renowned name in the automotive industry. This part is integral to the operation of heavy-duty truck engines, particularly those equipped with turbochargers. Its role is to facilitate the drainage of oil from the turbocharger, ensuring the system operates efficiently and maintains longevity.

Basic Concepts of Turbocharger Oil Drain Connection

To understand the Turbocharger Oil Drain Connection, it is important to grasp the fundamental principles of turbochargers. Turbochargers are devices that increase an engine’s power output by forcing extra air into the combustion chamber. This process, however, generates heat and requires lubrication, which is provided by engine oil. The oil circulates through the turbocharger, cooling and lubricating its components. The Turbocharger Oil Drain Connection plays a role in this system by allowing the used oil to be drained away, preventing buildup and ensuring the turbocharger operates within optimal parameters 1.

Purpose and Role of the Turbocharger Oil Drain Connection

The Turbocharger Oil Drain Connection serves a specific purpose in the operation of a truck engine. It ensures that oil, after lubricating and cooling the turbocharger, is efficiently drained away. This process is vital for maintaining the turbocharger’s efficiency and extending its operational life. By facilitating the removal of used oil, the connection helps prevent oil degradation and the formation of deposits, which can impair turbocharger performance 2.

Key Features of the Turbocharger Oil Drain Connection

The design and construction of the Turbocharger Oil Drain Connection are tailored to meet the demanding requirements of heavy-duty truck engines. It is constructed from durable materials that can withstand high temperatures and pressures. The build quality ensures a secure fit and reliable operation. Unique attributes, such as precise threading and sealing mechanisms, enhance its performance by ensuring a tight seal and preventing oil leaks.

Benefits of Using the Turbocharger Oil Drain Connection

Incorporating the Turbocharger Oil Drain Connection into a truck’s engine system offers several advantages. It contributes to improved engine performance by ensuring the turbocharger operates efficiently. Reduced maintenance needs are another benefit, as the part helps prevent oil-related issues that can lead to turbocharger failure. Additionally, by facilitating proper oil drainage, the connection plays a role in enhancing the turbocharger’s longevity 3.

Troubleshooting and Maintenance Suggestions

Common issues associated with the Turbocharger Oil Drain Connection may include oil leaks or blockages. Troubleshooting steps involve inspecting the connection for signs of wear or damage and ensuring it is properly installed. Regular maintenance, such as checking for leaks and ensuring the connection is free from obstructions, is recommended to ensure optimal performance and longevity of the part.

Integration with Turbocharger Systems

The Turbocharger Oil Drain Connection is designed to integrate seamlessly with various turbocharger systems, particularly those used in Cummins engines. Compatibility is a key consideration, ensuring the connection fits securely and functions as intended within the turbocharger system. Installation considerations include proper alignment and sealing to ensure efficient oil drainage and prevent leaks.

Impact on Engine Performance

The proper function of the Turbocharger Oil Drain Connection has a noticeable effect on overall engine performance. By ensuring efficient oil drainage, the connection helps maintain the turbocharger’s efficiency, which in turn contributes to the engine’s power output and fuel efficiency. Data and case studies may illustrate the positive impact of this part on engine performance and reliability.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a rich history in the automotive industry, Cummins is particularly renowned for its diesel engines and components. The company’s reputation for quality, innovation, and reliability is built on a commitment to excellence and customer satisfaction, making it a preferred choice for heavy-duty truck engines and components.

Turbocharger Oil Drain Connection for Cummins Engines

The Turbocharger Oil Drain Connection part number 5289807, manufactured by Cummins, is a critical component in maintaining the efficiency and longevity of several Cummins engine models. This part is designed to facilitate the drainage of oil from the turbocharger, ensuring that the turbocharger operates smoothly and without excessive oil buildup.

QSB4.5 CM2250 EC

The QSB4.5 CM2250 EC engine is one of the models that utilize the Turbocharger Oil Drain Connection part number 5289807. This part is integral to the engine’s lubrication system, specifically designed to manage the oil flow to and from the turbocharger. Proper drainage of oil is essential to prevent oil from entering the turbine and compressor sections, which can lead to inefficient operation and potential damage.

Grouping of Engines

In the broader context, the Turbocharger Oil Drain Connection part number 5289807 is compatible with various Cummins engines that share similar design principles and lubrication requirements. This part is engineered to fit seamlessly into the turbocharger system of these engines, ensuring that oil is effectively managed and drained as needed. The compatibility of this part across different engine models highlights its versatility and importance in maintaining the overall health of the engine.

Role of Part 5289807 Turbocharger Oil Drain Connection in Engine Systems

The Turbocharger Oil Drain Connection, identified by part number 5289807, is an integral component in the maintenance and operation of turbocharger systems within engine assemblies. This part facilitates the essential function of draining oil from the turbocharger, ensuring that the lubrication system remains efficient and that the turbocharger operates within optimal parameters.

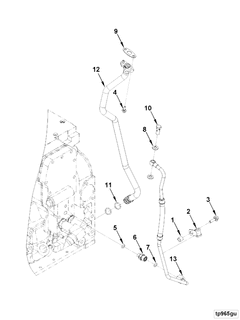

Integration with Turbocharger Plumbing

In the context of turbocharger plumbing, the Turbocharger Oil Drain Connection serves as a vital junction. It is strategically positioned to allow for the periodic removal of oil that has circulated through the turbocharger’s bearing system. This process is fundamental in preventing the accumulation of contaminants and degradation products that can form in the oil over time, which could otherwise lead to decreased turbocharger efficiency and potential failure.

Interaction with the Turbocharger

When considering the turbocharger itself, the Turbocharger Oil Drain Connection is directly linked to the turbocharger’s oil supply and return lines. It ensures that after oil has been used to lubricate the turbocharger’s rotating components, it can be efficiently drained away. This not only helps in maintaining the cleanliness of the oil but also assists in the overall thermal management of the turbocharger, as oil that has absorbed heat during operation is removed and replaced with cooler oil.

Contribution to Overall Engine Performance

The effective operation of the Turbocharger Oil Drain Connection contributes to the turbocharger’s ability to compress intake air without excessive heat buildup, which is a common challenge in turbocharged engines. By ensuring that the oil system within the turbocharger is maintained in a clean and efficient state, the Turbocharger Oil Drain Connection indirectly supports the engine’s power output, fuel efficiency, and longevity.

Conclusion

In summary, the Turbocharger Oil Drain Connection (part 5289807) plays a significant role in the turbocharger’s lubrication system, facilitating the removal of used oil and contributing to the turbocharger’s—and consequently, the engine’s—overall performance and reliability.

-

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ -

Boyce, Meherwan P. Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing, 2002.

↩ -

Bari, Saiful. Diesel Engine Combustion, Emissions and Condition Monitoring. InTech, 2013.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.