This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3874153 Check Valve is a specialized component designed for use in commercial trucks. Its primary function is to regulate the flow of fluids within the truck’s systems, ensuring that fluid moves in the intended direction and preventing backflow. This part is integral to maintaining the efficiency and reliability of the truck’s fluid systems, contributing to overall vehicle performance.

Basic Concepts of Check Valves

A check valve, also known as a non-return valve, is a mechanical device that allows fluid to flow through it in only one direction. It operates by using a mechanism that opens to permit forward flow and closes to prevent reverse flow. Check valves are commonly used in various fluid systems, including water, air, and fuel systems, to ensure that fluid dynamics are maintained as designed 1.

Purpose of the 3874153 Check Valve in Truck Operations

In the context of commercial trucks, the 3874153 Check Valve plays a significant role in the operation of the truck’s fluid systems. It is typically installed in the fuel or coolant system to ensure that fluid flows in the correct direction, preventing backflow that could lead to system inefficiencies or damage. By maintaining proper fluid flow, the check valve contributes to the stable operation of the truck’s engine and other fluid-dependent systems.

Key Features

The Cummins 3874153 Check Valve is characterized by its robust design and the use of high-quality materials, which enhance its durability and performance. Key features include a precision-machined body, a resilient seat material that ensures a tight seal, and a spring-loaded mechanism that responds quickly to changes in fluid flow. These attributes contribute to the valve’s reliability and efficiency in demanding truck applications.

Benefits of Using the 3874153 Check Valve

Incorporating the 3874153 Check Valve into truck systems offers several advantages. It enhances system efficiency by ensuring unidirectional fluid flow, which can lead to improved engine performance and fuel economy. The valve’s reliable operation reduces the risk of system failures due to backflow, contributing to increased vehicle uptime. Additionally, its design facilitates easier maintenance and longer service intervals, offering cost benefits over time.

Installation Considerations

Proper installation of the 3874153 Check Valve is crucial for its effective operation. It should be installed in the correct orientation, with the arrow or marking on the valve indicating the direction of flow. Compatibility with the truck’s fluid system and integration with other components must be ensured to avoid issues such as leaks or inefficient fluid flow. Following manufacturer guidelines for installation will help maximize the valve’s performance and longevity.

Troubleshooting Common Issues

Common problems associated with check valves include leakage, failure to open or close properly, and obstructions within the valve. These issues can arise from debris in the fluid, wear and tear on the valve components, or incorrect installation. Troubleshooting steps may involve inspecting the valve for damage, cleaning or replacing components as necessary, and ensuring the valve is correctly oriented and integrated within the system.

Maintenance Tips

To ensure the longevity and optimal performance of the 3874153 Check Valve, regular maintenance is recommended. This includes periodic inspection for signs of wear or damage, cleaning the valve to remove any debris that may affect its operation, and testing its function to ensure it opens and closes as intended. Replacement should be considered if the valve shows significant wear or if its performance declines, to prevent potential system issues.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s extensive product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle applications.

Cummins Check Valve 3874153 Compatibility

The Cummins Check Valve 3874153 is a critical component designed to ensure unidirectional flow in various engine systems. This valve is engineered to fit seamlessly with specific Cummins engines, providing reliable performance and preventing backflow.

K19 Engine

The Cummins Check Valve 3874153 is specifically designed to integrate with the K19 engine. This engine is known for its robust construction and efficiency, making it a popular choice in various applications. The check valve ensures that the fluid flow within the engine’s system remains unidirectional, which is crucial for maintaining optimal engine performance and longevity.

V28 Engine

Similarly, the Cummins Check Valve 3874153 is also compatible with the V28 engine. The V28 engine is another model in Cummins’ lineup, recognized for its power and reliability. The check valve’s role in this engine is to prevent any reverse flow, which could potentially damage the engine or reduce its efficiency. By ensuring that the fluid flows in the correct direction, the check valve contributes to the overall reliability and efficiency of the V28 engine.

Group Compatibility

While the Cummins Check Valve 3874153 is explicitly designed for the K19 and V28 engines, it is also compatible with other engines within the same group. This compatibility ensures that the check valve can be used across multiple models without any modifications, providing a versatile solution for maintaining fluid flow integrity in Cummins engines.

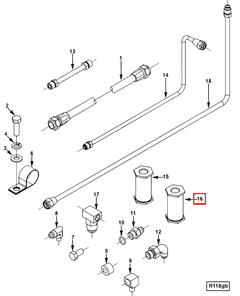

Role of Part 3874153 Check Valve in Engine Systems

The part 3874153 Check Valve is an integral component in the fuel system of engine systems, ensuring the unidirectional flow of fuel. This check valve is strategically positioned within the fuel plumbing to prevent fuel backflow, which could otherwise lead to inefficient engine performance or fuel system damage.

In the context of fuel supply plumbing, the check valve works in conjunction with the fuel supply check valve to maintain consistent fuel pressure. This is particularly important during engine start-up, where the primer system relies on stable fuel pressure to ensure smooth ignition. The check valve helps in this process by preventing any reverse flow that might occur when the pump is not actively pushing fuel through the system.

Furthermore, the check valve is essential in the fuel transfer system. It ensures that fuel moves from the fuel tank to the fuel supply lines without any interruptions or reversals. This is vital for maintaining the integrity of the fuel delivery system, especially under varying engine loads and operational conditions.

The integration of the check valve within the accessories G.T. starting system enhances the reliability of the engine start-up process. By ensuring that fuel is consistently available and under the correct pressure, the check valve supports the efficient operation of the starting system, reducing the likelihood of start-up issues.

Conclusion

The Cummins 3874153 Check Valve plays a significant role in maintaining the efficiency and reliability of commercial truck fluid systems. Its robust design, key features, and compatibility with various Cummins engines make it a critical component for ensuring unidirectional fluid flow. Regular maintenance and proper installation are essential for maximizing the valve’s performance and longevity, contributing to the overall performance and uptime of commercial trucks.

-

Hilgers, Michael. Vocational Vehicles and Applications. Springer Nature, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.