This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3696764 Intake Valve is engineered for commercial trucks, specifically within Cummins engines. It regulates air flow into the engine’s combustion chambers, ensuring efficient operation by allowing precise control over air intake, which is crucial for combustion and overall engine performance.

Basic Concepts of Intake Valves

An intake valve in internal combustion engines allows air, and often a mixture of air and fuel, to enter the engine’s cylinders during the intake stroke. The efficiency of this process directly impacts the engine’s performance, including power output, fuel efficiency, and emissions levels. Intake valves must open and close at precise times to optimize engine operation 1.

Role of the Cummins 3696764 Intake Valve in Truck Operation

The Cummins 3696764 Intake Valve is integral to the engine’s operation in commercial trucks. It facilitates the intake of air into the combustion chamber, where it mixes with fuel for combustion. The valve’s design and timing contribute to the engine’s combustion efficiency, affecting both power output and fuel consumption. By ensuring a consistent and controlled air supply, this valve helps maintain engine performance under varying load conditions 2.

Key Features of the Cummins 3696764 Intake Valve

The Cummins 3696764 Intake Valve is characterized by its robust design and construction. It is made from high-quality materials that offer durability and resistance to the high temperatures and pressures within the engine. The valve’s size and shape are optimized for efficient air flow, and it features a precise manufacturing process to ensure it meets the stringent requirements of commercial truck engines. These attributes contribute to its performance and longevity 3.

Benefits of Using the Cummins 3696764 Intake Valve

Utilizing the Cummins 3696764 Intake Valve in commercial trucks offers several advantages. It contributes to improved engine performance by ensuring efficient air intake, which is crucial for optimal combustion. This efficiency can lead to increased fuel economy, reducing operating costs. Additionally, the valve’s durable construction and precise engineering enhance the reliability of the engine, minimizing the risk of failures and the need for frequent maintenance.

Troubleshooting Common Issues with Intake Valves

Intake valves, including the Cummins 3696764, may encounter issues such as leaks, sticking, or damage over time. Identifying these problems early is important for maintaining engine performance. Leaks can result in reduced engine efficiency, while sticking valves may lead to incomplete combustion. Regular inspections and maintenance can help address these issues, ensuring the valve continues to function correctly.

Maintenance Tips for Intake Valves

To ensure the optimal performance and longevity of intake valves, regular maintenance is recommended. This includes cleaning the valves to remove any deposits that may accumulate, inspecting them for signs of wear or damage, and replacing them according to the manufacturer’s guidelines or when performance issues arise. Proper maintenance of intake valves contributes to the overall efficiency and reliability of the engine.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s commitment to excellence is reflected in its wide range of products, which are designed to meet the demanding requirements of commercial applications, ensuring reliability, performance, and efficiency.

Compatibility of Cummins Part 3696764 Intake Valve with Various Engines

The Cummins part 3696764 Intake Valve is designed to fit seamlessly with a range of engine models, ensuring optimal performance and reliability. Here is a detailed breakdown of its compatibility:

ISG11 CM2880 G108 and ISG12 CM2880 G107

The part 3696764 Intake Valve is compatible with both the ISG11 CM2880 G108 and ISG12 CM2880 G107 engines. These engines are known for their robust design and efficiency, and the intake valve ensures that they maintain their performance standards.

QSG12 CM2880 G112

The QSG12 CM2880 G112 engine also benefits from the use of the Cummins part 3696764 Intake Valve. This engine variant is engineered for high-performance applications, and the intake valve plays a crucial role in its operation.

QSG12/X12 CM2350 G110

The QSG12/X12 CM2350 G110 engine is another model that is compatible with the part 3696764 Intake Valve. This engine is designed for specific applications that require a balance of power and efficiency, and the intake valve is a key component in achieving this balance.

X12 CM2670 X121B and X13 CM2670 X122B

Lastly, the X12 CM2670 X121B and X13 CM2670 X122B engines are also compatible with the Cummins part 3696764 Intake Valve. These engines are part of a series that is known for its versatility and adaptability to various operational conditions. The intake valve ensures that these engines perform at their best across different scenarios.

Role of Part 3696764 Intake Valve in Engine Systems

The part 3696764 intake valve is a critical component in the orchestration of engine performance, working in concert with several key engine systems.

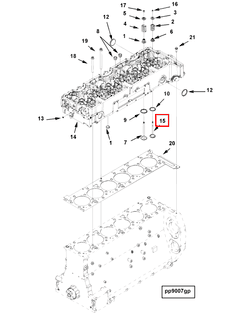

Interaction with the Cylinder Head

The intake valve is mounted within the cylinder head, where it plays a significant role in the engine’s breathing process. It opens to allow the air-fuel mixture into the combustion chamber and closes to ensure the mixture is contained during compression and combustion. The precise fit and seal of the intake valve within the cylinder head are vital for maintaining engine efficiency and performance.

Integration with the Cylinder Top Level Assembly Head

In engines with a cylinder top level assembly head, the intake valve is a fundamental part of this complex system. The assembly head often includes components like the valve train, which consists of the camshaft, lifters, pushrods (in pushrod engines), and rocker arms. The intake valve’s operation is directly influenced by these components, as they control the timing and duration of the valve’s opening and closing. This synchronization is essential for optimal engine operation, affecting both power output and fuel efficiency.

Coordination with the Injector

The intake valve’s function is closely tied to the operation of the injector. As the intake valve opens, the injector sprays the fuel into the incoming air stream, creating the air-fuel mixture. The timing of the injector’s fuel delivery must be meticulously coordinated with the intake valve’s opening to ensure a homogeneous mixture. This precise coordination is fundamental for achieving the desired combustion characteristics, influencing both engine performance and emissions.

Conclusion

The Cummins 3696764 Intake Valve plays a pivotal role in the efficient operation of commercial truck engines. Its design, compatibility with various engine models, and integration with key engine systems underscore its importance in maintaining engine performance, fuel efficiency, and reliability. Regular maintenance and timely troubleshooting of common issues are essential for ensuring the longevity and optimal performance of this critical component.

-

Advanced Automotive Electricity and Electronics, Michael Klyde and Kirk VanGelder, Jones Bartlett Learning, 2010.

↩ -

Reducing Particulate Emissions in Gasoline Engines, Thorsten Boger, Willard Cutler, SAE International, 2018.

↩ -

Pistons and Engine Testing, Wolf-Henning Schneider, Springer Nature, 2016.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.