5293259

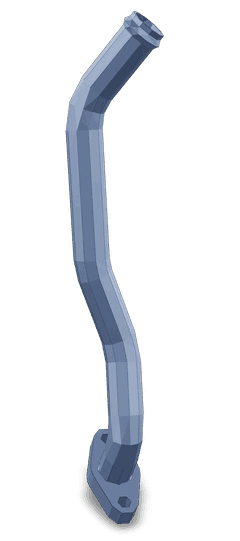

Turbocharger Oil Drain Connection

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbocharger Oil Drain Connection, identified by Part #5293259 and manufactured by Cummins, is a component integral to the operation of heavy-duty truck engines. This part facilitates the efficient management of oil within the turbocharger system, contributing to the overall performance and longevity of the engine.

Basic Concepts of Turbocharger Oil Drain Connection

Turbochargers are devices that increase an engine’s power output by forcing extra air into the combustion chamber. This process, known as forced induction, allows more fuel to be burned, resulting in increased power without a corresponding increase in engine size 1. The turbocharger oil drain connection plays a role in maintaining the efficiency of the turbocharger by ensuring that oil used for lubrication and cooling is properly managed and drained.

Purpose and Function of the Turbocharger Oil Drain Connection

The Turbocharger Oil Drain Connection is designed to facilitate the drainage of oil from the turbocharger. This process is vital for removing contaminants and ensuring that the oil remains clean and effective for lubrication and cooling purposes 2. By maintaining optimal oil conditions, the turbocharger can operate more efficiently, contributing to enhanced engine performance and reliability.

Key Features

This Cummins part is constructed from durable materials that are resistant to the high temperatures and pressures encountered in heavy-duty truck engines. Its design incorporates precise engineering to ensure a secure fit and reliable operation. Unique attributes of this part include its robust construction and ease of installation, which contribute to its performance and durability.

Benefits of Using the Turbocharger Oil Drain Connection

Utilizing the Turbocharger Oil Drain Connection offers several advantages. It contributes to improved engine performance by ensuring that the turbocharger operates under optimal conditions. Additionally, it enhances turbocharger longevity by facilitating the removal of contaminants from the oil. Simplified maintenance procedures are another benefit, as the design of this part allows for easy access and efficient oil drainage.

Installation and Compatibility

Proper installation of the Turbocharger Oil Drain Connection is crucial for ensuring its effective operation. Guidelines for installation include verifying compatibility with the specific truck model and engine type to ensure a proper fit and function 3. Attention to manufacturer recommendations during installation can help prevent issues and ensure the part operates as intended.

Maintenance and Troubleshooting

Routine maintenance practices for the Turbocharger Oil Drain Connection include regular inspection for signs of wear or damage and ensuring that the connection remains secure. Troubleshooting tips for addressing common issues, such as leaks or blockages, involve checking for proper installation, ensuring the connection is tight, and verifying that the oil drainage path is clear of obstructions.

Common Issues and Solutions

Frequent problems associated with turbocharger oil drain connections may include leaks or blockages. Solutions for resolving these issues effectively involve inspecting the connection for damage, ensuring it is properly installed, and clearing any obstructions in the oil drainage path. Regular maintenance and adherence to manufacturer guidelines can help prevent these issues.

Manufacturer - Cummins

Cummins is recognized as a leading manufacturer of diesel engines and related components. The company’s reputation for quality, innovation, and reliability in the automotive industry is supported by a commitment to producing parts that meet the demanding requirements of heavy-duty applications. The Turbocharger Oil Drain Connection is a testament to Cummins’ dedication to enhancing engine performance and durability.

Role of Part 5293259 Turbocharger Oil Drain Connection in Engine Systems

The Turbocharger Oil Drain Connection, part 5293259, is integral to the efficient operation of turbocharger plumbing systems. This component facilitates the drainage of oil from the turbocharger, ensuring that the lubrication system remains effective and that oil does not accumulate to problematic levels.

In the context of turbocharger plumbing, the oil drain connection works in conjunction with the oil supply line, oil return line, and the turbocharger itself. When the engine is running, oil is pumped through the supply line to lubricate the turbocharger’s bearings and other moving parts. After lubrication, the oil needs to be returned to the sump or oil pan to be recirculated. This is where the oil drain connection plays a significant role.

The oil drain connection is typically located at the lowest point of the turbocharger to allow gravity to assist in the drainage process. It connects to the oil return line, which carries the used oil back to the engine’s lubrication system. This ensures a continuous cycle of oil flow, maintaining optimal lubrication and cooling for the turbocharger.

Additionally, the oil drain connection helps in preventing oil leaks and maintaining system pressure. By efficiently draining oil, it reduces the risk of oil buildup, which can lead to increased pressure within the turbocharger housing. This, in turn, helps in sustaining the turbocharger’s performance and longevity.

Conclusion

In summary, the Turbocharger Oil Drain Connection, part 5293259, is a key component in the turbocharger plumbing system, ensuring proper oil circulation, preventing leaks, and maintaining system integrity. Its role in the efficient operation of heavy-duty truck engines underscores the importance of proper installation, maintenance, and understanding of its function within the engine system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.