Introduction

The Valve Seat Cutter Kit 3376405, manufactured by Cummins, is a specialized tool designed for the maintenance and repair of heavy-duty truck engines. Cummins, a renowned name in the automotive industry, particularly in diesel engines and components, offers this kit to ensure the precision and efficiency of engine repairs. This Cummins part is integral to maintaining the optimal performance of truck engines by facilitating the accurate cutting and reshaping of valve seats.

Basic Concepts

Valve seats are components in an engine, providing a seal for the valve against the cylinder head. They ensure that the combustion process is contained within the cylinder, contributing to the engine’s efficiency and power output. Maintaining the integrity of valve seats is necessary for optimal engine performance, as worn or damaged seats can lead to leaks, reduced efficiency, and potential engine damage 1.

Purpose of the Valve Seat Cutter Kit

This part is designed to play a role in the operation and maintenance of truck engines by enabling precision cutting and reshaping of valve seats. This is particularly important during engine overhauls or when valve seats become worn or damaged. The kit allows for the restoration of the valve seat to its original specifications, ensuring a proper seal and optimal engine performance.

Key Features

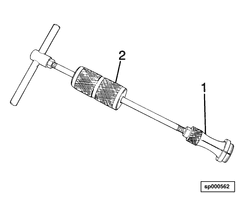

The Valve Seat Cutter Kit 3376405 incorporates several key features that enhance its functionality and effectiveness. Its design includes precision-engineered components that ensure accurate cutting and reshaping of valve seats. The kit may also feature unique technological advancements, such as adjustable cutting depths and angles, to accommodate various engine designs and requirements.

Benefits

Using the Valve Seat Cutter Kit offers several advantages. It contributes to improved engine efficiency by ensuring that valve seats are in optimal condition. This, in turn, extends the lifespan of both the valves and the seats themselves. Additionally, the kit facilitates precise repairs, reducing the likelihood of future issues and enhancing the overall reliability of the engine 2.

Operational Procedure

To use the Valve Seat Cutter Kit effectively, follow a step-by-step approach. Begin by ensuring the engine is cool and the cylinder head is securely mounted. Use the appropriate cutting tool from the kit, adjusting it to the required specifications for the valve seat being worked on. Proceed with the cutting process, following safety precautions and best practices to achieve optimal results. This may include wearing protective gear and ensuring the work area is well-ventilated.

Troubleshooting and Maintenance

Common issues that may arise when using a Valve Seat Cutter Kit include uneven cuts or difficulty in achieving the desired seat angle. Troubleshooting steps may involve re-checking the kit’s settings and ensuring the cutting tool is properly aligned. Regular maintenance of the kit, such as cleaning and inspecting components for wear, is important to ensure its longevity and effectiveness 3.

Impact on Engine Performance

Proper maintenance of valve seats using the Valve Seat Cutter Kit contributes to overall engine performance by ensuring a tight seal between the valve and the cylinder head. This leads to improved fuel efficiency, as the combustion process is more contained, and enhances engine reliability by reducing the risk of leaks and associated damage.

Cummins Overview

Cummins Inc. has a rich history in the automotive industry, particularly known for its diesel engines and related components. The company’s commitment to innovation and quality has established it as a leader in the design and manufacturing of engine technology. Cummins’ products, including the Valve Seat Cutter Kit 3376405, are designed with the aim of enhancing engine performance, reliability, and efficiency in heavy-duty applications.

Conclusion

The Valve Seat Cutter Kit 3376405 by Cummins is a vital tool for maintaining and repairing heavy-duty truck engines. Its precision-engineered components and technological advancements ensure accurate cutting and reshaping of valve seats, contributing to improved engine efficiency and reliability. Regular use and maintenance of this Cummins part are essential for optimal engine performance and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.