This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3802083 Intake Valve is a component designed for use in commercial trucks, playing a significant role in the engine’s operation. This valve is integral to the engine’s air intake system, facilitating the introduction of air into the combustion chamber, which is necessary for the engine’s operation 1.

Basic Concepts of Intake Valves

An intake valve is a component found in internal combustion engines. Its primary function is to allow air, and often a mixture of air and fuel, into the engine’s combustion chamber. The timing of the valve’s opening and closing is critical to the engine’s performance, as it directly affects the amount of air that enters the combustion chamber and, consequently, the power and efficiency of the engine 3.

Role of the 3802083 Intake Valve in Truck Operation

This Cummins part contributes to the operation of a truck by ensuring a consistent and adequate supply of air to the engine’s combustion chambers. This valve’s precise operation helps maintain engine efficiency and performance, allowing the truck to operate smoothly under various conditions. The valve’s design and material contribute to its ability to withstand the high temperatures and pressures within the engine, ensuring reliable operation over time 4.

Key Features of the 3802083 Intake Valve

This part is characterized by several key features that enhance its functionality. These include its material composition, which is designed to resist wear and corrosion, and its precise design, which ensures optimal performance. The valve is also engineered to operate under the high temperatures and pressures typical of diesel engines, contributing to its durability and reliability 2.

Benefits of Using the 3802083 Intake Valve

The use of this part is associated with several benefits. These include improved engine performance, as the valve ensures a consistent and adequate supply of air to the combustion chambers. The valve’s durable construction also contributes to its longevity, reducing the need for frequent replacements. Additionally, the valve’s reliable operation helps maintain engine efficiency, contributing to fuel savings over time 3.

Troubleshooting and Maintenance Suggestions

Common issues with this Cummins part may include wear, corrosion, or improper seating, which can affect engine performance. Regular inspection and maintenance can help identify and address these issues before they become significant problems. This may involve cleaning the valve, checking for wear or damage, and ensuring it is properly seated in the engine. Following the manufacturer’s recommended maintenance schedule can help ensure the valve’s optimal performance and longevity 4.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a leader in the diesel engine manufacturing industry. The company is committed to innovation and quality, continually striving to improve its products and services to meet the evolving needs of its customers.

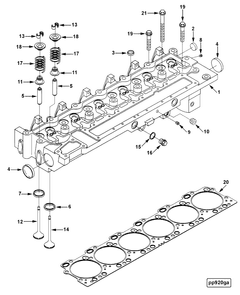

Components of Cummins Intake Valve Kit 3802083

Valve Spring

The valve spring is a critical component in the Cummins intake valve kit 3802083. It ensures that the intake valve returns to its closed position after being opened by the camshaft. The spring’s design allows it to withstand high temperatures and pressures, maintaining consistent valve operation throughout the engine’s lifespan.

Retainer

The retainer is designed to hold the valve spring in place, preventing it from dislodging during engine operation. It is typically made from a durable material that can withstand the high temperatures and pressures within the engine cylinder.

Locking Pin

The locking pin secures the valve spring and retainer in position on the valve stem. This component is essential for maintaining the integrity of the valve train, ensuring that the valve operates smoothly and efficiently.

Valve Stem Seal

The valve stem seal is responsible for preventing oil from leaking past the valve stem into the combustion chamber. This seal is crucial for maintaining engine performance and efficiency, as oil contamination in the combustion chamber can lead to decreased power output and increased emissions.

Shim

The shim is a small, thin piece of metal that is used to adjust the clearance between the valve and the camshaft. Proper valve clearance is essential for optimal engine performance, and the shim allows for precise adjustments to be made during installation or maintenance.

Valve Guide

The valve guide provides a smooth surface for the valve stem to move up and down within the cylinder head. It helps to maintain the proper alignment of the valve and reduces friction, contributing to the overall efficiency and longevity of the engine.

Valve Seat

The valve seat is the surface within the cylinder head where the valve makes contact when it is closed. It must be precisely machined to ensure a tight seal, preventing exhaust gases from leaking into the intake tract and compromising engine performance.

Gasket

The gasket is a thin, flexible material that is used to seal the various components within the intake valve kit. It ensures that there are no leaks between the valve, valve seat, and cylinder head, maintaining the integrity of the engine’s combustion process.

O-Ring

The O-ring is a circular, elastomeric seal that is used to prevent fluid leaks in various applications within the intake valve kit. It is typically found in areas where moving parts meet stationary components, such as around the valve stem or within the valve guide.

Spring Seat

The spring seat is a component that sits atop the valve spring, providing a stable platform for the spring to rest upon. It helps to distribute the force of the spring evenly across the valve, ensuring consistent valve operation and reducing the risk of valve failure.

Valve Collet

The valve collet is a metal component that is used to secure the valve stem within the valve guide. It helps to maintain the proper alignment of the valve and reduces the risk of valve stem deflection, contributing to the overall stability and performance of the engine.

Conclusion

In summary, the Cummins 3802083 Intake Valve plays a crucial role in the operation of commercial trucks by ensuring a consistent and adequate supply of air to the engine’s combustion chambers. Its key features, including durable material composition and precise design, contribute to its functionality and reliability. Regular maintenance and troubleshooting can help ensure the valve’s optimal performance and longevity, ultimately contributing to improved engine efficiency and fuel savings.

-

Libby Osgood, Gayla Cameron, and Emma Christensen, Engineering Mechanics: Statics (Creative Commons, 2024).

↩ -

Hans B. Pacejka, Tyre and Vehicle Dynamics (Butterworth-Heinemann, 2006).

↩ -

Douglas R Carroll, Energy Efficiency of Vehicles (SAE International, 2020).

↩ ↩ -

Andrew Brown Jr, Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles (National Academy of Sciences, 2010).

↩ ↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.