This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3696142 Valve Spring is a component designed for use in heavy-duty truck engines. Its purpose is to ensure the proper operation of the engine’s valve train by maintaining valve closure under various engine conditions. The significance of this valve spring lies in its ability to contribute to the overall performance and reliability of the engine, particularly in demanding applications where durability and efficiency are paramount.

Basic Concepts of Valve Springs

Valve springs are mechanical components found in internal combustion engines. Their general function is to keep the valves in contact with their respective valve seats when the engine is not in the valve opening phase. This ensures that the valves remain closed during the compression and combustion phases, preventing the escape of air-fuel mixture or exhaust gases. Valve springs operate by compressing during the valve opening event and then returning to their original shape, thereby closing the valve 1.

Role of the 3696142 Valve Spring in Truck Operation

The Cummins 3696142 Valve Spring plays a specific role in the engine’s valve train by ensuring that the valves open and close at the correct times and with the appropriate force. This is particularly important in heavy-duty truck engines, where the valve train is subjected to high stresses and rapid cycling. The proper function of this valve spring contributes to engine performance and efficiency by maintaining valve timing and sealing, which are critical for optimal combustion and power output 2.

Key Features of the 3696142 Valve Spring

The design and construction of the Cummins 3696142 Valve Spring include several features that enhance its performance. These features may include a specific material composition that provides the necessary strength and durability, a coil configuration that allows for the required spring rate, and other unique attributes that ensure it can withstand the high stresses of heavy-duty applications. The precise engineering of this valve spring is aimed at providing reliable valve operation under a wide range of engine operating conditions 3.

Benefits of Using the 3696142 Valve Spring

The advantages provided by the Cummins 3696142 Valve Spring include improved engine reliability, as it is designed to withstand the rigors of heavy-duty use. It also contributes to enhanced performance under high stress, ensuring that the engine can operate efficiently even under demanding conditions. Additionally, the longevity of this valve spring in heavy-duty applications is a significant benefit, as it reduces the need for frequent replacements and maintenance 4.

Troubleshooting Common Issues with Valve Springs

Identifying and addressing common problems associated with valve springs, such as spring failure, valve train noise, and performance issues, is important for maintaining engine health. Symptoms of valve spring problems may include misfires, reduced engine performance, or unusual noises from the valve train. Proper diagnosis and timely replacement of faulty valve springs are necessary to prevent further engine damage and ensure continued reliable operation 5.

Maintenance Tips for Valve Springs

To ensure optimal performance of valve springs, regular inspection procedures should be followed. This includes checking for signs of wear, deformation, or failure. Replacement guidelines should be adhered to, based on the manufacturer’s recommendations or when signs of distress are observed. Best practices for prolonging spring life include proper engine maintenance, such as regular oil changes and following the recommended service intervals for the engine 6.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to quality is evident in its product range, which is designed to meet the demanding requirements of heavy-duty applications. Cummins’ focus on innovation ensures that its products, including the 3696142 Valve Spring, are at the forefront of technology and performance in the industry.

Valve Spring Part 3696142 Compatibility with Cummins Engines

The Valve Spring part 3696142, manufactured by Cummins, is designed to fit into a variety of Cummins engine models. Below is a detailed description of its compatibility with the specified engines:

ISG11 CM2880 G108 and ISG12 CM2880 G107

The Valve Spring part 3696142 is compatible with the ISG11 CM2880 G108 and ISG12 CM2880 G107 engines. These engines are part of the Cummins ISG series, known for their reliability and performance in industrial applications. The valve spring ensures proper valve operation, maintaining the engine’s efficiency and longevity.

ISG12 G CMOH6.0 G111

The Valve Spring part 3696142 is also suitable for the ISG12 G CMOH6.0 G111 engine. This engine variant is designed to deliver robust power, making it ideal for heavy-duty applications. The valve spring’s precise fitment is crucial for the engine’s smooth operation and performance.

QSG12 CM2880 G112

The QSG12 CM2880 G112 engine is another model that the Valve Spring part 3696142 fits. This engine is part of the Cummins QSG series, which is engineered for high-performance and durability in demanding environments. The valve spring’s role in this engine is to ensure the valves open and close at the correct times, contributing to the engine’s overall efficiency.

