This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

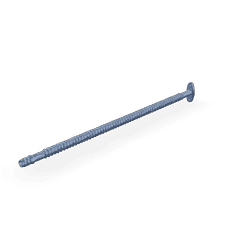

The Turbocharger Oil Drain Connection, identified by Part #5335324, is a component manufactured by Cummins, a leader in diesel engine technology. This part is integral to the maintenance and operation of heavy-duty truck engines, facilitating the efficient draining of oil from the turbocharger. Understanding its role and functionality is key to maintaining engine performance and longevity.

Basic Concepts

Turbochargers are devices that increase the efficiency and power output of diesel engines by compressing the air entering the engine. This compressed air allows for more fuel to be burned, resulting in enhanced performance. Oil plays a vital role in maintaining turbocharger performance by lubricating moving parts, reducing friction, and dissipating heat. The concept of an oil drain connection is crucial for the maintenance of turbochargers, allowing for the periodic removal of oil for inspection and replacement, which is necessary to ensure the turbocharger operates within optimal parameters 1.

Purpose of the Turbocharger Oil Drain Connection

The Turbocharger Oil Drain Connection serves a specific function in the operation of a truck’s engine. It enables the draining of oil from the turbocharger, which is a necessary procedure for maintenance and inspection. By providing a secure and efficient means to drain oil, this connection plays a role in ensuring that the turbocharger remains in good working condition, thereby contributing to the overall efficiency and reliability of the engine 2.

Key Features

The design and construction of the Turbocharger Oil Drain Connection are tailored to meet the demanding requirements of heavy-duty truck engines. Crafted from durable materials, it is built to withstand the high pressures and temperatures associated with turbocharger operation. Its connection type is designed for ease of use, allowing for straightforward oil drainage procedures. Unique attributes of this part may include corrosion-resistant coatings and precision-machined fittings, which enhance its functionality and durability 3.

Benefits

The Turbocharger Oil Drain Connection offers several advantages. It contributes to improved maintenance efficiency by simplifying the oil drainage process. This, in turn, can lead to enhanced turbocharger longevity, as regular oil changes are facilitated. Additionally, by ensuring the turbocharger operates with fresh, clean oil, the connection plays a role in maintaining overall engine performance, efficiency, and reliability 4.

Installation and Compatibility

Proper installation of the Turbocharger Oil Drain Connection is crucial for its effective operation. Guidelines for installation should be followed to ensure a secure and leak-free connection. Compatibility with various Cummins engine models is an important consideration, ensuring that the connection is suitable for the specific engine it is intended to service.

Troubleshooting and Maintenance

Common issues with Turbocharger Oil Drain Connections can include leaks, blockages, or corrosion. Diagnostic tips for identifying these problems may involve visual inspections and pressure tests. Maintenance practices, such as regular inspections and cleaning, are vital to ensure optimal performance and longevity of the connection. Emphasizing the importance of these practices can help prevent more serious issues down the line.

Cummins Overview

Cummins Inc. has a long-standing reputation in the diesel engine and components industry. Founded with a commitment to quality and innovation, Cummins has consistently delivered reliable and high-performance automotive parts. Their dedication to excellence is evident in the design and manufacturing of components like the Turbocharger Oil Drain Connection, underscoring their role as a trusted provider in the industry.

Application in Cummins Engines

4B3.9 Engines

The 4B3.9 engine series by Cummins is known for its robust performance and reliability. The turbocharger oil drain connection, part 5335324, is integral to the engine’s lubrication system, ensuring that the turbocharger is properly lubricated and that any excess oil is effectively drained. This part is engineered to withstand the high-stress conditions within the engine, providing a reliable connection that minimizes the risk of oil leaks and ensures consistent performance.

Other Cummins Engines

While the specific application of part 5335324 in the 4B3.9 engine is highlighted, it is also compatible with other Cummins engines that utilize similar turbocharger systems. The design and functionality of this part are standardized across various Cummins engine models, ensuring that it fits seamlessly into the engine’s lubrication system. This compatibility allows for easier maintenance and repair, as technicians can use the same part across different engine types, reducing inventory needs and simplifying the repair process.

The turbocharger oil drain connection is a testament to Cummins’ commitment to quality and reliability, providing a critical function in the engine’s overall performance and longevity.

Role of Part 5335324 Turbocharger Oil Drain Connection in Engine Systems

The Turbocharger Oil Drain Connection is an essential component in the maintenance and operation of turbocharger systems within various engine setups. This part facilitates the drainage of oil from the turbocharger, ensuring that the lubrication system remains efficient and that the turbocharger operates within optimal parameters.

Integration with Turbocharger Systems

In turbocharger systems, the oil drain connection is strategically positioned to allow for the periodic removal of oil that has been used to lubricate the turbocharger’s moving parts. This process is vital for maintaining the integrity of the lubrication system, as it prevents the buildup of contaminants and degradation products that can form in the oil over time. The drained oil is typically routed back to the engine’s sump or a dedicated oil reservoir, where it can be filtered and recirculated, or disposed of according to maintenance schedules.

Interaction with Plumbing Components

The effectiveness of the Turbocharger Oil Drain Connection is closely tied to the engine’s plumbing system. The oil drain connection must be correctly integrated with the engine’s oil lines to ensure a seamless flow of oil to and from the turbocharger. This integration involves precise fitting and sealing to prevent leaks, which could lead to oil loss and potential engine damage. The connection also plays a role in the overall pressure management within the lubrication system, contributing to the stable operation of the turbocharger under varying engine loads.

Maintenance and Operational Considerations

Regular maintenance of the oil drain connection is necessary to ensure its continued functionality. This includes checking for signs of wear or corrosion, ensuring that seals are intact, and verifying that the connection points are secure. In operational terms, the drain connection allows for the monitoring of oil condition, providing insights into the health of the turbocharger and the engine as a whole. By facilitating the removal of used oil, it supports the turbocharger’s efficiency and longevity, directly impacting the engine’s performance and reliability.

Conclusion

The Turbocharger Oil Drain Connection, part number 5335324, is a critical component in the maintenance and operation of heavy-duty truck engines. Its role in facilitating the efficient drainage of oil from the turbocharger ensures that the engine operates within optimal parameters, contributing to its overall performance, efficiency, and reliability. Regular maintenance and proper installation of this part are essential to ensure its continued functionality and the longevity of the turbocharger and engine as a whole.

-

SAE International’s Dictionary for Automotive Engineers, John F Kershaw, SAE International, 2023

↩ -

Fundamentals of Vehicle Dynamics and Modelling, Bruce P. Minaker, John Wiley Sons, 2019

↩ -

Heavyduty Electric Vehicles: From Concept to Reality, Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Elsevier, 2021

↩ -

How to Rebuild Any Automotive Engine, Barry Kluczyk, CarTech, 2008

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.