This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

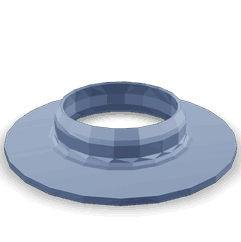

The Valve Spring Guide, identified by part number 163061, is a component manufactured by Cummins, a well-established name in the commercial truck industry. This guide plays a significant role in the engine’s operation by ensuring the proper function of the valve spring. Its design and material are tailored to withstand the demanding conditions within an engine, contributing to the overall efficiency and reliability of the engine system 1.

Function and Operation

The Valve Spring Guide operates by providing a stable pathway for the valve spring within the engine. It interacts closely with the valve spring, valve stem, and other valve train components. By maintaining the alignment and integrity of the valve spring, the guide helps in ensuring that the valve opens and closes precisely as intended. This precise operation is vital for the engine’s performance, as it directly affects the timing and efficiency of the air and fuel mixture’s combustion 2.

Key Features

This Cummins part is characterized by its robust design and high-quality materials, which are selected to endure the high temperatures and pressures present in engine environments. Its construction often includes heat-treated steel or other durable alloys, which enhance its resistance to wear and deformation. The guide’s precise dimensions and smooth surface finish are critical for minimizing friction and ensuring consistent valve spring performance 3.

Benefits

Incorporating the Valve Spring Guide into an engine system offers several advantages. It contributes to improved engine efficiency by ensuring that the valve spring operates within its designed parameters. This results in reduced wear on valve components, leading to longer intervals between maintenance and repairs. Additionally, the guide enhances overall engine performance by supporting the valve train’s precise operation, which is crucial for optimal combustion and power output.

Installation and Maintenance

Proper installation of the Valve Spring Guide is crucial for its effective function. It should be securely positioned within the engine block or cylinder head, ensuring it is aligned correctly with the valve spring and other components. Regular maintenance practices, such as inspecting for signs of wear or damage and ensuring it remains free of debris, are recommended to maintain optimal performance. Following the manufacturer’s guidelines for maintenance intervals and procedures will help in preserving the guide’s integrity and the engine’s efficiency.

Troubleshooting Common Issues

Typical problems associated with Valve Spring Guides may include wear, deformation, or misalignment. These issues can lead to valve spring failure, affecting engine performance. Diagnostic procedures involve visual inspection for physical damage, checking the alignment with other valve train components, and assessing the overall condition of the guide. Potential solutions may range from cleaning and realigning the guide to replacing it if significant wear or damage is detected.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable, high-performance engines and components. Their product range is designed to meet the demanding requirements of various applications, ensuring durability, efficiency, and performance.

Role of Part 163061 Valve Spring Guide in Engine Systems

The Valve Spring Guide (163061) is an essential component in the operation of the cylinder head within an engine system. It is specifically designed to maintain the alignment and stability of the valve spring, ensuring that the valve operates smoothly and efficiently.

When the engine is running, this part works in conjunction with the valve spring to control the opening and closing of the valves. It ensures that the spring remains centered over the valve stem, preventing any lateral movement that could lead to wear or damage. This alignment is vital for the consistent and precise operation of the valve train.

In the cylinder head, the Valve Spring Guide interacts with several other components. It sits above the valve stem and below the valve spring, providing a stable pathway for the spring to follow as the valve moves. This setup helps in maintaining the integrity of the valve seal, ensuring that the combustion chamber remains properly sealed during engine operation.

The guide also plays a role in reducing friction and wear on the valve stem. By keeping the spring in the correct position, it minimizes the contact between the spring and other components, which can otherwise lead to increased wear and potential failure.

Overall, the Valve Spring Guide (163061) is a key element in the valve train system, contributing to the reliable and efficient performance of the engine by ensuring proper valve spring alignment and function.

Conclusion

The Valve Spring Guide (163061) by Cummins is a critical component in ensuring the efficient and reliable operation of engine systems. Its role in maintaining valve spring alignment and reducing friction contributes significantly to engine performance and longevity. Proper installation, regular maintenance, and timely troubleshooting are essential practices to maximize the benefits of this part.

-

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ -

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.