This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

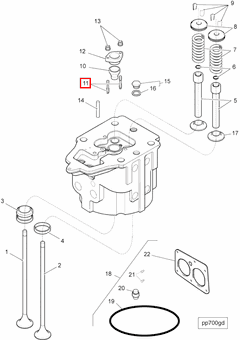

Introduction

The Valve Crosshead Guide 3420606, manufactured by Cummins, is a critical component in several engine models. This part is designed to ensure the smooth and precise movement of the valve crosshead, which is essential for the engine’s operation 1.

Basic Concepts

Valve crosshead guides are integral to the valve train system of an engine. They facilitate the smooth operation of the valves by guiding the valve stems as they move up and down. This guidance ensures that the valves open and close at the correct angles and times, which is vital for the engine’s performance and efficiency 2. By maintaining precise valve alignment, these guides help in achieving optimal combustion, thereby enhancing the engine’s overall efficiency.

Purpose and Role

The Valve Crosshead Guide 3420606 is specifically designed to maintain the alignment of the valve stems in Cummins engines. Its role is to ensure that the valves operate correctly within the engine cylinder, which is crucial for the engine’s performance. Proper valve function is necessary for efficient combustion, which directly impacts the engine’s power output and fuel efficiency 3.

Key Features

The Valve Crosshead Guide 3420606 is crafted from high-quality materials, ensuring durability and resistance to wear. Its design is tailored to fit precisely within the engine, providing stable and reliable valve stem guidance. The guide’s material composition and design characteristics are optimized to withstand the high temperatures and pressures within the engine, contributing to its longevity and performance.

Benefits

Utilizing the Valve Crosshead Guide 3420606 in Cummins engines offers several advantages. It contributes to improved engine efficiency by ensuring that the valves operate smoothly and precisely. This precise operation reduces wear on valve components, leading to enhanced engine reliability and longevity. Additionally, the guide’s durable construction helps in maintaining engine performance over time, reducing the need for frequent replacements.

Troubleshooting and Maintenance

Common issues with valve crosshead guides may include wear or damage due to high engine temperatures and pressures. Regular inspection and maintenance are recommended to identify any signs of wear or damage early. Maintenance practices should include checking for proper valve alignment and ensuring that the guide is free from debris or obstructions that could affect its performance. Addressing these issues promptly can help in maintaining optimal engine performance and preventing more significant engine problems.

Installation and Replacement

When installing or replacing the Valve Crosshead Guide 3420606, it is important to follow the manufacturer’s instructions carefully. This process may require specific tools and should be performed with attention to detail to ensure that the guide is properly seated and aligned within the engine. Taking the necessary precautions during installation will help in achieving the best performance and longevity from the component.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and quality, Cummins has established a strong reputation in the automotive industry for producing reliable and high-performance engine components. The company’s commitment to quality and excellence is evident in its wide range of products, including the Valve Crosshead Guide 3420606, which is designed to meet the demanding requirements of heavy-duty truck engines.

Role of Part 3420606 Valve Crosshead Guide in Engine Systems

The Valve Crosshead Guide, identified by part number 3420606, is an integral component within various engine systems, particularly those involving the cylinder assembly head and cylinder head. This guide ensures the proper alignment and movement of the valve within the cylinder head, contributing to the overall efficiency and performance of the engine.

In the context of a Cylinder Assembly Head, the Valve Crosshead Guide works in conjunction with the valve mechanism to maintain precise valve operation. It supports the valve stem, reducing wear and tear, and ensuring smooth operation during the engine’s combustion cycle.

When considering a Cylinder Head Overhaul Kit, the inclusion of the Valve Crosshead Guide is essential. This kit often comprises various components aimed at restoring the cylinder head to its optimal condition. The guide plays a role in facilitating the correct installation and function of new or refurbished valve components.

In a Cylinder Sub-Assembly Head, the Valve Crosshead Guide is similarly important. This sub-assembly typically includes the cylinder head along with other attached components. The guide ensures that the valve stem remains aligned, which is vital for the sub-assembly’s performance and durability.

For the Head Cylinder Assembly and Head Cylinder Sub-Assembly, the Valve Crosshead Guide is a key element that ensures the valve operates within its designed parameters. It helps in minimizing the friction between the valve stem and the cylinder head, which is crucial for the longevity and efficiency of the assembly.

In the Head Gas Cylinder Assembly, the guide assists in maintaining the integrity of the valve seal. Proper alignment and smooth operation of the valve, facilitated by the guide, prevent gas leaks and ensure that the combustion process is efficient.

Lastly, in an Overhaul Kit, the Valve Crosshead Guide is often a replacement part. Its role in the overhaul process is to ensure that the cylinder head components are reassembled correctly, promoting reliable engine performance post-overhaul.

Conclusion

The Valve Crosshead Guide 3420606 by Cummins is a vital component in ensuring the efficient and reliable operation of heavy-duty truck engines. Its role in maintaining valve alignment and facilitating smooth valve operation contributes significantly to engine performance and longevity. Regular maintenance and proper installation are key to maximizing the benefits of this part.

-

Reif, Konrad, ed. Gasoline Engine Management Systems and Components. Springer Vieweg, 2015.

↩ -

Asef, Pedram, Sanjeevikumar Padmanaban, and Andrew Lapthorn. Modern Automotive Electrical Systems. Wiley, 2022.

↩ -

Eret, Angelina. Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature, 2024.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.