This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3871372 Check Valve is a component designed for use in commercial truck operations. Its purpose is to regulate the flow of fluids within the truck’s systems, ensuring that fluid moves in the intended direction and preventing backflow. This valve is significant in maintaining the efficiency and reliability of truck operations by contributing to the proper functioning of the fuel and lubrication systems.

Basic Concepts of Check Valves

A check valve, also known as a non-return valve, is a mechanical device that allows fluid to flow through it in only one direction. It operates by using a mechanism that opens to permit forward flow and closes to prevent reverse flow. Check valves are commonly used in various fluid systems to maintain pressure, prevent contamination, and ensure the correct operation of equipment 1.

Purpose of the 3871372 Check Valve in Truck Operations

The Cummins 3871372 Check Valve plays a specific role in the operation of commercial trucks by regulating the flow of fluids within the fuel and lubrication systems. In the fuel system, it helps maintain consistent fuel pressure and prevents fuel from flowing back into the tank, which could lead to engine performance issues. In the lubrication system, it ensures that oil flows to critical components, reducing the risk of wear and tear.

Key Features

The Cummins 3871372 Check Valve is characterized by its robust design and the materials used in its construction. It is built to withstand the demanding conditions of commercial truck operations. The valve features a durable housing and a precision-machined internal mechanism that ensures reliable operation. Its design includes features that enhance performance and durability, such as corrosion-resistant materials and a tight seal to prevent leaks.

Benefits of Using the 3871372 Check Valve

Utilizing the Cummins 3871372 Check Valve offers several advantages. It contributes to improved system efficiency by ensuring that fluids flow in the correct direction, reducing the likelihood of system failures. The valve’s design and materials result in reduced maintenance needs, as it is built to operate reliably under harsh conditions. Additionally, its integration into truck systems enhances overall reliability, supporting consistent truck performance.

Installation and Integration

Proper installation and integration of the Cummins 3871372 Check Valve into truck systems are vital for optimal performance. Installation guidelines recommend ensuring that the valve is correctly oriented to allow for forward fluid flow. It is also important to verify that the valve is compatible with the specific truck model and system requirements. Following manufacturer recommendations for installation ensures that the valve functions as intended.

Troubleshooting Common Issues

Common problems associated with check valves include leaks, blockages, and failure to open or close properly. These issues can be caused by debris in the fluid, wear on the valve components, or incorrect installation. Troubleshooting steps may involve inspecting the valve for signs of damage, cleaning or replacing components as necessary, and ensuring that the valve is installed correctly.

Maintenance Tips

Regular maintenance practices are essential for ensuring the longevity and efficient operation of the Cummins 3871372 Check Valve. Maintenance tips include periodic inspection for signs of wear or damage, cleaning the valve to remove any debris that may affect its operation, and following the manufacturer’s recommended maintenance schedule. These practices help maintain the valve’s performance and extend its service life.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves commercial, industrial, and automotive markets. The company is known for its commitment to providing reliable and efficient power solutions, supported by a comprehensive range of products and services designed to meet the needs of its customers 2.

Cummins Check Valve 3871372 Compatibility

The Cummins Check Valve 3871372 is a critical component designed to ensure the smooth operation of various Cummins engines. This part is engineered to maintain the integrity of the engine’s hydraulic and fuel systems by preventing backflow, which can cause significant damage and inefficiencies.

ISX CM570

The ISX CM570 engine is a high-performance, heavy-duty diesel engine known for its robust design and reliability. The Check Valve 3871372 is specifically tailored to fit within the intricate hydraulic and fuel systems of the ISX CM570, ensuring optimal performance and longevity. Its placement is crucial in maintaining the pressure and flow characteristics necessary for the engine’s operation.

Cummins Engines Group

For engines within the Cummins Engines Group, the Check Valve 3871372 is a versatile component that can be integrated into various models. Its design allows it to function seamlessly across different engine configurations, providing a consistent level of performance and reliability. This compatibility is essential for maintaining the efficiency and durability of the engines in this group.

Installation and Maintenance

Proper installation of the Check Valve 3871372 is critical to ensure it functions as intended. Technicians should follow the manufacturer’s guidelines for installation, which typically include precise alignment and secure mounting. Regular maintenance checks should be performed to verify the valve’s condition and ensure it is free from obstructions or damage. This proactive approach helps prevent unexpected failures and extends the lifespan of the engine components.

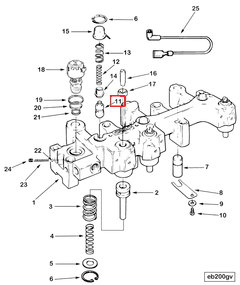

Role of Part 3871372 Check Valve in Engine Systems

The Part 3871372 Check Valve is an essential component in the regulation and maintenance of fluid dynamics within various engine systems. Its primary function is to allow fluid to flow in one direction while preventing reverse flow, ensuring the system operates efficiently and safely.

Integration with Engine Components

Engine Brake Lever

The check valve works in conjunction with the Engine Brake Lever to manage the hydraulic pressure that engages the engine braking system. By allowing pressurized fluid to reach the brake mechanism while preventing backflow, it ensures that the brake lever operates smoothly and effectively, enhancing the control and safety of the engine braking process.

Engine Brake Tune-Up Kit

When included in an Engine Brake Tune-Up Kit, the check valve plays a vital role in maintaining the integrity of the hydraulic system. It ensures that the fluids used for tuning and calibration flow correctly through the system, preventing any contamination or pressure loss that could affect the performance of the engine brake.

Rocker Lever

In systems utilizing a Rocker Lever, the check valve helps maintain consistent pressure and flow. This is particularly important in applications where the rocker lever is used to modulate fluid pressure, such as in variable valve timing systems. The check valve ensures that the pressure applied to the rocker lever is stable, allowing for precise control over valve operation.

Rocker Lever Top-Level Assembly

The Rocker Lever Top-Level Assembly often relies on hydraulic pressure to function correctly. The check valve ensures that the hydraulic fluid reaches the assembly without any reverse flow, which could cause instability or malfunction. This consistent fluid flow is essential for the accurate operation of the rocker lever within the top-level assembly, contributing to the overall efficiency and reliability of the engine system.

Conclusion

The Cummins 3871372 Check Valve is a vital component in the operation of commercial trucks and various engine systems. Its role in regulating fluid flow, preventing backflow, and ensuring system efficiency and reliability cannot be overstated. Proper installation, maintenance, and understanding of its function are crucial for maximizing the performance and longevity of the systems it serves.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.