This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3018307 Valve Brace is a component designed to enhance the performance and durability of heavy-duty truck engines. It plays a role in maintaining the structural integrity and operational efficiency of the engine under demanding conditions.

Basic Concepts of Valve Braces

A valve brace is a structural component within an engine that provides additional support to the valve train. It helps in maintaining the alignment and stability of the valves, which are essential for the engine’s combustion process 1. By reinforcing the valve train, a valve brace contributes to the engine’s overall performance and longevity, ensuring that the valves operate smoothly and efficiently even under high stress.

Purpose of the Cummins 3018307 Valve Brace

This Cummins part is specifically engineered to support the valve train in Cummins engines. It enhances engine stability and performance, particularly under high stress conditions. By providing additional support, it helps in reducing the wear and tear on the valve components, thereby contributing to the engine’s durability and efficiency.

Key Features

The 3018307 Valve Brace is constructed from high-quality materials, ensuring durability and reliability. Its design incorporates precise engineering to fit seamlessly within the engine’s architecture. Unique attributes of this valve brace include its robust construction and the precision with which it is manufactured, enhancing its functionality and effectiveness in supporting the valve train.

Benefits

The installation of this part offers several advantages. It contributes to improved engine longevity by reducing the stress on valve components. Enhanced engine performance is another benefit, as the brace helps maintain optimal valve operation. Additionally, fleet operators may experience cost savings due to reduced maintenance needs and extended engine life.

Installation Considerations

When installing the 3018307 Valve Brace, it is important to follow guidelines and best practices to ensure proper integration within the engine. Preparatory steps include ensuring the engine is clean and free of debris. The necessary tools for installation should be readily available. Common pitfalls to avoid include improper alignment and over-tightening, which can lead to damage or reduced effectiveness of the brace.

Troubleshooting and Maintenance

Identifying common issues related to the 3018307 Valve Brace involves monitoring the engine’s performance and listening for unusual noises that may indicate valve train problems. Diagnostic procedures should be conducted regularly to assess the condition of the brace and its effectiveness. Maintenance practices include periodic inspections and cleaning to ensure optimal performance and longevity of the valve brace.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the heavy-duty truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s product range includes engines and components that are designed to meet the demanding requirements of heavy-duty applications 2.

Role of Part 3018307 Valve Brace in Engine Systems

The 3018307 Valve Brace is an integral component in the structural integrity and operational efficiency of various engine systems. Its application spans across multiple components, ensuring stability and precise functionality.

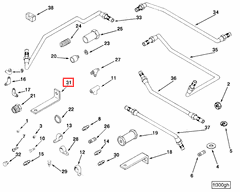

Check Valve Mounting

In check valve systems, the 3018307 Valve Brace provides essential support, maintaining the valve’s position and alignment. This ensures unidirectional flow, preventing backflow which could lead to system inefficiencies or damage.

Fuel Supply Tubing Mounting

When mounted to fuel supply tubing, the Valve Brace enhances the tubing’s resistance to vibrations and mechanical stresses. This support is vital for maintaining the integrity of the fuel supply line, ensuring a consistent and reliable fuel delivery to the engine.

Fuel Tubing and Plumbing

In fuel tubing and overall engine plumbing, the 3018307 Valve Brace plays a significant role in securing connections and joints. It helps in reducing the risk of leaks and disconnections, which are common issues in dynamic engine environments.

FS Tubing Mounting

For FS (Fuel Supply) tubing, the Valve Brace is employed to reinforce the tubing against the pressures and movements inherent in engine operation. This reinforcement is key to preserving the structural integrity of the fuel supply pathway.

Mounting FS Tubing

In scenarios where FS tubing requires additional mounting, the 3018307 Valve Brace offers the necessary support. It ensures that the tubing remains securely in place, contributing to the overall stability and reliability of the fuel system.

By integrating the 3018307 Valve Brace into these components, engine systems benefit from enhanced durability, reduced maintenance needs, and improved operational performance.

Conclusion

The Cummins 3018307 Valve Brace is a critical component for enhancing the performance and durability of heavy-duty truck engines. Its role in supporting the valve train and various engine components ensures optimal engine operation, longevity, and reliability. Proper installation, maintenance, and troubleshooting are essential for maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.