This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3019794 Check Valve is a component designed for use in commercial truck systems. Its purpose is to regulate the flow of fluid within the system, ensuring that it moves in the intended direction. This valve is significant in maintaining the efficiency and reliability of the truck’s operations, particularly within the fuel or hydraulic systems.

Basic Concepts of Check Valves

A check valve, also known as a non-return valve, is a mechanical device that allows fluid to flow through it in only one direction. It operates by using a mechanism that opens to permit flow in one direction and closes to prevent reverse flow. Check valves are commonly used in fluid systems to prevent backflow, which can cause system inefficiencies or damage 1.

Purpose of the Cummins 3019794 Check Valve

The Cummins 3019794 Check Valve plays a specific role in the operation of a truck by ensuring that fluid, whether it be fuel or hydraulic fluid, flows in the correct direction within the system. This valve helps maintain system pressure and prevents fluid from flowing back into the system, which could lead to inefficiencies or potential damage to other components.

Key Features

The Cummins 3019794 Check Valve is characterized by its robust design and the materials used in its construction. It is built to withstand the demanding conditions found in commercial truck environments. Unique attributes of this valve include its precise engineering, which enhances its performance and reliability in various operating conditions.

Benefits

The advantages provided by the Cummins 3019794 Check Valve include improved system efficiency and reliability. By ensuring that fluid flows in the correct direction, this valve helps maintain optimal system performance. Additionally, its durable construction contributes to the longevity of the valve, offering cost-saving benefits over time.

Installation Considerations

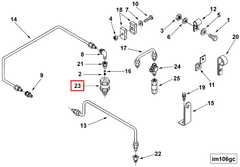

When installing the Cummins 3019794 Check Valve, it is important to follow guidelines and best practices to ensure proper integration within the truck’s system. This includes orienting the valve correctly to allow for the intended direction of fluid flow and securing it in place to prevent leaks or dislodgement.

Troubleshooting and Maintenance

Common issues that may arise with the Cummins 3019794 Check Valve include blockages or malfunctions that can impede fluid flow. Diagnostic tips for identifying these issues involve checking for signs of leakage, unusual noises, or a drop in system performance. Maintenance procedures, such as regular inspection and cleaning, can help ensure the valve’s longevity and optimal performance.

Performance in Various Conditions

The Cummins 3019794 Check Valve is designed to perform under a range of operating conditions, including varying temperatures, pressures, and load conditions. Its robust construction allows it to maintain functionality and reliability, even in the challenging environments typical of commercial truck operations.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins plays a significant role in the commercial truck industry, providing reliable and efficient components that contribute to the performance and longevity of commercial vehicles.

Role of Part 3019794 Check Valve in Engine Systems

The Cummins 3019794 Check Valve is an integral component in various engine systems, ensuring the unidirectional flow of fluids and gases. Its application spans across multiple subsystems, enhancing the efficiency and reliability of the engine.

Integration with Fuel Systems

In fuel systems, the Check Valve is typically installed in the fuel pump and fuel tubing to prevent backflow. This ensures that fuel flows consistently to the engine, maintaining optimal performance. When integrated with the Fuel Pump Repair Aftercooler Kit, it aids in regulating the fuel pressure, contributing to efficient combustion.

Role in Aftercooler Systems

The Check Valve is essential in aftercooler systems, particularly in the Aftercooler Drain Valve Mounting and Aftercooler Plumbing. It prevents the reflux of coolant, ensuring that the aftercooler operates within specified parameters. The Assembly Aftercooler Tube benefits from the Check Valve by maintaining a steady flow of coolant, which is vital for effective heat exchange.

Manifold and Press Systems

In manifold and press systems, the Check Valve is used in components such as the Manifold Press Assembly Tube, Manifold Press Line Mounting, and Manifold Pressure Tube. It ensures that pressure is maintained in the correct direction, preventing any reverse flow that could disrupt the engine’s air-fuel mixture. The Manifold Assembly Tube and Mounting and Manifold Tube also rely on the Check Valve to sustain consistent pressure levels, crucial for the engine’s performance.

Air Intake Systems

Within air intake systems, the Check Valve is incorporated into the Manifold, Air Intake, and Manifold Pressure Tube. It helps in regulating the airflow, ensuring that the engine receives a consistent supply of air. This is particularly important in high-performance engines where precise air-fuel ratios are necessary.

Plumbing and AFC Systems

The Check Valve is also vital in plumbing systems, especially in AFC (Aftercooler) Tubing and Pressure Tube Manifold. It ensures that fluids flow in the intended direction, preventing any contamination or mixing that could affect engine performance. The Plumbing, AFC, and Valve Check Manifold Press systems all benefit from the Check Valve’s ability to maintain flow integrity.

Comprehensive System Interaction

The Check Valve’s role extends to the Check Valve Manifold Press and Check Valve Mounting, where it interacts with various tubes and mounting components. Its presence in these systems ensures that all interconnected components function harmoniously, contributing to the overall efficiency and reliability of the engine.

Conclusion

The Cummins 3019794 Check Valve is a versatile and essential component that supports the efficient and reliable operation of various engine systems across different engine types. Its robust design and precise engineering make it a critical part in maintaining the performance and longevity of commercial vehicles.

-

Hilgers, Michael. Entire Vehicle: Second Edition. Springer Nature, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.