This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

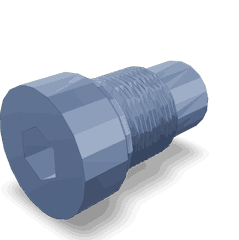

The Cummins 3688359 Check Valve is a component designed for use in the fluid systems of commercial trucks. Its purpose is to allow fluid to flow in one direction while preventing reverse flow, which helps maintain system pressure and efficiency. This valve is significant in the operation of commercial trucks as it ensures the proper functioning of fluid systems, contributing to the overall performance and reliability of the vehicle 1.

Basic Concepts of Check Valves

A check valve, also known as a non-return valve, is a mechanical device that permits fluid to flow through it in only one direction. It operates by using a movable element, such as a flap or a ball, that opens under the pressure of the fluid flowing in the correct direction and closes when the flow attempts to reverse. Check valves are commonly used in various fluid systems, including hydraulic, pneumatic, and water systems, to prevent backflow and maintain system integrity 3.

Role of the 3688359 Check Valve in Truck Operation

The Cummins 3688359 Check Valve plays a specific role in the fluid systems of commercial trucks by ensuring that fluid flows in the intended direction. It is typically placed in the system where reverse flow could cause issues, such as in fuel lines or hydraulic systems. By preventing backflow, the valve helps maintain system pressure, ensures efficient operation, and protects other components from damage due to incorrect fluid flow 1.

Key Features

The Cummins 3688359 Check Valve is characterized by several key features that enhance its performance and durability. Its design includes a robust movable element that effectively seals against reverse flow. The valve is constructed from high-quality materials that resist corrosion and wear, ensuring long-term reliability. Additionally, it may feature unique attributes such as a compact design for easy installation in tight spaces or a pressure relief mechanism to protect the system from overpressure situations 2.

Benefits of Using the 3688359 Check Valve

Utilizing the Cummins 3688359 Check Valve in commercial truck fluid systems offers several advantages. It contributes to improved system efficiency by ensuring fluid flows in the correct direction, reducing the risk of system malfunctions. The valve’s design and materials lead to reduced maintenance needs, as it is built to withstand the harsh conditions of truck operations. Furthermore, its reliable performance enhances the overall reliability of the truck’s fluid systems, contributing to safer and more efficient vehicle operation 1.

Installation Considerations

When installing the Cummins 3688359 Check Valve, it is important to follow guidelines and best practices to ensure proper function. This may include ensuring the valve is correctly oriented to allow fluid flow in the intended direction and securing it firmly in place to prevent leaks. Special tools or prerequisites may be required depending on the specific application, so it is advisable to consult the manufacturer’s instructions for detailed guidance 2.

Troubleshooting Common Issues

Common problems associated with check valves include leakage, failure to open or close properly, and blockages. Diagnosing these issues may involve checking for physical damage, ensuring the valve is correctly installed, and inspecting the fluid for contaminants that could cause blockages. Recommended solutions may include cleaning the valve, replacing damaged components, or installing a new valve if necessary 1.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3688359 Check Valve, regular maintenance practices are recommended. This includes periodic inspection for signs of wear or damage, cleaning the valve to remove any buildup that could impede its function, and ensuring it remains securely installed. Following these maintenance tips can help prevent issues and ensure the valve continues to operate effectively 1.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance products. Its extensive product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle operations 2.

Compatibility of Cummins Check Valve 3688359

The Cummins Check Valve part number 3688359 is designed to ensure the smooth operation of various Cummins engines. This part is engineered to maintain the integrity of the fuel system by preventing backflow, which can cause inefficiencies and potential damage to the engine.

ISX15 Series

The ISX15 series, including models such as the CM2250 SN and CM2350 X101, benefits from the use of the 3688359 check valve. This valve is essential in maintaining the correct fuel pressure and flow, ensuring that the engine operates at peak performance levels.

QSX15 Series

For the QSX15 engines, the check valve is equally important. Models such as the CM2250 and CM2250 ECF rely on this component to prevent fuel from flowing back into the fuel tank, which can lead to contamination and reduced efficiency. Similarly, the CM2350 X105 model also incorporates this check valve to maintain optimal fuel system integrity.

X15 Series

The X15 CM2350 X116B engine also utilizes the 3688359 check valve. This part is crucial for maintaining the fuel system’s efficiency and reliability, ensuring that the engine performs consistently under various operating conditions.

By integrating the 3688359 check valve into these engines, Cummins ensures that the fuel system operates smoothly, preventing backflow and maintaining the necessary fuel pressure for optimal engine performance 2.

Role of Part 3688359 Check Valve in Engine Systems

In the orchestration of engine systems, the part 3688359 Check Valve assumes a significant role, particularly in conjunction with the filter, fuel, and fuel filter head. This component is instrumental in maintaining the integrity and efficiency of the fuel delivery system.

When fuel is drawn from the tank, it passes through the fuel filter, where impurities are removed to ensure clean fuel reaches the engine. The Check Valve, positioned downstream of the filter, prevents any backflow of fuel, which could otherwise contaminate the filtered fuel or cause pressure fluctuations within the system.

The fuel filter head, which often houses the filter element, is another point where the Check Valve’s function is vital. It ensures that the filtered fuel maintains a consistent flow towards the engine, without any risk of reverse flow that could disrupt the filtration process or lead to inefficient engine performance.

In summary, the part 3688359 Check Valve works in harmony with the filter, fuel, and fuel filter head to uphold the quality and pressure of the fuel supply, contributing to the overall reliability and performance of the engine system 3.

Conclusion

The Cummins 3688359 Check Valve is a critical component in the fluid systems of commercial trucks, ensuring efficient and reliable operation. Its role in preventing backflow, maintaining system pressure, and protecting other components from damage underscores its importance in truck maintenance and performance. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part, contributing to the overall efficiency and reliability of commercial truck operations.

-

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ ↩ ↩ ↩ ↩ -

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩ ↩ ↩ ↩ -

Stiesch, Gunnar. Modeling Engine Spray and Combustion Processes. Springer Verlag, 2003.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.