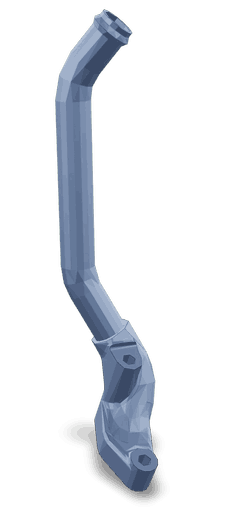

5307797

Turbocharger Oil Drain Connection

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbocharger Oil Drain Connection, identified by part number 5307797 and manufactured by Cummins, is a component integral to the turbocharger system of heavy-duty truck engines. Its role is to facilitate the efficient removal of used oil from the turbocharger, thereby contributing to the maintenance of engine efficiency and longevity.

Basic Concepts of Turbocharger Oil Drain Connection

Turbocharger systems operate by using exhaust gases to spin a turbine, which in turn drives a compressor to increase the amount of air entering the engine. This process enhances engine performance by allowing for more fuel to be burned, thus generating more power. The oil drain connection is a vital part of this system, as it allows for the removal of used oil that has lubricated the turbocharger’s moving parts. By ensuring that old oil is efficiently drained, the oil drain connection helps maintain the turbocharger’s optimal performance and prevents the buildup of contaminants that could impair its function 1.

Purpose of the Turbocharger Oil Drain Connection

The Turbocharger Oil Drain Connection is designed to play a specific role in the operation of heavy-duty trucks. It ensures that the turbocharger system operates efficiently by allowing for the regular removal of used oil. This process is important for maintaining the turbocharger’s performance and reliability, as it prevents the accumulation of debris and contaminants that could otherwise lead to decreased efficiency or failure of the turbocharger.

Key Features

The Turbocharger Oil Drain Connection is characterized by several key features that enhance its performance and durability. Its design is engineered to fit securely within the turbocharger system, ensuring a reliable seal that prevents oil leaks. The materials used in its construction are chosen for their ability to withstand the high temperatures and pressures present in the turbocharger environment. Additionally, the connection may include unique characteristics such as anti-corrosion coatings or reinforced seals to further enhance its longevity and performance.

Benefits

The advantages provided by the Turbocharger Oil Drain Connection include improved engine performance, extended turbocharger lifespan, and reduced maintenance requirements. By ensuring that the turbocharger is properly lubricated and free of contaminants, this component contributes to the overall efficiency of the engine. Furthermore, its design and construction help minimize the need for frequent maintenance, allowing for more reliable and uninterrupted operation of the vehicle.

Installation Process

Installing the Turbocharger Oil Drain Connection requires careful attention to detail to ensure correct fitting and function. The process involves preparing the turbocharger system by ensuring it is clean and free of debris. The connection should be aligned with the designated fitting point and secured according to the manufacturer’s instructions. Tools required may include wrenches and possibly a torque wrench to ensure the connection is tightened to the specified torque settings. Following these steps helps guarantee that the oil drain connection operates effectively within the turbocharger system.

Troubleshooting Common Issues

Common problems associated with the Turbocharger Oil Drain Connection can include leaks or blockages. To diagnose these issues, it is important to inspect the connection for signs of wear or damage, and to ensure that it is properly seated and tightened. If a leak is detected, the connection may need to be resealed or replaced. Blockages can often be resolved by cleaning the connection and ensuring that the oil pathways are clear. Regular inspection and maintenance can help prevent these issues from arising.

Maintenance Tips

To ensure the longevity and optimal performance of the Turbocharger Oil Drain Connection, regular maintenance practices are recommended. This includes periodic inspection for signs of wear or damage, cleaning the connection to remove any buildup, and following the manufacturer’s guidelines for when to consider replacement. Adhering to these maintenance tips helps maintain the efficiency of the turbocharger system and contributes to the overall reliability of the engine.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive industry, Cummins is committed to producing high-quality engine components and systems that meet the demanding requirements of heavy-duty applications. Their focus on innovation, quality, and customer satisfaction has established them as a trusted name in the field of engine technology.

Turbocharger Oil Drain Connection in Cummins Engines

The turbocharger oil drain connection, part number 5307797, is a critical component in the maintenance and operation of certain Cummins engines. This part is designed to facilitate the drainage of oil from the turbocharger, ensuring that the system remains clean and free from contaminants.

Application in Cummins Engines

QSB6.7 CM2350 B105

This part is specifically engineered to fit seamlessly within the engine architecture of the QSB6.7 CM2350 B105. The turbocharger oil drain connection ensures that oil is effectively drained from the turbocharger, preventing oil buildup that could lead to performance degradation or mechanical failure.

QSB6.7 CM2350

Similarly, in the QSB6.7 CM2350 engine, the turbocharger oil drain connection plays a pivotal role in maintaining the integrity of the turbocharger system. By ensuring that oil is properly drained, this part helps to prolong the life of the turbocharger and maintain optimal engine performance.

QSB6.7

For the QSB6.7 engine, the turbocharger oil drain connection is equally important. Its design allows for efficient oil drainage, which is crucial for the longevity and reliability of the turbocharger. This part is integral to the engine’s overall maintenance regimen.

CM2350

The turbocharger oil drain connection is also compatible with the CM2350 engine. Its precise fit and function ensure that oil is effectively managed within the turbocharger system, contributing to the engine’s efficiency and durability.

B105

In the B105 engine, this part is designed to integrate smoothly with the existing components, providing a reliable means of oil drainage from the turbocharger. This ensures that the turbocharger operates under optimal conditions, enhancing the engine’s performance and lifespan.

By ensuring that oil is properly drained from the turbocharger, the turbocharger oil drain connection helps maintain the efficiency and reliability of these Cummins engines. This part is a testament to Cummins’ commitment to providing high-quality components that enhance engine performance and longevity.

Role of Part 5307797 Turbocharger Oil Drain Connection in Engine Systems

The Turbocharger Oil Drain Connection, identified by part number 5307797, is an essential component in the efficient operation of turbocharged engine systems. This part is integral to the turbocharger plumbing system, ensuring that oil used for lubricating the turbocharger is effectively drained and managed.

In the context of turbocharger systems, the oil drain connection facilitates the removal of oil that has been used to lubricate the turbocharger’s moving parts. This oil, after circulating through the turbocharger, collects impurities and heat, which can adversely affect the turbocharger’s performance if not properly managed. The 5307797 connection plays a key role in this process by providing a reliable and secure point for the oil to be drained from the turbocharger.

Furthermore, in the broader scope of engine plumbing, the Turbocharger Oil Drain Connection is a vital link. It ensures that the oil drainage process is seamless, preventing any potential leaks or inefficiencies in the system. This is particularly important in high-performance engines where the turbocharger operates under extreme conditions, and the integrity of the oil management system is paramount.

The integration of the 5307797 connection within the turbocharger and engine plumbing systems underscores its importance in maintaining the overall health and efficiency of the engine. By ensuring effective oil drainage, this component contributes to the longevity and optimal performance of the turbocharger and, by extension, the entire engine system.

Conclusion

The Turbocharger Oil Drain Connection, part number 5307797, is a critical component in the maintenance and operation of turbocharged engine systems. Its role in facilitating the efficient removal of used oil from the turbocharger ensures the system remains clean, free from contaminants, and operates at optimal efficiency. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part, contributing to the overall reliability and performance of heavy-duty engines.

-

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.