This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3071589 Check (Top Level Assembly) Valve is a component designed for use in commercial trucks. It serves a specific function within the truck’s fluid systems, contributing to the overall efficiency and reliability of the vehicle’s operations. Understanding its purpose and role is fundamental for maintaining and optimizing truck performance.

Basic Concepts of Check Valves

Check valves are mechanical devices that allow fluid to flow in one direction while preventing reverse flow. They operate using a simple mechanism where a disc or ball moves to block the flow when pressure is applied in the wrong direction. These valves are commonly used in various fluid systems, including hydraulic, pneumatic, and fuel systems, to ensure that fluid moves in the intended direction, thereby protecting components from damage and ensuring system efficiency 1.

Purpose of the 3071589 Check Valve in Truck Operations

This Cummins part plays a role in the truck’s fluid systems by ensuring that fluid flows in the correct direction. This is particularly important in systems where backflow could cause damage or reduce efficiency. By preventing reverse flow, the valve helps maintain system pressure and ensures that components receive the necessary fluid at the correct pressure and flow rate.

Key Features of the 3071589 Check Valve

The 3071589 Check Valve is characterized by its robust design and the materials used in its construction. It is built to withstand the demanding conditions found in commercial truck operations. The valve features a durable housing and a precision-machined disc or ball that ensures a tight seal against reverse flow. Additionally, it may include features such as anti-vibration mounts to enhance its performance in the dynamic environment of a moving truck 2.

Benefits of Using the 3071589 Check Valve

Incorporating this part into a truck’s fluid system can lead to improved system efficiency and reliability. By preventing backflow, the valve helps maintain consistent system pressure and flow, which can enhance the performance of other components. Additionally, its durable construction and reliable operation can contribute to reduced maintenance costs and increased uptime for the vehicle.

Installation Considerations

Proper installation of the 3071589 Check Valve is important for ensuring its effective operation. It should be installed in the correct orientation, with flow in the intended direction. Consideration should be given to the system’s requirements, including pressure and temperature ratings, to ensure compatibility with other components. Following manufacturer guidelines for installation will help ensure optimal performance and longevity of the valve 3.

Maintenance and Troubleshooting

Routine maintenance of the 3071589 Check Valve involves checking for signs of wear or damage, ensuring that the valve operates smoothly, and verifying that it is securely installed. Common issues may include leaks or reduced flow, which can often be traced to wear on the disc or seat. Troubleshooting steps may involve cleaning the valve, replacing worn components, or adjusting the installation to address any issues.

Performance in Various Conditions

The 3071589 Check Valve is designed to perform under a range of operating conditions, including varying temperatures, pressures, and fluid types. Its robust construction and precise engineering allow it to maintain its function in the challenging environments typical of commercial truck operations. Regular maintenance and proper installation are key to ensuring consistent performance across different conditions.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry, offering a wide range of products designed to meet the demanding requirements of modern transportation. The company’s commitment to innovation, quality, and customer satisfaction has solidified its position as a leader in the field.

Role of Part 3071589 Check (Top Level Assembly) Valve in Engine Systems

The 3071589 Check (Top Level Assembly) Valve is an essential component in the regulation and control of fluid dynamics within engine systems. Its primary function is to allow fluid to flow in one direction while preventing reverse flow, thereby maintaining the integrity and efficiency of the system.

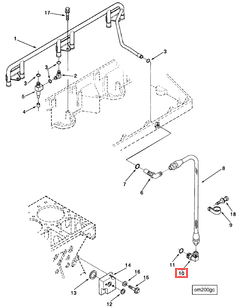

Integration with Injectors

When integrated with injectors, the Check Valve ensures that the fuel or fluid delivered is under consistent pressure. This consistency is vital for the precise operation of the injector, which relies on stable pressure to atomize the fuel effectively. The valve prevents any backflow that could disrupt the pressure, ensuring that the injector performs optimally and delivers the correct fuel quantity at the right time.

Contribution to Overall Performance

In the context of engine performance, the Check Valve plays a significant role by maintaining the desired pressure levels throughout the system. This stability is essential for the engine to operate smoothly and efficiently. By preventing reverse flow, the valve helps in reducing wear and tear on other components, thus contributing to the longevity and reliability of the engine.

Impact on Parts and Performance

The Check Valve also influences the performance of other parts within the engine system. For instance, it works in conjunction with various sensors and control units to ensure that the engine operates within specified parameters. This integration helps in optimizing the engine’s performance metrics, such as fuel efficiency, power output, and emissions.

Summary of Component Interaction

- Injectors: Ensures consistent pressure for optimal fuel delivery.

- Engine Performance: Maintains stable pressure levels for smooth operation.

- Other Parts: Contributes to the overall reliability and efficiency of the engine system.

Conclusion

The 3071589 Check (Top Level Assembly) Valve is a critical component in the fluid systems of commercial trucks, ensuring efficient and reliable operation. Its role in preventing reverse flow, maintaining system pressure, and integrating with other engine components underscores its importance in engine performance and longevity. Proper installation, maintenance, and understanding of its function are essential for maximizing the benefits of this Cummins part.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.