This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

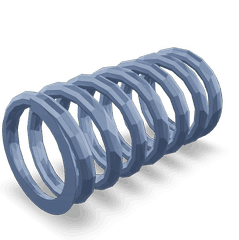

The Valve Spring Assembly 3005959, manufactured by Cummins, is a vital component in the operation of commercial trucks. Cummins, a well-established name in the automotive industry, is renowned for its high-quality engine components. This part plays a significant role in ensuring the efficient and reliable operation of truck engines.

Basic Concepts of Valve Spring Assembly

Valve spring assemblies are fundamental to the operation of an engine’s valve train. Their primary function is to maintain proper valve operation by ensuring that the valves open and close at the correct times. This is achieved through the spring’s ability to apply consistent pressure on the valve, allowing it to return to its closed position after being opened by the camshaft. Proper valve timing and sealing are crucial for engine performance, as they directly affect the intake and exhaust processes. A well-functioning valve spring assembly contributes to efficient combustion and overall engine efficiency 1.

Role of the 3005959 Valve Spring Assembly in Truck Operation

This Cummins part is integral to the performance and efficiency of a truck’s engine. It ensures that the valves operate correctly under various driving conditions, which is vital for maintaining engine performance. By providing consistent pressure on the valves, this assembly helps in achieving precise valve timing, which is essential for optimal engine operation. Its role becomes particularly significant under high-stress conditions, such as heavy loads or high speeds, where the demands on the engine are greater.

Key Features of the 3005959 Valve Spring Assembly

This part is designed with specific features that enhance its durability, performance, and reliability. It is constructed using high-quality materials that can withstand the rigors of commercial truck operation. The assembly’s design includes elements that improve its resilience and efficiency, such as advanced spring winding techniques and precise manufacturing tolerances. These features contribute to its longevity and consistent performance, setting it apart from other valve spring assemblies.

Benefits of Using the 3005959 Valve Spring Assembly

Utilizing this part offers several advantages. It contributes to improved engine efficiency by ensuring precise valve operation, which leads to better combustion and fuel economy. The assembly’s robust design reduces the need for frequent maintenance, which can result in cost savings for fleet operators. Additionally, its reliable performance enhances overall engine efficiency, leading to increased uptime and reduced downtime for commercial trucks.

Troubleshooting and Maintenance Tips

Identifying common issues with valve spring assemblies, such as valve train noise or decreased engine performance, is important for maintaining engine health. Regular inspections and maintenance can help in detecting early signs of wear or failure. Routine practices, such as checking for proper valve clearance and ensuring the springs are free from damage, can contribute to the longevity and optimal performance of the Valve Spring Assembly 3005959. Timely replacement of worn components is also recommended to prevent engine damage 2.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its innovative engine solutions and commitment to quality. With a rich history of providing reliable and high-performance engine components, Cummins has established a strong reputation among fleet operators. The company’s dedication to innovation, quality, and customer satisfaction is evident in its product offerings, including the Valve Spring Assembly 3005959. Cummins continues to be a trusted name in the industry, delivering products that meet the demanding requirements of commercial truck operations.

Valve Spring Assembly (Part 3005959) Compatibility with Cummins Engines

The Valve Spring Assembly (Part 3005959) manufactured by Cummins is a critical component in ensuring the proper operation of the valve train in various Cummins engines. This part is designed to fit seamlessly within the engine architecture, providing the necessary spring force to keep the engine valves closed during the compression and power strokes.

N14 Mechanical Engine

In the N14 Mechanical engine, the Valve Spring Assembly (Part 3005959) plays a pivotal role in maintaining the integrity of the valve train system. This engine, known for its robust design and reliability, relies on the precise function of the valve springs to ensure optimal performance and longevity. The assembly is engineered to withstand the high stresses and temperatures inherent in diesel engine operations, ensuring consistent valve closure and reducing the risk of valve float at high RPMs.

NH/NT 855 Engines

The NH/NT 855 engines also benefit from the use of the Valve Spring Assembly (Part 3005959). These engines, which are part of Cummins’ lineup of heavy-duty diesel engines, are designed for durability and efficiency. The valve spring assembly in these engines is crucial for maintaining the precise valve timing necessary for smooth engine operation. The assembly’s design ensures that the valves open and close at the correct intervals, contributing to the engine’s overall performance and fuel efficiency.

By integrating the Valve Spring Assembly (Part 3005959) into these engines, Cummins ensures that the valve train operates smoothly and reliably, enhancing the engine’s performance and extending its service life.

Role of Part 3005959 Valve Spring Assembly in Engine Systems

The Valve Spring Assembly (part 3005959) is integral to the operation of several key engine components, ensuring efficient and reliable performance.

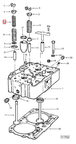

Interaction with the Cylinder Head

In the cylinder head, the Valve Spring Assembly maintains the proper sealing of the valves against the valve seats. This ensures that the combustion process is contained within the cylinder, maximizing engine efficiency and power output. The spring’s design allows it to withstand the high temperatures and pressures generated during combustion, contributing to the durability of the cylinder head.

Contribution to Exhaust Brake Systems

When integrated with an Exhaust Brake Kit, such as those for the NTC350 and NTC400, the Valve Spring Assembly plays a significant role in managing engine braking forces. By keeping the valves seated under the increased pressure from the exhaust brake, the assembly helps in achieving effective engine retardation, which is essential for safe vehicle operation, especially in heavy-duty applications.

Enhancing Performance Parts

In conjunction with performance parts, the Valve Spring Assembly is often upgraded to handle the increased stress from higher engine RPMs and greater valve lift. This enhancement ensures that the valves open and close at the precise moments required for optimal performance, directly influencing the engine’s power output and responsiveness.

Supporting the Head Cylinder Assembly

Within the head cylinder assembly, the Valve Spring Assembly ensures that the valves return to their closed position after each combustion cycle. This consistent valve operation is vital for maintaining the engine’s overall performance and longevity, preventing issues such as valve float, which can occur at high RPMs.

Conclusion

In summary, the Valve Spring Assembly (part 3005959) is a fundamental component that interacts with various engine systems to ensure reliable and efficient operation. Its role in maintaining valve integrity and performance is indispensable across different engine configurations and applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.