This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3410003 Check Valve is a specialized component designed for use in commercial truck operations. Its purpose is to regulate the flow of fluids within the truck’s systems, ensuring that fluid moves in the intended direction and preventing backflow. This valve plays a significant role in maintaining the efficiency and reliability of the truck’s fluid systems, contributing to overall vehicle performance and longevity.

Basic Concepts of Check Valves

A check valve, also known as a non-return valve, is a mechanical device that allows fluid to flow through it in only one direction. It operates by using a mechanism that opens to permit forward flow and closes to prevent reverse flow. Check valves are commonly used in various fluid systems, including hydraulic, pneumatic, and fuel systems, to ensure that fluid moves in the correct direction and to protect components from damage due to backflow 1.

Purpose of the Cummins 3410003 Check Valve

The Cummins 3410003 Check Valve is specifically designed to function within the fluid systems of commercial trucks. It plays a role in regulating the flow of fluids, such as fuel or hydraulic fluid, ensuring that these fluids move in the intended direction. By preventing backflow, the valve helps maintain system pressure, protect sensitive components, and ensure the efficient operation of the truck’s systems 2.

Key Features

The Cummins 3410003 Check Valve is characterized by several key features that enhance its performance and durability. Its design includes a robust body made from high-quality materials, ensuring resistance to corrosion and wear. The valve incorporates a precision-machined seat and a durable disc that opens and closes to regulate fluid flow. Additionally, the valve is engineered to withstand high pressures and temperatures, making it suitable for demanding commercial truck applications 3.

Benefits

The Cummins 3410003 Check Valve offers several advantages for commercial truck operators. By ensuring proper fluid flow and preventing backflow, the valve contributes to improved system efficiency and reliability. This can lead to enhanced truck performance, reduced maintenance requirements, and potential cost savings for fleet operators. The valve’s durable construction and resistance to harsh operating conditions also contribute to its longevity and reliability 4.

Installation Considerations

When installing the Cummins 3410003 Check Valve, it is important to follow guidelines and best practices to ensure proper function and compatibility with the truck’s fluid systems. The valve should be installed in the correct orientation, with the arrow indicating the direction of flow pointing towards the intended flow direction. Proper connection methods, such as using compatible fittings and seals, should be employed to ensure a secure and leak-free installation. Additionally, the valve should be compatible with the specific fluid type and system pressure to ensure optimal performance.

Troubleshooting and Maintenance

Common issues that may arise with the Cummins 3410003 Check Valve include leaks, restricted flow, or valve failure. Diagnostic tips for identifying these issues include checking for signs of fluid leakage around the valve, monitoring system pressure and flow rates, and inspecting the valve for signs of wear or damage. Maintenance procedures for the valve may include regular inspection, cleaning, and replacement of worn components to ensure optimal performance and longevity. Following the manufacturer’s recommended maintenance schedule and guidelines can help prevent issues and extend the valve’s service life.

Performance in Various Conditions

The Cummins 3410003 Check Valve is designed to perform reliably under a range of operating conditions. It is engineered to withstand extreme temperatures, high pressure, and varying fluid types commonly encountered in commercial truck applications. The valve’s robust construction and precision-machined components ensure consistent performance and durability, even in demanding environments.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to quality, innovation, and customer satisfaction in the commercial vehicle industry. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the needs of commercial truck operators and enhance the performance and reliability of their vehicles.

Cummins Check Valve Part 3410003 in K19 Engines

The Cummins Check Valve part number 3410003 is a critical component in the K19 engine series. This valve is designed to ensure that fluid flows in only one direction, preventing backflow which could otherwise lead to system inefficiencies or damage. In the K19 engines, the check valve is strategically placed to maintain the integrity of the hydraulic or fuel systems, ensuring smooth and reliable operation.

In the K19 engine family, the check valve is integral to maintaining the pressure and flow characteristics of the engine’s lubrication and fuel systems. Its placement and design are tailored to withstand the high pressures and temperatures typical of these engines, ensuring longevity and performance.

The check valve’s role is vital in maintaining the operational efficiency of the K19 engines. By preventing backflow, it helps maintain consistent system pressure, which is crucial for the engine’s performance and longevity. This component is a testament to Cummins’ commitment to quality and reliability, ensuring that the K19 engines operate at peak efficiency.

Role of Part 3410003 Check Valve in Engine Systems

The Part 3410003 Check Valve is an essential component in various engine systems, ensuring the proper flow of gases and fluids while preventing backflow. Here’s how it integrates with several key components:

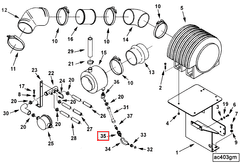

CCV System Retrofit Kit

In a CCV (Crankcase Ventilation) System Retrofit Kit, the Check Valve is positioned to regulate the flow of gases from the crankcase to the intake manifold. This ensures that blow-by gases are efficiently redirected, minimizing the risk of contamination and enhancing engine performance.

Cleaner

When integrated with an air cleaner system, the Check Valve helps maintain a consistent airflow by preventing any reverse flow that could introduce contaminants into the intake system. This ensures the air entering the engine is clean, optimizing combustion efficiency.

Air System

Within the air system, the Check Valve plays a role in maintaining pressure stability. It allows air to flow in one direction while blocking any reverse flow, which is vital for consistent engine operation and preventing potential damage from pressure fluctuations.

Crankcase Valve Drain

In conjunction with the crankcase valve drain, the Check Valve ensures that any accumulated sludge or moisture is effectively expelled from the crankcase. This prevents buildup that could lead to engine sludge, maintaining the integrity of the lubrication system.

Plumbing

In the engine’s plumbing system, the Check Valve is used to control the flow of fluids, such as oil or coolant, ensuring they move in the intended direction. This is particularly important in systems where backflow could cause contamination or reduce system efficiency.

Crankcase Breather

The Check Valve is a key component in the crankcase breather system, where it allows pressure to be released from the crankcase while preventing external contaminants from entering. This maintains a balanced pressure environment within the crankcase, enhancing engine longevity and performance.

Conclusion

The Cummins 3410003 Check Valve is a vital component in the fluid systems of commercial trucks, ensuring efficient and reliable operation by regulating fluid flow and preventing backflow. Its robust design, key features, and benefits contribute to enhanced truck performance, reduced maintenance requirements, and potential cost savings for fleet operators. Proper installation, maintenance, and understanding of its role in various engine systems are crucial for maximizing the valve’s performance and longevity.

-

Dixon, John. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩ -

Reif, Konrad (Ed.). Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer, 2014.

↩ -

Boyce, Meherwan P. Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann, 2011.

↩ -

Schneider, Wolf-Henning. Pistons and Engine Testing. Springer Nature, 2016.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.