This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Valve Spring 2831473 by Cummins is a component designed to ensure the proper operation of valves within commercial truck engines. Valve springs are integral to the valve train system, facilitating the opening and closing of engine valves at precise moments. Cummins, a renowned manufacturer in the commercial truck industry, produces this valve spring, leveraging its expertise to enhance engine performance and reliability 1.

Basic Concepts of Valve Springs

Valve springs are coil springs positioned above the valves in an engine. Their primary function is to keep the valves in contact with their respective valve seats when the engine is not in operation and to control the valve’s movement during engine operation. When the camshaft lobe lifts the valve, the valve spring compresses, allowing the valve to open. Once the camshaft lobe moves away, the spring expands, pulling the valve back to its seat, ensuring a tight seal. This mechanism is vital for maintaining the engine’s efficiency and performance 2.

Role of Valve Spring 2831473 in Truck Operation

The Valve Spring 2831473 plays a specific role in the engine’s valve train system by ensuring that the valves open and close at the correct times and with the appropriate force. This spring is engineered to handle the high stresses and temperatures encountered in commercial truck engines, contributing to consistent valve operation and engine performance. Its design helps in maintaining valve seat integrity, preventing issues such as valve float at high engine speeds, which can lead to decreased performance and potential engine damage 3.

Key Features of Valve Spring 2831473

The Valve Spring 2831473 is constructed with high-quality materials, typically including heat-treated alloy steel, to withstand the demanding conditions within a commercial truck engine. The spring rate, or the force required to compress the spring a certain distance, is carefully calibrated to match the specific requirements of the engine it serves. Additionally, the spring may feature unique design elements such as dual springs or retainers to enhance performance and durability under high-stress conditions 4.

Benefits of Using Valve Spring 2831473

Utilizing the Valve Spring 2831473 offers several advantages. Its robust design and material composition contribute to improved engine reliability, ensuring consistent valve operation even under strenuous conditions. Enhanced performance is another benefit, as the spring’s precise engineering allows for optimal valve timing and sealing. Over time, the durability and efficiency of this valve spring can lead to potential cost savings by reducing the need for frequent replacements and repairs 5.

Troubleshooting Common Issues with Valve Springs

Common issues with valve springs, such as valve float or spring failure, can significantly impact engine performance. Valve float occurs when the spring cannot keep the valve closed at high engine speeds, leading to incomplete combustion. Spring failure can result from fatigue or excessive heat. Regular maintenance, including inspection for signs of wear or damage, is crucial for identifying potential issues early. Addressing these problems promptly can prevent more severe engine damage 6.

Maintenance Tips for Valve Spring 2831473

To ensure the longevity and performance of the Valve Spring 2831473, regular maintenance is recommended. Inspection intervals should be observed according to the manufacturer’s guidelines, looking for signs of wear, corrosion, or damage. Best practices include cleaning the spring and its components to remove any debris that could affect performance and ensuring that all related components, such as retainers and keepers, are in good condition. Adhering to these maintenance tips can help maintain the spring’s effectiveness and extend its service life 7.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company’s commitment to advancing technology and meeting the needs of its customers underscores its position as a leader in engine manufacturing and component production, including high-quality valve springs like the 2831473 8.

Valve Spring Part 2831473 Compatibility with Cummins Engines

The Valve Spring part number 2831473, manufactured by Cummins, is a critical component in ensuring the proper operation of the engine’s valve train. This part is designed to fit seamlessly within various Cummins engine models, providing the necessary tension and resilience required for the valves to open and close efficiently.

ISBE CM800 Engine Group

The ISBE CM800 engine, part of the Cummins ISBE series, is a high-performance, heavy-duty diesel engine. The Valve Spring part 2831473 is specifically engineered to meet the stringent demands of this engine group. Its design ensures optimal performance under heavy loads and high-stress conditions, contributing to the engine’s reliability and longevity.

The ISBE CM800 engine is known for its robust construction and superior fuel efficiency, making it a preferred choice in various industrial and commercial applications. The Valve Spring part 2831473 plays a pivotal role in maintaining the engine’s efficiency by ensuring that the valves operate smoothly and precisely, which is crucial for the engine’s overall performance.

In the ISBE CM800 engine group, the Valve Spring part 2831473 is a critical component that supports the engine’s high-stress environment. Its compatibility with this engine group underscores its importance in maintaining the engine’s operational integrity and performance 9.

Role of Part 2831473 Valve Spring in Engine Systems

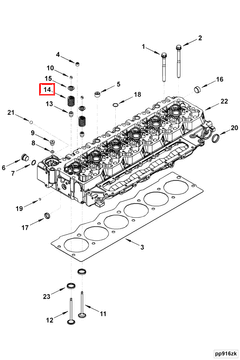

The part 2831473 Valve Spring is an essential component within the engine’s valve train system, ensuring the proper operation of the valve mechanism. It is strategically positioned between the valve keeper and the valve spring seat on the cylinder head.

When the engine operates, the camshaft opens the valves by pushing against the valve stem. The valve spring, specifically part 2831473, plays a significant role here. It maintains the valve’s closed position when the camshaft lobe is not actively opening it. This ensures that the valve returns to its seat promptly and securely after being opened, preventing any potential valve float at high engine speeds. Valve float can lead to decreased engine performance and potential damage.

Moreover, the valve spring’s design and material properties are tailored to withstand the high temperatures and pressures within the cylinder head. It must provide consistent force throughout the engine’s operational range to ensure reliable valve operation. The spring’s ability to maintain its structural integrity under these conditions is vital for the engine’s overall efficiency and durability.

In summary, part 2831473 Valve Spring is integral to the engine’s valve train system, ensuring that valves open and close with precision, contributing to the engine’s performance and longevity 10.

Conclusion

The Valve Spring 2831473 by Cummins is a critical component in the operation of commercial truck engines, ensuring precise valve timing and sealing. Its robust design, compatibility with various Cummins engine models, and the benefits it offers in terms of engine reliability and performance make it a valuable part for maintaining the efficiency and durability of truck engines. Regular maintenance and prompt troubleshooting of common issues are essential for maximizing the lifespan and effectiveness of this valve spring.

-

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Brown Jr, A. (2010). Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences.

↩ -

Hilgers, M. (2023). Chassis and Axles. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). General Information, Bulletin Number 4021558, Operation and Maintenance Manual.

↩ -

Cummins Inc. (n.d.). General Information, Bulletin Number 4021558, Operation and Maintenance Manual.

↩ -

Cummins Inc. (n.d.). General Information, Bulletin Number 4021558, Operation and Maintenance Manual.

↩ -

Cummins Inc. (n.d.). General Information, Bulletin Number 4021558, Operation and Maintenance Manual.

↩ -

Cummins Inc. (n.d.). General Information, Bulletin Number 4021558, Operation and Maintenance Manual.

↩ -

Cummins Inc. (n.d.). General Information, Bulletin Number 4021558, Operation and Maintenance Manual.

↩ -

Cummins Inc. (n.d.). General Information, Bulletin Number 4021558, Operation and Maintenance Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.