This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

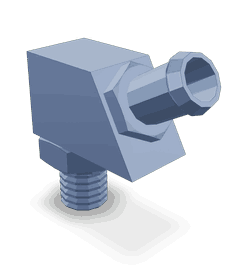

The Cummins 3932282 Check Valve is a component designed for use in commercial trucks. It ensures the proper direction of fluid flow and maintains system integrity within the truck’s fluid systems. Understanding its purpose and operation is essential for maintaining the efficiency and reliability of the truck.

Basic Concepts of Check Valves

A check valve, also known as a non-return valve, allows fluid to flow through it in only one direction. It operates by opening when the fluid flows in the correct direction and closing when the flow attempts to reverse. This mechanism is vital in fluid systems to prevent backflow, which can cause damage or inefficiency 1.

Purpose of the Cummins 3932282 Check Valve

This Cummins part ensures that fluid flows in the correct direction within the truck’s fluid systems. This is crucial in systems where backflow could lead to contamination, reduced efficiency, or damage to other components. By preventing reverse flow, the check valve helps maintain the integrity and performance of the truck’s fluid systems.

Key Features

The Cummins 3932282 Check Valve features a spring-loaded disc that opens and closes to allow or prevent fluid flow. It is constructed from durable materials that can withstand the pressures and temperatures encountered in commercial truck applications. Additionally, it may feature unique characteristics such as a corrosion-resistant coating or a design that minimizes pressure drop, differentiating it from other check valves.

Benefits

The advantages of the Cummins 3932282 Check Valve include improved system efficiency, enhanced reliability, and increased longevity. By ensuring proper fluid flow direction, the valve helps maintain system performance and reduce the risk of damage to other components. Its durable construction and design features contribute to its reliability and longevity, making it a valuable component in commercial truck fluid systems.

Installation Considerations

When installing the Cummins 3932282 Check Valve, it is important to follow guidelines and best practices to ensure proper integration within the truck’s system. This includes orienting the valve correctly to allow for the intended direction of fluid flow and ensuring a secure fit within the system. Proper installation is key to achieving optimal performance and longevity of the valve.

Troubleshooting and Maintenance

Common issues that may arise with the Cummins 3932282 Check Valve include blockages, leaks, or failure of the valve to open or close properly. Diagnosing these problems may involve checking for obstructions, inspecting seals and connections, and testing the valve’s operation. Regular maintenance, such as cleaning and inspecting the valve, can help ensure optimal performance and prevent issues from arising.

Performance in Various Conditions

The Cummins 3932282 Check Valve is designed to perform under a range of operating conditions, including varying temperatures, pressures, and fluid types. Its robust construction and design features allow it to maintain functionality and reliability in these diverse conditions, contributing to the overall performance and efficiency of the truck’s fluid systems.

Comparison with Other Check Valves

A comparative analysis of the Cummins 3932282 Check Valve with other check valves available in the market reveals differences in design, performance, and application. While all check valves serve the basic function of preventing backflow, the Cummins valve may offer specific advantages in terms of durability, efficiency, or compatibility with certain fluid systems, making it a preferred choice for commercial truck applications 2.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. The company’s commitment to quality and customer satisfaction is reflected in its products, including the Cummins 3932282 Check Valve 3.

Cummins Check Valve 3932282 Compatibility

The Cummins Check Valve 3932282 is designed to fit seamlessly within a range of Cummins engine models. This part is integral to maintaining the operational efficiency of these engines by ensuring that fluid flows in the correct direction, preventing backflow and maintaining system integrity.

Engine Compatibility

6B5.9 The 6B5.9 engine benefits from the precise functionality of the 3932282 Check Valve. This part ensures that the engine operates smoothly by controlling the flow of fluids, which is crucial for maintaining optimal performance.

ISB CM550 In the ISB CM550 engine, the 3932282 Check Valve plays a critical role in the engine’s hydraulic system. Its design ensures that the fluid flow is unidirectional, which is essential for the engine’s overall efficiency and longevity.

ISC CM554 and ISL CM554 Both the ISC CM554 and ISL CM554 engines are equipped with the 3932282 Check Valve to manage fluid dynamics effectively. This part is crucial in these engines, as it helps maintain the correct pressure and flow rates necessary for peak performance.

QSC8.3 CM554 and QSL9 CM554 The QSC8.3 CM554 and QSL9 CM554 engines also rely on the 3932282 Check Valve for proper fluid management. This component ensures that the engines run smoothly by preventing backflow, which can lead to inefficiencies and potential damage.

The 3932282 Check Valve is a versatile component that is essential for the proper functioning of these Cummins engines. Its design allows it to fit seamlessly into the hydraulic systems of the listed engines, ensuring that fluid flows in the correct direction and maintaining the engine’s overall efficiency.

Role of Part 3932282 Check Valve in Engine Systems

Air Compressor Systems

In air compressor systems, the 3932282 Check Valve is instrumental in maintaining the integrity of the compressed air flow. It is typically installed between the compressor and the storage tank. The valve allows air to flow into the tank while preventing backflow, which ensures that the compressed air remains at the desired pressure. This function is essential for the efficient operation of the compressor, as it prevents the loss of compressed air and reduces the workload on the compressor by maintaining consistent pressure levels.

Vacuum Pump Systems

When integrated into vacuum pump systems, the 3932282 Check Valve serves to maintain the vacuum level by preventing the backflow of air into the system. It is usually placed between the vacuum pump and the process equipment. The valve ensures that once a vacuum is created, it is sustained, allowing the pump to operate efficiently without having to constantly re-establish the vacuum. This is particularly important in applications where a consistent vacuum level is required for processes such as filtration, evaporation, or degassing.

Conclusion

The Cummins 3932282 Check Valve is a critical component in maintaining the efficiency and reliability of commercial truck fluid systems. Its design, durability, and compatibility with various Cummins engine models make it an essential part for ensuring proper fluid flow direction and system integrity. Proper installation, regular maintenance, and understanding its role in different engine systems are key to maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.