This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

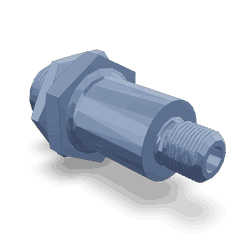

The Cummins 3864239 Check Valve is a critical component in commercial truck systems, designed to ensure unidirectional fluid flow and prevent backflow, which could lead to system inefficiencies or damage 3. This part is essential for maintaining the integrity and performance of various truck systems by regulating fluid flow.

Basic Concepts of Check Valves

Check valves are mechanical devices that allow fluid to flow through them in one direction only, automatically closing to prevent reverse flow 1. They are used in fluid systems to maintain pressure, prevent contamination, and protect equipment from damage due to backflow. Applications span across automotive, hydraulic, and pneumatic systems.

Role of the 3864239 Check Valve in Truck Operations

In commercial trucks, the 3864239 Check Valve ensures fluid flows in the intended direction within fuel, lubrication, or hydraulic systems 2. In the fuel system, it maintains consistent fuel pressure and prevents fuel from flowing back into the tank, which could cause engine performance issues. In lubrication systems, it ensures oil reaches all necessary components without backflow, maintaining optimal lubrication and reducing wear. In hydraulic systems, it helps maintain system pressure and efficiency by preventing hydraulic fluid from returning to the reservoir unintentionally.

Key Features

The 3864239 Check Valve features a spring-loaded disc or ball that opens under forward pressure and closes when the pressure reverses, effectively blocking backflow. Constructed from durable materials, it can withstand high pressures and temperatures, ensuring longevity and reliability. It is designed to operate efficiently under a range of pressure conditions, making it suitable for various applications within commercial trucks.

Benefits of Using the 3864239 Check Valve

Using the 3864239 Check Valve improves system efficiency by ensuring fluids flow in the correct direction, reducing the risk of system malfunctions 3. Its reliable operation enhances the overall reliability of the truck’s systems, leading to fewer breakdowns and maintenance requirements. The valve’s durable construction and efficient design contribute to its longevity, providing cost-effective performance over the vehicle’s lifespan.

Installation Considerations

When installing the 3864239 Check Valve, it is important to follow guidelines and best practices to ensure proper function. The valve should be installed in the correct orientation, with the arrow or marking indicating the direction of flow pointing towards the system it is protecting. Proper tools should be used to avoid damaging the valve or its connections. Preparatory steps may include cleaning the installation site and ensuring that all connections are tight and secure to prevent leaks.

Troubleshooting Common Issues

Common problems associated with check valves include leakage, failure to open or close properly, and blockages. Diagnosing these issues involves checking for proper installation, inspecting for damage or wear, and ensuring that the valve is not obstructed. Solutions may include re-orienting the valve, cleaning or replacing the valve if damaged, or addressing any obstructions in the system.

Maintenance Tips

Routine maintenance practices can help ensure the longevity and optimal performance of the 3864239 Check Valve. Regular inspections for signs of wear or damage, cleaning the valve to remove any buildup that could impede its function, and ensuring that it remains properly oriented and connected are all important maintenance steps. Following the manufacturer’s recommendations for maintenance intervals and procedures can help prevent issues and extend the valve’s service life.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. Its product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of commercial and industrial applications. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry.

Cummins Check Valve 3864239 Compatibility

The Cummins Check Valve part number 3864239 is designed to fit seamlessly within the engine systems of the 4B3.9 and 6B5.9 engines. This check valve ensures that fluid flows in the correct direction within the engine’s hydraulic or fuel systems, preventing backflow and maintaining system integrity.

For the 4B3.9 engine, the check valve is engineered to integrate smoothly with the engine’s hydraulic circuits, ensuring optimal performance and reliability. Similarly, in the 6B5.9 engine, the check valve is meticulously crafted to fit within the engine’s fuel delivery system, providing a critical function in maintaining the correct pressure and flow of fuel.

Both engines benefit from the precision engineering of the Cummins Check Valve 3864239, ensuring that it performs reliably under the demanding conditions of these high-performance engines.

Role of Part 3864239 Check Valve in Engine Systems

In the context of engine systems, particularly those involving turbochargers and their associated plumbing, the Part 3864239 Check Valve serves a significant function. This component is strategically placed within the turbocharger plumbing to regulate the flow of fluids or gases, ensuring they move in a single direction.

When integrated into the turbocharger system, the Check Valve prevents backflow, which can lead to inefficiencies or damage within the system. It allows the pressurized air from the turbocharger to flow towards the engine’s intake system while blocking any reverse flow that could disrupt the turbocharger’s operation or cause damage to other components.

In the plumbing of the turbocharger system, the Check Valve is often positioned near the connection points between the turbocharger and the engine’s intake manifold. This placement ensures that the boosted air pressure is maintained at optimal levels, enhancing the engine’s performance and efficiency.

Furthermore, the Check Valve contributes to the overall reliability of the turbocharger system by protecting sensitive components from potential damage caused by reverse flow. This protection is essential for maintaining the longevity and performance of the turbocharger and the engine as a whole.

Conclusion

The Cummins 3864239 Check Valve is a vital component in commercial truck systems, ensuring unidirectional fluid flow and preventing backflow. Its reliable operation enhances system efficiency and reliability, contributing to the overall performance and longevity of the truck’s systems. Proper installation, maintenance, and troubleshooting are essential for maximizing the benefits of this part.

-

Hilgers, M. (2023). Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature.

↩ -

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.