This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

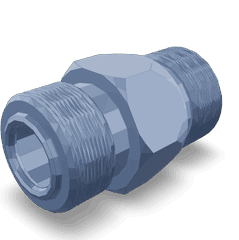

The Cummins 3090451 Check Valve is a component designed to regulate fluid flow within commercial trucks. Its purpose is to allow fluid to flow in one direction while preventing reverse flow, which is significant for maintaining the efficiency and reliability of the truck’s fluid systems 1.

Basic Concepts of Check Valves

A check valve, also known as a non-return valve, is a mechanical device that permits fluid to flow through it in only one direction. It functions by using a mechanism that opens under pressure from the correct flow direction and closes when the flow attempts to reverse. Check valves are commonly used in fluid systems to prevent backflow, which can cause system inefficiencies or damage 2.

Purpose of the 3090451 Check Valve

The Cummins 3090451 Check Valve plays a specific role in the operation of a truck by ensuring that fluid, such as coolant or lubricant, flows in the intended direction within the system. This helps maintain system pressure, prevent contamination, and ensure that components receive the necessary fluid for operation. Its function is integral to the truck’s fluid systems, contributing to overall vehicle performance and longevity 3.

Key Features

The Cummins 3090451 Check Valve is characterized by its robust design and the materials used in its construction, which are chosen for their durability and resistance to the harsh conditions found in commercial truck environments. Unique attributes of this check valve may include a spring-loaded mechanism for reliable operation, a corrosion-resistant body, and precision-machined components that ensure a tight seal and efficient flow control.

Benefits

The Cummins 3090451 Check Valve offers several benefits, including improved system efficiency by preventing backflow, which can lead to reduced wear on system components. Its reliable operation contributes to the overall reliability of the truck’s fluid systems. Additionally, by ensuring proper fluid flow and system pressure, it can help in reducing maintenance costs and downtime associated with system failures.

Installation Considerations

Proper installation of the Cummins 3090451 Check Valve is crucial for its effective operation. Best practices include ensuring the valve is installed in the correct flow direction, using the appropriate fittings and seals, and following manufacturer guidelines for torque specifications. Common pitfalls to avoid include incorrect orientation, over-tightening, and using incompatible materials that could lead to leaks or valve failure.

Troubleshooting and Maintenance

For troubleshooting common issues related to the Cummins 3090451 Check Valve, it is important to check for signs of leakage, unusual noises, or changes in system performance. Maintenance tips include regular inspection for wear or damage, cleaning the valve to remove any debris that could impede its operation, and following recommended service intervals for replacement or overhaul. These practices help ensure the valve continues to perform optimally.

Common Applications

The Cummins 3090451 Check Valve is typically applied within various truck systems where fluid flow direction needs to be controlled. Its applications may include coolant systems, lubrication circuits, and hydraulic systems. By ensuring proper fluid flow, the check valve contributes to the efficient operation and performance of these systems, enhancing the overall functionality of the vehicle.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and a commitment to quality, Cummins serves commercial, industrial, and transportation markets worldwide, providing reliable and efficient power solutions that meet the demands of today’s industries.

Compatibility with Engine Models

The Cummins Check Valve part number 3090451 is designed to fit seamlessly with several engine models, ensuring efficient operation and reliability. This check valve is integral to the engine’s fuel and lubrication systems, preventing backflow and maintaining system integrity.

KTA19GC Series

The KTA19GC engine series benefits from the 3090451 check valve, which is engineered to handle the specific demands of this engine model. The check valve ensures that fuel and lubrication flow in the correct direction, preventing any reverse flow that could compromise engine performance.

KTA19GC CM558

The KTA19GC CM558 engine, a variant of the KTA19GC series, also utilizes the 3090451 check valve. This particular model is equipped with advanced emission control systems, and the check valve plays a crucial role in maintaining the efficiency of these systems by ensuring proper fluid flow.

QSK19 Series

The QSK19 engines, including the QSK19 CM500 and QSK19 CM850 MCRS, are designed to operate under demanding conditions. The 3090451 check valve is compatible with these models, providing reliable performance in both standard and heavy-duty applications. It ensures that the engine’s fuel and lubrication systems function optimally, even under extreme conditions.

QSK19G

The QSK19G engine, another variant in the QSK19 series, also incorporates the 3090451 check valve. This engine is known for its durability and efficiency, and the check valve is a critical component in maintaining these qualities by preventing backflow and ensuring consistent system pressure.

By integrating the 3090451 check valve into these engine models, Cummins ensures that the engines operate smoothly and efficiently, providing reliable performance across various applications.

Role in Engine Systems

In the context of engine systems, the 3090451 Check Valve is instrumental in maintaining the integrity and efficiency of the lubrication circuit. This component is strategically positioned to regulate the flow of oil, ensuring that it moves in the desired direction and preventing any backflow that could compromise the system’s performance.

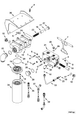

Integration with Full Flow Oil Filter

The Check Valve works in tandem with the Full Flow Oil Filter to enhance the filtration process. By allowing oil to flow towards the filter while preventing any reverse flow, it ensures that the filter receives a consistent supply of oil. This consistent flow is essential for the filter to effectively remove contaminants and maintain the cleanliness of the oil, which is vital for the longevity and performance of the engine.

Interaction with Lubricating Oil System

Within the Lubricating Oil System, the Check Valve plays a significant role in maintaining pressure and flow stability. It ensures that the lubricating oil is directed efficiently through the system, reducing the risk of oil starvation in critical engine components. This consistent oil flow is essential for reducing friction, wear, and tear on moving parts, thereby enhancing the overall efficiency and reliability of the engine.

Coordination with Lubricating Oil Filter Head

The Check Valve also interacts with the Lubricating Oil Filter Head, ensuring that the oil entering the head is free from backflow. This interaction is vital for the proper functioning of the filter head, as it relies on a steady and unidirectional flow of oil to effectively distribute it to various engine components. The Check Valve’s role here is to maintain the pressure and flow integrity, ensuring that the filter head can perform its function without any interruptions.

Conclusion

In summary, the Cummins 3090451 Check Valve is a key component in the engine’s lubrication system, working seamlessly with the Full Flow Oil Filter, Lubricating Oil System, and Lubricating Oil Filter Head to ensure optimal engine performance and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.