This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbocharger Oil Drain Connection, identified by Part #5291355, is a component manufactured by Cummins, a leading name in the automotive and heavy-duty truck industry. This part is integral to the turbocharger system in heavy-duty truck engines, facilitating efficient oil circulation and drainage. Understanding its function and significance is key to maintaining optimal engine performance and reliability.

Basic Concepts

Turbochargers are devices that increase an engine’s power output by forcing extra air into the combustion chamber. In diesel engines, turbochargers play a vital role by enhancing fuel efficiency and power. Oil lubrication is crucial for turbocharger operation, as it reduces friction and wear on moving parts, ensuring smooth and efficient performance 1.

Purpose of the Turbocharger Oil Drain Connection

The Turbocharger Oil Drain Connection serves a specific function within the turbocharger system. It is designed to facilitate the circulation and drainage of oil, which is essential for lubricating the turbocharger’s moving components. This connection ensures that oil is efficiently directed to where it is needed and then drained away, maintaining a clean and well-lubricated system.

Key Features

The Turbocharger Oil Drain Connection is engineered with specific design and construction features. It is typically made from durable materials to withstand the high temperatures and pressures within the engine compartment. The connection may include various types of fittings to ensure a secure and leak-free attachment to the turbocharger and the oil system. Unique design elements may also be incorporated to enhance its functionality and ease of maintenance.

Benefits

Incorporating the Turbocharger Oil Drain Connection into a turbocharger system offers several advantages. It contributes to improved engine performance by ensuring consistent oil lubrication. This, in turn, enhances the reliability of the turbocharger and the overall engine system. Additionally, the design of the connection can simplify maintenance procedures, making it easier to inspect, clean, and service the turbocharger system.

Installation and Compatibility

Proper installation of the Turbocharger Oil Drain Connection is crucial for its effective operation. Guidelines for installation may vary depending on the specific engine model. It is important to follow manufacturer recommendations to ensure compatibility and optimal performance. Specific requirements or considerations for different engine models should be taken into account during the installation process.

Maintenance and Troubleshooting

Routine maintenance of the Turbocharger Oil Drain Connection is important to ensure its longevity and performance. This may include regular inspection intervals to check for signs of wear or damage, cleaning procedures to remove any contaminants, and following recommended maintenance schedules. Common troubleshooting steps can help address potential issues, ensuring the connection continues to function effectively.

Common Issues and Solutions

Typical problems associated with the Turbocharger Oil Drain Connection may include leaks or blockages. These issues can often be resolved through proper maintenance and timely repairs. Preventive measures, such as regular inspections and adhering to maintenance schedules, can help avoid these common problems.

Cummins Overview

Cummins Inc. is a well-established company in the automotive industry, known for its wide range of products including engines, filtration, and power generation equipment. With a strong reputation for quality and reliability, Cummins has been a trusted name in the industry for many years, providing innovative solutions for various applications 2.

Turbocharger Oil Drain Connection for Cummins Engines

The Turbocharger Oil Drain Connection part number 5291355, manufactured by Cummins, is a critical component in the lubrication system of certain Cummins engines. This part is designed to facilitate the drainage of oil from the turbocharger, ensuring that the turbocharger operates efficiently and reliably.

Application in Cummins Engines

QSL9 CM2250 and QSL9 CM2350 L102

The Turbocharger Oil Drain Connection part 5291355 is compatible with the Cummins QSL9 CM2250 and QSL9 CM2350 L102 engines. These engines are known for their robust performance and are widely used in various industrial applications. The part ensures that the turbocharger’s oil is properly drained, preventing oil accumulation that could lead to overheating and potential damage to the turbocharger.

Compatibility and Installation

When installing the Turbocharger Oil Drain Connection part 5291355 in the QSL9 CM2250 and QSL9 CM2350 L102 engines, it is essential to follow the manufacturer’s guidelines to ensure a proper fit and function. This part is engineered to integrate seamlessly with the existing oil drainage system of these engines, providing a reliable connection that supports the efficient operation of the turbocharger.

By using the Turbocharger Oil Drain Connection part 5291355, technicians and operators can maintain the integrity of the turbocharger’s lubrication system, contributing to the overall performance and longevity of the engine.

Role of Part 5291355 Turbocharger Oil Drain Connection in Engine Systems

The Turbocharger Oil Drain Connection part 5291355 is integral to the efficient operation and maintenance of turbocharger systems within engine setups. This component facilitates the necessary connection for draining oil from the turbocharger, ensuring that the lubrication system remains clean and effective.

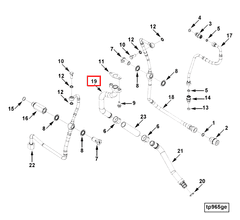

Integration with Turbocharger Plumbing

In the context of turbocharger plumbing, the 5291355 connection serves as a vital junction. It allows for the periodic removal of oil that has been used to lubricate the turbocharger’s moving parts. This is essential for maintaining the integrity of the oil, preventing contamination, and ensuring that the turbocharger operates smoothly.

Function within the Turbocharger System

Within the turbocharger itself, the oil drain connection is part of a larger system designed to manage the lubrication and cooling of the turbocharger’s components. By providing a reliable means to drain oil, it helps in:

- Reducing Wear and Tear: Regular oil changes facilitated by this connection help in minimizing wear on the turbocharger’s bearings and other moving parts.

- Enhancing Performance: Clean oil ensures optimal lubrication, which is vital for the turbocharger to operate at peak efficiency.

- Preventing Failures: By allowing for the removal of old or contaminated oil, the connection helps in preventing potential failures that could arise from poor lubrication.

Importance in Overall Engine Maintenance

The role of the 5291355 Turbocharger Oil Drain Connection extends beyond just the turbocharger. In the broader context of engine maintenance, it contributes to:

- Extended Component Life: By ensuring that the turbocharger is properly lubricated and maintained, the overall lifespan of the engine components is increased.

- Improved Reliability: A well-maintained turbocharger leads to more reliable engine performance, reducing the likelihood of unexpected downtime.

- Efficient Operation: Proper lubrication and maintenance of the turbocharger contribute to the engine’s overall efficiency, ensuring that it operates within optimal parameters.

Conclusion

In summary, the Turbocharger Oil Drain Connection part 5291355 is a key component in the maintenance and operation of turbocharger systems, playing a significant role in the longevity and performance of engine systems. Proper installation, maintenance, and understanding of its function are essential for ensuring optimal engine performance and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.