This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

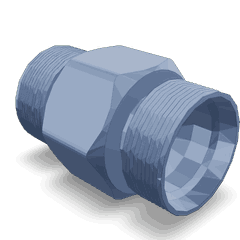

The Cummins 3335590 Check Valve is a critical component in commercial truck systems, designed to regulate fluid flow in a single direction. This ensures the efficiency and reliability of various truck systems, including fuel, lubrication, and hydraulic systems.

Basic Concepts of Check Valves

A check valve, or non-return valve, allows fluid to flow through it in only one direction. It operates by opening to permit forward flow and closing to prevent reverse flow, commonly used in fluid systems to prevent backflow and system inefficiency or damage 1.

Purpose of the Cummins 3335590 Check Valve

This Cummins part ensures that fluids, such as fuel or lubricants, flow in the correct direction within the system. It maintains system pressure, prevents contamination, and ensures components receive the necessary fluid supply for optimal performance 2.

Key Features

Constructed from durable materials, the 3335590 Check Valve includes a spring-loaded disc that regulates fluid flow. It is engineered to withstand high pressures and temperatures, suitable for demanding commercial truck applications 3.

Benefits

The 3335590 Check Valve enhances system efficiency by preventing backflow, which can lead to pressure drops and system inefficiencies. It also contributes to the overall reliability of the truck’s systems by ensuring correct fluid direction, reducing the risk of component damage due to incorrect fluid flow 4.

Installation Considerations

Proper installation of the 3335590 Check Valve is crucial for its function. This includes orienting the valve correctly to allow fluid to flow in the intended direction. Tools required may include wrenches and a torque wrench to ensure secure connections without over-tightening.

Troubleshooting Common Issues

Common issues with check valves include leaks or malfunctions due to wear or debris. Troubleshooting may involve inspecting the valve for damage, cleaning or replacing it if necessary, and ensuring correct installation. Regular maintenance can help prevent many of these issues.

Maintenance Tips

Regular inspections of the 3335590 Check Valve are recommended to check for wear or damage. Cleaning the valve according to manufacturer guidelines can prevent buildup that may affect its operation. Replacement should be considered if the valve shows significant wear or fails to operate correctly during inspections.

Manufacturer Information - Cummins

Cummins Inc. is a global leader in diesel and natural gas engines and related technologies. With a history of innovation and commitment to quality, Cummins has established itself as a trusted name in the automotive and heavy-duty truck industries. The company’s expertise in engine manufacturing extends to the production of reliable components like the 3335590 Check Valve.

Role of 3335590 Check Valve in Engine Systems

The 3335590 Check Valve is integrated into various engine systems to ensure the proper flow of fluids and gases. In retrofit kits, it enhances system efficiency by preventing backflow, which can lead to performance issues.

When paired with an Oil Control Valve (OCV) system, the check valve maintains consistent oil pressure, vital for lubrication and cooling of engine components. This ensures that the OCV can modulate oil flow accurately, contributing to optimal engine performance and longevity.

In oil replenishing systems, the check valve allows oil to flow in one direction only, preventing reverse flow that could contaminate the oil or reduce system pressure. This ensures a steady supply of clean oil to critical engine parts.

Overall, the integration of the 3335590 Check Valve in these systems enhances reliability and performance, making it a valuable component in maintaining engine health.

Conclusion

The Cummins 3335590 Check Valve is a vital component in commercial truck systems, ensuring the efficient and reliable flow of fluids. Its durable construction, key features, and benefits make it an essential part for maintaining system integrity and performance. Proper installation, regular maintenance, and understanding its role in engine systems are crucial for maximizing its effectiveness.

-

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Miedema, S. A., & Lu, Z. (2010). The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.