This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3425873 Check Valve is a component designed for use in commercial truck systems. Manufactured by Cummins Inc., a leader in the automotive and heavy-duty truck parts industry, this check valve serves a specific purpose within the operational framework of trucks, ensuring the efficient and reliable performance of various systems.

Basic Concepts of Check Valves

A check valve, also known as a non-return valve, is a device that allows fluid to flow in one direction while preventing its flow in the opposite direction. This is achieved through a mechanism that opens under the pressure of the fluid moving in the desired direction and closes when the pressure reverses. Check valves are commonly used in fluid systems to maintain pressure, prevent backflow, and protect components from damage due to reverse flow 1.

Purpose of the 3425873 Check Valve in Truck Operations

The Cummins 3425873 Check Valve plays a role in the operation of commercial trucks by ensuring the unidirectional flow of fluids within the fuel, lubrication, or hydraulic systems. Its function is to prevent backflow, which could lead to system inefficiencies or damage. By maintaining the integrity of the fluid flow, this check valve contributes to the overall performance and reliability of the truck’s systems 2.

Key Features

The Cummins 3425873 Check Valve is characterized by its robust design and the use of high-quality materials, which enhance its performance and durability. Key features include a precision-machined body, a durable spring mechanism, and a seal designed to withstand high pressures and temperatures. These attributes ensure the valve operates effectively under demanding conditions typical of commercial truck operations 3.

Benefits of Using the 3425873 Check Valve

Utilizing the Cummins 3425873 Check Valve offers several advantages. It contributes to improved system efficiency by ensuring consistent fluid flow direction, enhances reliability by preventing backflow-related issues, and can lead to cost savings through reduced maintenance needs and extended component lifespan. Its design and materials also contribute to the valve’s durability, making it a reliable choice for commercial truck applications.

Installation and Integration

Proper installation of the Cummins 3425873 Check Valve is crucial for its effective operation within truck systems. Installation guidelines recommend ensuring the valve is correctly oriented to allow fluid flow in the intended direction. It is also important to verify that the valve is compatible with the specific system it will be integrated into, following any manufacturer-specified prerequisites or considerations to ensure optimal performance.

Troubleshooting and Maintenance

Common issues with the Cummins 3425873 Check Valve may include leakage, failure to open or close properly, or damage to the seal or spring mechanism. Diagnostic methods involve checking for proper orientation, inspecting for physical damage, and testing the valve’s operation under system pressure. Maintenance practices include regular inspection for wear or damage, cleaning to remove any debris that may affect operation, and replacement of worn components to ensure longevity and optimal performance.

Performance in Various Conditions

The Cummins 3425873 Check Valve is designed to perform under a range of operating conditions, including extreme temperatures and high-pressure environments. Its materials and construction allow it to withstand the rigors of commercial truck operations, ensuring reliable performance regardless of the external conditions.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and commitment to quality, Cummins serves customers in approximately 190 countries and territories through a network of more than 600 company-owned and independent distributor facilities and more than 7,200 dealer locations. Cummins’ product range includes engines, related technologies, and complete power systems for on-highway, off-highway, and stationary applications.

Cummins Check Valve Part 3425873 Compatibility

The Cummins Check Valve part number 3425873 is designed to fit seamlessly with a variety of engine models, ensuring optimal performance and reliability. This check valve is engineered to prevent backflow in the engine’s system, maintaining the integrity of the hydraulic or fuel systems.

QSW/QSV82 Engines

For the QSW/QSV82 engines, the check valve part 3425873 is a critical component that ensures the smooth operation of the engine’s hydraulic system. Its precise fit and robust construction make it an ideal choice for these engines, providing the necessary control and efficiency.

QSW27 and QSW36 Engines

Similarly, the QSW27 and QSW36 engines benefit from the use of the Cummins Check Valve part 3425873. These engines, which are part of the same family, share common design elements that make this check valve a perfect fit. Its installation in these engines helps maintain the system’s pressure and flow, ensuring the engines run smoothly and efficiently.

QSW73 Engines

The QSW73 engines also integrate the Cummins Check Valve part 3425873 effectively. This part is designed to handle the specific demands of the QSW73 engines, providing reliable backflow prevention and contributing to the overall performance of the engine.

By using the Cummins Check Valve part 3425873 across these engines, users can expect enhanced system performance, reduced wear and tear, and improved operational efficiency.

Role of Part 3425873 Check Valve in Engine Systems

The Part 3425873 Check Valve is an essential component in ensuring the proper function and efficiency of various engine systems. Its primary role is to regulate the flow of air, preventing backflow and maintaining consistent pressure levels within the system.

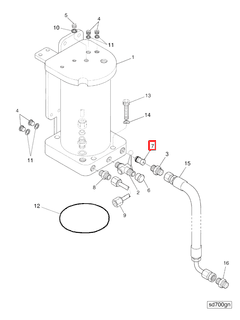

Integration with Air Assembly Tank

When integrated with the Air Assembly Tank, the Check Valve ensures that the compressed air stored within the tank is not lost due to backflow. This maintains the required pressure levels, allowing the tank to efficiently supply air to other components as needed.

Function within Air Shutdown Device

In the Air Shutdown Device, the Check Valve plays a significant role in controlling the airflow. It prevents the reverse flow of air, which could otherwise disrupt the shutdown process. This ensures that the device operates smoothly, providing a reliable means to halt air supply when necessary.

Coordination with Air Shutdown

The Check Valve works in tandem with the Air Shutdown system to enhance overall system reliability. By preventing backflow, it ensures that the shutdown mechanism functions without interference, thereby maintaining the integrity of the air supply system during operational pauses or emergencies.

Overall System Efficiency

By preventing backflow and regulating air pressure, the Part 3425873 Check Valve contributes to the efficient operation of the entire engine system. It ensures that components receive a consistent and reliable air supply, which is vital for optimal performance and longevity of the engine.

Conclusion

The Cummins 3425873 Check Valve is a critical component in the maintenance and operation of commercial truck systems. Its design, features, and benefits contribute to the efficiency, reliability, and durability of truck systems. Proper installation, maintenance, and understanding of its role in various engine systems are essential for maximizing its performance and ensuring the longevity of the systems it serves.

-

Modern Automotive Electrical Systems, Pedram Asef, Sanjeevikumar Padmanaban, and Andrew Lapthorn, Wiley, 2022.

↩ -

An Introduction to Modern Vehicle Design, Julian Happian-Smith, Butterworth-Heinemann, 2002.

↩ -

Systems Engineering for Automotive Powertrain Development, Hannes Hick, Klaus Kupper, and Helfried Sorger, Springer, 2021.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.