This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3926558 Check Valve is a specialized component designed for use in commercial truck systems. Its purpose is to ensure the unidirectional flow of fluids within the system, preventing backflow that could lead to inefficiencies or damage. This valve is integral to maintaining the optimal operation of various truck systems, including fuel, lubrication, and hydraulic circuits.

Basic Concepts of Check Valves

A check valve, also known as a non-return valve, is a mechanical device that allows fluid to flow through it in only one direction. It operates using a mechanism that opens when fluid flows in the correct direction and closes when the flow attempts to reverse. This functionality is vital in fluid systems to prevent backflow, which can cause contamination, system inefficiencies, and potential damage to other components. Check valves find applications in a wide range of systems, including water, gas, and oil systems, where maintaining the direction of flow is crucial 1.

Purpose of the Cummins 3926558 Check Valve

The Cummins 3926558 Check Valve plays a specific role in the operation of commercial trucks by ensuring the unidirectional flow of fluids within the system. In the fuel system, it helps maintain consistent fuel pressure and prevents fuel from flowing back into the supply line, which could lead to engine performance issues. Within the lubrication system, it ensures that oil flows in the correct direction, protecting critical engine components from wear and damage. In hydraulic systems, the valve maintains system pressure and prevents hydraulic fluid from returning to the reservoir, ensuring efficient operation of hydraulic actuators and controls.

Key Features

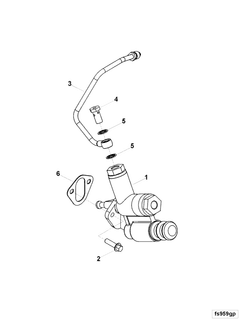

The Cummins 3926558 Check Valve is constructed from durable materials, ensuring longevity and reliability in demanding commercial truck environments. Its design includes a spring-loaded mechanism that opens and closes in response to fluid flow, providing precise control over the direction of flow. Unique attributes of this valve include its compact size, which allows for easy integration into existing systems, and its robust construction, which enhances performance and durability.

Benefits

The Cummins 3926558 Check Valve offers several advantages, including improved system efficiency by ensuring unidirectional fluid flow, which reduces the risk of contamination and system inefficiencies. Its reliable operation contributes to the overall reliability of the truck’s systems, reducing the likelihood of unexpected downtime. Additionally, by preventing backflow, the valve can contribute to cost savings by prolonging the lifespan of system components and reducing the need for frequent maintenance 2.

Installation Considerations

When installing the Cummins 3926558 Check Valve, it is important to follow guidelines and best practices to ensure proper operation. The valve should be oriented correctly, with the flow arrow indicating the direction of fluid flow. Required tools for installation may include wrenches and sealant to ensure a secure and leak-free connection. Integration within existing systems should be carefully planned to avoid disrupting other components and to ensure seamless operation.

Troubleshooting Common Issues

Typical problems associated with check valves include leakage, failure to open or close properly, and blockages. Diagnosing these issues may involve checking for proper orientation, inspecting the valve for damage or wear, and ensuring that there are no obstructions in the fluid path. Recommended solutions or adjustments may include re-orienting the valve, cleaning or replacing the valve, or addressing any blockages in the system.

Maintenance Tips

Routine maintenance practices are crucial for ensuring the longevity and optimal performance of the Cummins 3926558 Check Valve. Inspection intervals should be established based on the operating conditions and the manufacturer’s recommendations. Cleaning procedures may involve flushing the valve with a compatible solvent to remove any buildup or contaminants. Regular maintenance helps prevent issues and ensures the valve continues to operate efficiently.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial and industrial applications. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry 3.

Role of Part 3926558 Check Valve in Engine Systems

In the context of engine systems, the Part 3926558 Check Valve is integral to maintaining the efficiency and reliability of fuel delivery. When integrated into the Service Parts Lift Pump Kit, this check valve ensures that fuel flows in a single direction, preventing any backflow that could compromise the system’s performance.

Integration with Lift Pump Kit

Within the Service Parts Lift Pump Kit, the check valve is positioned to regulate the fuel flow from the tank to the high-pressure fuel pump. This setup is essential for maintaining consistent fuel pressure, which is vital for the engine’s combustion process. The check valve allows fuel to be drawn into the pump while preventing it from flowing back into the tank, ensuring a steady supply of fuel under pressure.

Enhancing System Performance

The presence of the check valve in the lift pump kit contributes to the overall performance of the engine system. By ensuring unidirectional fuel flow, it helps in reducing the workload on the high-pressure pump, leading to improved efficiency and longevity of the pump components. Additionally, it aids in maintaining a stable fuel pressure, which is necessary for optimal engine operation.

Supporting Fuel System Integrity

Incorporating the check valve into the lift pump kit also supports the integrity of the fuel system. It acts as a barrier against potential contaminants that might be present in the fuel tank, preventing them from entering the high-pressure fuel lines. This protective function is essential for preserving the cleanliness of the fuel system, which is paramount for the engine’s health and performance.

Facilitating Maintenance and Diagnostics

The check valve’s role in the lift pump kit also extends to facilitating maintenance and diagnostics. By ensuring proper fuel flow, it helps in identifying issues related to fuel delivery more accurately. If there are inconsistencies in engine performance, the check valve’s functionality can be assessed as part of the diagnostic process, aiding in the timely identification and resolution of potential problems.

Conclusion

The Cummins 3926558 Check Valve is a key component in the Service Parts Lift Pump Kit, playing a significant role in enhancing the efficiency, performance, and integrity of the engine’s fuel system. Its reliable operation ensures unidirectional fluid flow, contributing to the overall reliability and efficiency of commercial truck systems.

-

Hilgers, Michael. The Diesel Engine Second Edition. Springer Nature, 2023.

↩ -

Arora, Shashank, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi. Heavyduty Electric Vehicles: From Concept to Reality. Elsevier, 2021.

↩ -

Minaker, Bruce P. Fundamentals of Vehicle Dynamics and Modelling. John Wiley & Sons, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.