This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3005807 Float Valve is a component designed for use in commercial trucks. It serves a specific function within the vehicle’s fluid management system, contributing to the overall efficiency and reliability of the truck’s operation. Understanding its purpose and significance can help in maintaining the vehicle’s performance and longevity.

Basic Concepts of Float Valves

A float valve is a mechanical device used to control the flow of liquids within a system. It operates using a float, which rises or falls with the liquid level. As the liquid level changes, the float moves, opening or closing the valve to maintain a consistent level. Float valves are commonly used in various fluid management applications, including fuel and coolant systems, to ensure that the liquid levels remain within the desired range 1.

Purpose of the 3005807 Float Valve

This Cummins part plays a role in the truck’s fluid system by regulating the level of fluid, whether it be fuel or coolant. It ensures that the system maintains the appropriate fluid level, which is vital for the efficient operation of the truck. By controlling the fluid level, the valve helps prevent overflow and underflow, which could lead to system inefficiencies or damage.

Key Features

The 3005807 Float Valve is characterized by its robust design and the quality materials used in its construction. It is engineered to withstand the demanding conditions of heavy-duty truck applications. The valve’s design includes a float mechanism that responds to changes in fluid level, and it is constructed from materials that offer durability and resistance to corrosion. These features contribute to the valve’s reliable performance in maintaining fluid levels.

Benefits

This Cummins part offers several advantages. It provides efficient maintenance of fluid levels, which is crucial for the consistent operation of the truck’s systems. The valve’s durable construction ensures longevity, even in the harsh environments typical of commercial truck use. Its reliable performance contributes to the overall efficiency and reliability of the truck’s fluid management system.

Installation Considerations

When installing the 3005807 Float Valve, it is important to follow guidelines to ensure proper function. This includes ensuring that the valve is correctly positioned within the system and that all connections are secure. Preparatory steps may involve cleaning the installation area and checking that all components are compatible with the valve. The use of appropriate tools is recommended to facilitate a smooth installation process.

Troubleshooting Common Issues

Float valves, including the 3005807, may encounter issues such as sticking or improper level control. These problems can often be traced to debris within the system, wear on the valve components, or incorrect installation. Addressing these issues may involve cleaning the valve, replacing worn parts, or readjusting the valve’s position within the system.

Maintenance Tips

To ensure the longevity and optimal performance of the 3005807 Float Valve, routine maintenance is recommended. This includes regular inspection for signs of wear or damage, cleaning the valve to remove any buildup that could affect its operation, and ensuring that all connections remain tight and secure. Adhering to a maintenance schedule can help prevent issues and extend the service life of the valve.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes a variety of components and systems designed to enhance the performance and reliability of commercial vehicles.

Cummins Float Valve 3005807 Compatibility

The Cummins Float Valve part number 3005807 is a component in the fuel management system of certain engines. This part is designed to ensure proper fuel delivery and management within the engine’s fuel system. Below is a detailed description of how this float valve fits with the specified Cummins engines.

K38 Engine

The Cummins K38 engine is a robust and reliable power unit, often utilized in various industrial and commercial applications. The float valve part number 3005807 is integral to the K38 engine’s fuel system, where it plays a pivotal role in maintaining the correct fuel level within the carburetor or fuel injection system. This ensures that the engine receives a consistent and appropriate fuel supply, which is essential for optimal performance and efficiency.

K50 Engine

Similarly, the Cummins K50 engine benefits from the precise functionality of the float valve part number 3005807. This engine is also widely used in industrial and commercial settings, and the float valve is a key component in its fuel management system. By regulating the fuel level, the float valve helps maintain the engine’s performance and efficiency, ensuring that it operates smoothly and reliably under various conditions.

Grouping of Engines

Both the K38 and K50 engines are part of Cummins’ lineup of industrial and commercial engines, known for their durability and performance. The float valve part number 3005807 is compatible with these engines, providing a reliable solution for maintaining the fuel system’s integrity. This compatibility ensures that users can maintain and repair these engines with confidence, knowing that the float valve is a well-suited component for their specific needs.

Role of Part 3005807 Float Valve in Engine Systems

In the orchestration of engine systems, the 3005807 Float Valve assumes a significant role, particularly in the management and regulation of fuel levels. This component is integral to the operation of the float tank and the fuel transfer tank, ensuring a consistent and reliable fuel supply to the engine.

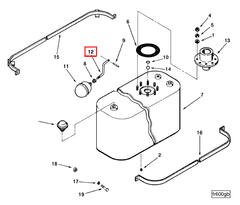

Integration with the Float Tank

The float tank is a reservoir designed to maintain a stable fuel level, which is essential for the proper functioning of the engine. The 3005807 Float Valve is positioned within this tank, where it monitors the fuel level. As the fuel level fluctuates, the float valve responds by either allowing more fuel to enter the tank or shutting off the fuel supply, thereby maintaining an optimal fuel level. This balance is vital for the engine’s performance, as it ensures that there is neither an excess nor a deficiency of fuel, which could lead to engine malfunctions or inefficiencies.

Coordination with the Fuel Transfer Tank

The fuel transfer tank serves as an intermediary storage unit, facilitating the movement of fuel from the main storage to the float tank. The 3005807 Float Valve plays a pivotal role in this process by regulating the flow of fuel into the float tank. When the float valve detects a low fuel level in the float tank, it opens to allow fuel from the transfer tank to replenish the supply. Conversely, when the desired fuel level is reached, the float valve closes, preventing overfilling. This precise control is essential for the seamless operation of the fuel system, ensuring that the engine receives a consistent fuel supply under varying operational conditions.

Overall System Harmony

The effective operation of the 3005807 Float Valve within these components is a testament to the intricate design of engine fuel systems. By maintaining a stable fuel level in the float tank and regulating the flow from the fuel transfer tank, the float valve contributes to the overall efficiency and reliability of the engine. Its role is a clear example of how individual components, when functioning in unison, can significantly enhance the performance and longevity of engine systems.

Conclusion

The Cummins 3005807 Float Valve is a critical component in the fluid management system of commercial trucks, ensuring the efficient operation of the vehicle by maintaining appropriate fluid levels. Its robust design, durable construction, and reliable performance make it a valuable asset in the maintenance and longevity of truck systems. Proper installation, regular maintenance, and troubleshooting of common issues are essential to maximize the benefits of this Cummins part.

-

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing Limited.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.