5306012

Turbocharger Oil Drain Connection

Cummins®

AVAILABLE

5 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbocharger Oil Drain Connection (5306012) by Cummins is a component designed to facilitate the drainage of oil from the turbocharger system in heavy-duty trucks. This part is integral to maintaining the efficiency and longevity of the turbocharger, ensuring optimal engine performance.

Basic Concepts

Turbochargers are devices that increase the power output of diesel engines by compressing the intake air before it enters the combustion chamber. This process enhances the engine’s efficiency and power. Oil lubrication is vital for turbocharger operation, as it reduces friction between moving parts, dissipates heat, and removes contaminants, thereby ensuring smooth and reliable performance 1.

Purpose of the Turbocharger Oil Drain Connection

The Turbocharger Oil Drain Connection plays a role in the turbocharger system by allowing for the periodic drainage of oil. This process is important for removing contaminants and ensuring that fresh, clean oil circulates through the system. Proper oil circulation helps maintain the condition of turbocharger components, contributing to efficient operation and longevity 2.

Key Features

The 5306012 Turbocharger Oil Drain Connection is constructed with durable materials to withstand the high pressures and temperatures within the turbocharger system. Its design includes specific connection types that ensure a secure fit and reliable operation. Unique design elements may include anti-leak features and easy-access points for maintenance, enhancing the overall functionality and ease of use.

Benefits

The Turbocharger Oil Drain Connection offers several advantages. It contributes to improved engine performance by ensuring that the turbocharger operates with clean oil. This maintenance practice can extend the lifespan of the turbocharger and simplify maintenance procedures by providing an efficient means to drain and replace oil.

Installation and Compatibility

For the proper installation of the Turbocharger Oil Drain Connection, it is important to follow manufacturer guidelines. Specific requirements may include ensuring compatibility with Cummins engines and adhering to recommended torque specifications for connections. Proper installation is key to achieving optimal performance and reliability.

Maintenance and Troubleshooting

Routine maintenance of the Turbocharger Oil Drain Connection involves regular inspection intervals to check for signs of wear or damage. Cleaning procedures may be necessary to remove any buildup that could impede function. Common troubleshooting steps for potential issues, such as leaks or blockages, involve checking connections and ensuring that the drain path is clear.

Common Issues and Solutions

Frequent problems associated with the Turbocharger Oil Drain Connection can include leaks or blockages. Solutions may involve tightening connections, cleaning the drain path, or replacing damaged components. Preventive measures include regular maintenance checks and ensuring that the system is free from contaminants.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its wide range of diesel engines and related components. With a history of innovation and quality, Cummins products are designed to meet the demanding requirements of heavy-duty applications, providing reliable performance and durability 3.

Role of Part 5306012 Turbocharger Oil Drain Connection in Engine Systems

The 5306012 Turbocharger Oil Drain Connection is an essential component in the efficient operation of engine systems, particularly in turbocharged engines. This component is integral to the management of oil within the turbocharger system, ensuring optimal performance and longevity of the turbocharger.

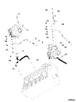

Integration with Turbocharger Plumbing

In the context of turbocharger plumbing, the 5306012 Turbocharger Oil Drain Connection serves as a vital junction. It facilitates the drainage of oil from the turbocharger, which is necessary to prevent oil buildup and contamination. This drainage is part of a closed-loop system where oil is circulated to lubricate and cool the turbocharger’s moving parts. The drain connection ensures that any excess or contaminated oil is efficiently removed from the system, maintaining the integrity of the oil supply and enhancing the turbocharger’s efficiency.

Functionality in Turbocharger Systems

Within the turbocharger itself, the 5306012 connection plays a key role in the oil management subsystem. Turbochargers rely on a continuous supply of oil for lubrication of the turbine and compressor bearings, as well as for cooling the turbine housing. The oil drain connection is strategically positioned to allow for the regular removal of used oil, which may contain particulates or have degraded over time. This regular drainage helps in maintaining the oil’s viscosity and cleanliness, which are vital for the turbocharger’s smooth operation.

Contribution to Overall Engine Efficiency

The efficient operation of the 5306012 Turbocharger Oil Drain Connection directly contributes to the overall efficiency of the engine. By ensuring that the turbocharger is properly lubricated and cooled, and that the oil system is free from contaminants, this component helps in maintaining the turbocharger’s performance. This, in turn, allows the engine to operate more efficiently, with improved power output and reduced wear on engine components.

Conclusion

In summary, the 5306012 Turbocharger Oil Drain Connection is a key element in the maintenance and operation of turbocharged engine systems. Its role in oil management within the turbocharger and its integration with turbocharger plumbing are essential for the sustained performance and reliability of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.