QSG12/X12 CM2350 G110

The Valve Spring part 3696142 is compatible with the QSG12/X12 CM2350 G110 engine. This model combines the features of the QSG and X12 series, offering a balance of power and efficiency. The valve spring’s fitment is essential for maintaining the engine’s performance and reliability.

X11 CM2670 X126B and X12 CM2350 X119B

The Valve Spring part 3696142 fits into both the X11 CM2670 X126B and X12 CM2350 X119B engines. These engines are part of the Cummins X series, known for their versatility and performance in various applications. The valve spring ensures that the valves operate correctly, which is vital for the engine’s smooth running and longevity.

X12 CM2670 X121B and X12N CMMDG1 X143B

The Valve Spring part 3696142 is also compatible with the X12 CM2670 X121B and X12N CMMDG1 X143B engines. These engines are part of the Cummins X series, designed to deliver high performance and efficiency. The valve spring’s precise fitment is crucial for the engine’s operation, ensuring that the valves open and close at the correct times.

X13 CM2670 X122B

Lastly, the Valve Spring part 3696142 fits into the X13 CM2670 X122B engine. This engine is part of the Cummins X series, offering a combination of power and efficiency. The valve spring’s role in this engine is to ensure the valves operate correctly, contributing to the engine’s overall performance and reliability.

Role of Part 3696142 Valve Spring in Engine Systems

Part 3696142 Valve Spring is integral to the operation of several key engine components, ensuring the efficient and reliable functioning of the engine’s valve train system.

Interaction with the Camshaft

The Valve Spring works in conjunction with the camshaft to control the opening and closing of the engine’s valves. As the camshaft lobes rotate, they push against the valve through the rocker lever, causing it to open. The Valve Spring then ensures that the valve returns to its closed position once the camshaft lobe moves away, maintaining the precise timing required for optimal engine performance.

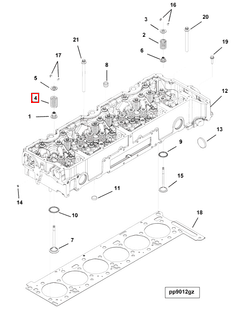

Coordination with the Cylinder Head

Positioned within the cylinder head, the Valve Spring plays a vital role in managing the valve’s movement. It ensures that the valve seals properly against the cylinder head, preventing any leakage of air or fuel that could compromise combustion efficiency. The spring’s design and material are engineered to withstand the high temperatures and pressures within the cylinder head, ensuring durability and consistent performance.

Integration with the Cylinder Top Level Assembly Head

In engines with a cylinder top level assembly head, the Valve Spring is essential for maintaining the integrity of the valve operation. This assembly often includes complex geometries and materials to enhance engine efficiency. The Valve Spring must be capable of handling the dynamic loads and thermal stresses associated with this advanced design, ensuring reliable valve actuation and sealing.

Relationship with the Injector

Although the injector and valve operate in different phases of the engine cycle, the efficient operation of the Valve Spring indirectly supports the injector’s function. Proper valve timing and sealing, facilitated by the Valve Spring, ensure that the air-fuel mixture is correctly prepared and delivered to the combustion chamber. This, in turn, allows the injector to deliver fuel at the optimal moment, enhancing combustion efficiency and overall engine performance.

Collaboration with the Rocker Lever

The rocker lever acts as a force multiplier between the camshaft and the valve. The Valve Spring counteracts this force, ensuring that the valve returns to its seat with the correct speed and force. This interaction is essential for maintaining valve train balance and preventing valve float at high engine speeds, which can lead to decreased performance and potential engine damage.

Conclusion

In summary, Part 3696142 Valve Spring is a key component in the valve train system, working seamlessly with the camshaft, cylinder head, cylinder top level assembly head, injector, and rocker lever to ensure efficient and reliable engine operation. Its role in maintaining valve timing and sealing is critical for optimal combustion and power output, making it an essential part of heavy-duty truck engines.

-

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ -

Hu, H., Baseley, S. J., & Song, X. (2021). Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International.

↩ -

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Quigley, J. M. (2023). SAE International’s Dictionary of Testing, Verification and Validation. SAE International.

↩ -

Cummins Inc. (n.d.). Owners Manual for QSK19 CM2150 MCRS (Manufactured in India). Bulletin Number 4358454.

↩ -

Cummins Inc. (n.d.). Owners Manual for QSK19 CM2150 MCRS (Manufactured in India). Bulletin Number 4358454.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.