This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3423661 Valve Spring is a component designed for use in commercial truck engines. Its purpose is to ensure the proper operation of the engine’s valve system. This valve spring is significant in maintaining the efficiency and reliability of truck engines, contributing to their overall performance and longevity 1.

Basic Concepts of Valve Springs

Valve springs are mechanical components found in internal combustion engines. They function by applying force to keep the valves closed against the pressure of the combustion chamber. This ensures that the valves open and close at the correct times in synchronization with the engine’s operation. The importance of valve springs lies in their role in maintaining valve operation, which is essential for the engine’s performance and efficiency 2.

Purpose of the Cummins 3423661 Valve Spring

The Cummins 3423661 Valve Spring plays a role in the operation of a truck engine by controlling the movement of the valves. It ensures that the valves open and close in accordance with the engine’s timing, which is essential for proper combustion and exhaust processes. By maintaining consistent valve operation, this valve spring helps to ensure the engine performs efficiently and reliably 3.

Key Features

The Cummins 3423661 Valve Spring is distinguished by several specific features. These include its material composition, which is designed to withstand the high temperatures and pressures within a truck engine. The design of the spring is tailored to provide the necessary force for valve operation under various engine conditions. Additionally, the manufacturing quality ensures that the spring meets the high standards required for heavy-duty truck applications.

Benefits

The Cummins 3423661 Valve Spring offers several advantages. It contributes to improved engine efficiency by ensuring precise valve timing. The durability of the spring allows it to withstand the demanding conditions of heavy-duty truck engines. Furthermore, its reliability reduces the likelihood of engine failures, providing peace of mind for truck operators.

Installation Considerations

When installing the Cummins 3423661 Valve Spring, it is important to follow guidelines and best practices. This includes using the necessary tools to ensure proper fitment and function. Procedures should be carefully followed to avoid damage to the spring or other engine components. Precautions, such as checking for correct valve clearance and ensuring the spring is seated properly, are crucial for the spring’s effective operation.

Troubleshooting Common Issues

Common problems associated with valve springs include spring failure or valve train noise. These issues can often be identified through symptoms such as engine misfires or unusual noises. Diagnostic procedures may involve inspecting the spring for signs of wear or damage. Repair procedures could include replacing the spring or addressing any underlying issues that may have caused the failure.

Maintenance Tips

To prolong the service life of the Cummins 3423661 Valve Spring, regular maintenance is recommended. This includes conducting regular inspections to check for signs of wear or damage. Lubrication of the valve train components can help reduce friction and wear. Replacement intervals should be based on manufacturer guidelines to ensure the spring continues to function effectively.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its wide range of engine and power generation products. With a history of innovation and quality, Cummins has built a reputation for producing reliable and efficient engines. The company’s product range includes engines, filtration systems, and other components designed to meet the needs of heavy-duty truck applications.

Compatibility of Cummins 3423661 Valve Spring

The Valve Spring part 3423661, manufactured by Cummins, is a critical component that is compatible with several engine models. This part is designed to ensure the proper operation of the engine’s valve mechanism, maintaining the seal between the valve and the cylinder head.

For the engines QSV81G, QSV91-G4 CM558/CM700 V102, and QSV91G, the Valve Spring part 3423661 is engineered to fit seamlessly, providing the necessary force to keep the valves closed during the engine’s operation. This ensures that the engine runs smoothly and efficiently, with minimal wear and tear.

Similarly, for the engines QSW/QSV82, QSW27, QSW36, and QSW73, the Valve Spring part 3423661 is also a perfect fit. It is designed to withstand the high pressures and temperatures within the engine, ensuring that the valves operate correctly and the engine performs optimally.

The compatibility of the Valve Spring part 3423661 across these engines highlights its versatility and the high-quality standards set by Cummins. This part is essential for maintaining the engine’s performance and longevity, making it a reliable choice for these specific engine models.

Role of Part 3423661 Valve Spring in Engine Systems

The part 3423661 Valve Spring is an essential component within various engine systems, ensuring the proper operation of the valve train. Its primary function is to maintain valve closure by counteracting the centrifugal force generated during engine operation. This allows for precise valve timing and efficient engine performance.

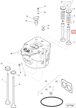

Integration with Engine Components

-

Cylinder Head and Valve Assembly: The Valve Spring is integral to the cylinder head and valve assembly. It ensures that the valves remain closed except when actuated by the camshaft. This is vital for maintaining compression within the combustion chamber and ensuring that the air-fuel mixture is ignited at the correct time.

-

Camshaft and Camshaft Mounting: When the camshaft rotates, it opens the valves via the camshaft mounting and the valve train components. The Valve Spring then returns the valve to its closed position once the camshaft lobe has passed. This repetitive action is fundamental to the engine’s operation.

-

Cylinder Head Kit and Overhaul Kit: In a cylinder head kit or overhaul kit, the Valve Spring is often included to ensure that all components work harmoniously. These kits are designed to restore or upgrade the cylinder head, and the Valve Spring plays a key role in this process by providing the necessary force to keep the valves in check.

-

Connecting Rod and Piston: Although the Valve Spring does not directly interact with the connecting rod and piston, its function is indirectly related. Proper valve operation ensures that the air-fuel mixture is admitted and exhausted at the correct times, which directly affects the performance and efficiency of the piston and connecting rod.

-

Head Assembly with Valves: In a head assembly with valves, the Valve Spring ensures that each valve operates within its designed parameters. This is important for maintaining engine balance and preventing issues such as valve float, which can occur at high RPMs if the spring is not up to the task.

-

Performance Parts: When upgrading to performance parts, the Valve Spring often needs to be replaced with a higher-rated spring to handle increased valve speeds and pressures. This ensures that the engine can operate at higher RPMs without compromising valve train integrity.

Conclusion

In summary, the part 3423661 Valve Spring is a fundamental component that ensures the reliable and efficient operation of various engine systems. Its role in maintaining valve timing and compression is indispensable for the overall performance and longevity of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.