This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

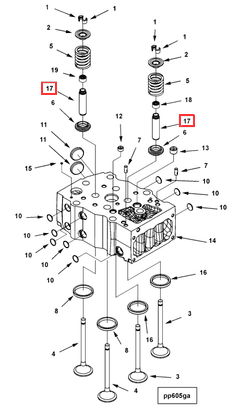

The Valve Stem Guide 2881436, a component designed by Cummins for use in commercial truck engines, facilitates the smooth operation of the engine’s valve system. By ensuring precise valve movement, this part contributes to the overall efficiency and performance of the engine.

Basic Concepts of Valve Stem Guides

A Valve Stem Guide is a cylindrical component that supports and directs the movement of the valve stem within the engine. It plays a role in maintaining the alignment and stability of the valve as it opens and closes. This alignment is important for the engine’s performance, as it ensures that the valve seats properly against the cylinder head, allowing for efficient combustion and exhaust processes 1.

Purpose of the Valve Stem Guide 2881436

The Valve Stem Guide 2881436 is specifically engineered to enhance the operation of the valve system in Cummins engines. It contributes to the precise movement of the valve, which is vital for maintaining engine efficiency. By providing a smooth path for the valve stem, it helps reduce wear and tear on the valve and other components, thereby supporting the engine’s overall performance and longevity.

Key Features

The Valve Stem Guide 2881436 is characterized by its durable material composition, which is designed to withstand the high temperatures and pressures within the engine. Its design includes precise dimensions to ensure a snug fit around the valve stem, minimizing the risk of misalignment. Additionally, the guide may feature unique attributes such as a coated surface to reduce friction and enhance durability.

Benefits of Using Valve Stem Guide 2881436

Incorporating the Valve Stem Guide 2881436 into truck engines offers several advantages. It contributes to improved engine performance by ensuring smooth and precise valve operation. The guide’s durable construction enhances the engine’s reliability and longevity, reducing the need for frequent maintenance or replacements. Furthermore, its design helps maintain optimal engine efficiency, which can lead to better fuel economy and reduced emissions 2.

Installation and Maintenance

Proper installation of the Valve Stem Guide 2881436 is crucial for its effective operation. It should be carefully aligned with the valve stem and securely placed within the cylinder head. Regular maintenance, including inspection for wear or damage, is recommended to ensure the guide continues to function optimally. Cleaning the guide and ensuring it is free from debris can also contribute to its longevity and performance.

Troubleshooting Common Issues

Typical problems associated with Valve Stem Guides may include wear, misalignment, or damage due to high temperatures or pressures. Symptoms of these issues can include engine misfires, reduced performance, or unusual noises from the engine. Addressing these problems may involve inspecting the guide for signs of wear, ensuring it is properly aligned, or replacing it if damage is detected.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to excellence is reflected in its wide range of products, which are designed to meet the demanding requirements of commercial applications 3.

Interaction with the Cylinder Head

The Valve Stem Guide is housed within the cylinder head, where it supports the valve stem. As the camshaft actuates the valve through the camshaft cover, the guide ensures that the valve stem moves vertically without deviation. This precise movement is necessary for the valve to seal properly against the cylinder head, allowing for optimal combustion efficiency.

Coordination with the Camshaft and Camshaft Cover

The camshaft, driven by the engine’s timing belt or chain, interacts with the valve through the camshaft cover. The Valve Stem Guide plays a supporting role here by ensuring that the valve stem’s motion is consistent and aligned. This alignment is vital for the camshaft to effectively open and close the valve at the correct times, which is essential for the engine’s performance.

Impact on the Connecting Rod and Piston

Indirectly, the Valve Stem Guide affects the connecting rod and piston assembly. Proper valve operation, facilitated by the guide, ensures that the air-fuel mixture is admitted into the cylinder at the right moment. This timing is crucial for the piston to compress the mixture effectively before ignition. Any misalignment or wear in the valve stem guide could lead to inefficient combustion, affecting the overall performance of the connecting rod and piston.

Relationship with the Injector

In fuel-injected engines, the injector plays a role in delivering the precise amount of fuel into the cylinder. The Valve Stem Guide, by ensuring proper valve operation, helps maintain the correct timing for fuel admission. This timing is essential for the injector to deliver fuel efficiently, contributing to the engine’s overall performance and fuel economy.

Supporting Role in Wiring and Retainer Bracket

Although not directly related to the electrical components, the Valve Stem Guide’s role in maintaining valve integrity indirectly supports the engine’s electrical systems. Proper valve operation ensures that the engine runs smoothly, reducing the strain on electrical components such as sensors and the wiring retainer bracket. This, in turn, contributes to the longevity and reliability of the engine’s electrical systems.

Conclusion

The Valve Stem Guide 2881436 is a foundational component that supports the intricate dance of parts within the engine. Its role in maintaining valve stem alignment and movement is important for the efficient operation of the camshaft, cylinder head, connecting rod and piston, injector, and even the electrical components.

-

Denton, T., & Pells, H. (2022). Automotive Technician Training Theory. Routledge.

↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩ -

Lakshminarayanan, P. A., & Aghav, Y. V. (2010). Modelling Diesel Combustion. Springer Science.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.