This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

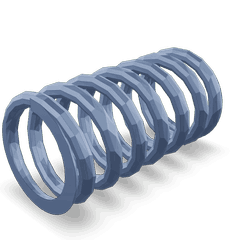

The Cummins 3932453 Valve Spring is a critical component designed for use in heavy-duty truck engines. Its primary function is to ensure the proper operation of the engine’s valve system by maintaining valve seating and timing. This spring plays a significant role in the efficient and reliable operation of the engine, contributing to overall performance and longevity.

Basic Concepts of Valve Springs

Valve springs are mechanical components found in internal combustion engines. Their general function is to keep the valves in contact with their seats when the engine is not in the valve opening phase. This ensures that the valves close properly and maintain the seal within the combustion chamber, which is vital for engine efficiency and performance. The design and quality of valve springs directly influence engine operation, affecting factors such as power output, fuel efficiency, and durability 1.

Role of the 3932453 Valve Spring in Truck Operation

The Cummins 3932453 Valve Spring is specifically engineered to operate within the demanding environment of heavy-duty truck engines. It interacts with other components such as valves and camshafts to ensure precise valve timing and seating. This spring’s design allows it to withstand the high stresses and temperatures encountered in truck engines, contributing to consistent engine performance under various operating conditions 2.

Key Features of the 3932453 Valve Spring

The Cummins 3932453 Valve Spring incorporates several unique features that enhance its performance and durability. Its design includes a specific coil configuration that provides the necessary spring rate for heavy-duty applications. The materials used in its construction are chosen for their strength and resistance to heat and wear. Additionally, technological advancements in manufacturing processes ensure that the spring meets the high standards required for heavy-duty truck engines 3.

Benefits of Using the 3932453 Valve Spring

Utilizing the Cummins 3932453 Valve Spring offers several advantages. It contributes to improved engine performance by ensuring reliable valve operation. The spring’s durability and resistance to wear enhance the engine’s longevity, reducing the need for frequent replacements. Furthermore, its reliable operation supports the overall reliability of the truck, minimizing downtime and maintenance costs.

Installation and Maintenance

Proper installation of the Cummins 3932453 Valve Spring is crucial for optimal performance. Specific procedures and tools may be required to ensure the spring is correctly positioned and tensioned. Regular maintenance, including inspection for signs of wear or damage, is recommended to ensure the spring continues to function effectively. Following manufacturer guidelines for maintenance can help extend the life of the valve spring and maintain engine performance.

Troubleshooting Common Issues

Common problems associated with valve springs, such as spring failure or valve train noise, can arise due to various factors including wear, improper installation, or engine stress. Troubleshooting these issues involves a systematic approach to diagnose the root cause. This may include inspecting the spring for physical damage, checking the valve train components for wear, and ensuring proper installation. Addressing these issues promptly can prevent further engine damage and maintain optimal performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industry. The company’s product range includes a variety of engines and components designed to meet the demanding requirements of commercial vehicles, contributing to the efficiency and performance of the transportation sector.

Compatibility with Cummins Engines

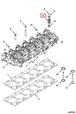

The Valve Spring part 3932453, manufactured by Cummins, is designed to be compatible with several of their engine models. This part is integral to the engine’s valve train system, ensuring the proper operation of the engine’s valves.

For the 4B3.9 and QSB3.9 30 CM550 engines, the Valve Spring part 3932453 is engineered to meet the specific requirements of these engines, providing reliable performance and durability.

Similarly, for the 6B5.9 and QSB5.9 30 CM550 engines, this valve spring is tailored to fit the unique design and operational parameters of these engines, ensuring optimal valve operation and engine efficiency.

The B4.5 and B6.7S engines also benefit from the use of the Valve Spring part 3932453. Cummins has designed this part to integrate seamlessly with these engines, contributing to their overall performance and longevity.

Lastly, the ISBE CM800 engine incorporates the Valve Spring part 3932453, which is specifically crafted to align with the engine’s design and operational needs, ensuring smooth and efficient valve operation.

Role of Part 3932453 Valve Spring in Engine Systems

The 3932453 Valve Spring is a critical component in the orchestration of various engine systems, ensuring the seamless operation of the internal combustion process. Positioned within the cylinder head, this valve spring works in tandem with other components to maintain the precise timing and efficiency of engine functions.

Interaction with the Cylinder Head

The cylinder head houses the valve spring, where it plays a pivotal role in controlling the opening and closing of the valves. This action is synchronized with the movement of the piston within the cylinder, allowing for the intake of air and fuel and the expulsion of exhaust gases. The valve spring’s ability to return the valve to its closed position after being opened by the camshaft is fundamental to the engine’s operation.

Coordination with the Fuel Supply Tube

As the valve spring ensures the valves operate correctly, the fuel supply tube delivers the necessary fuel to the combustion chamber. The timing of valve operation, governed by the valve spring, must be impeccably coordinated with the fuel delivery to optimize combustion efficiency and power output.

Integration with the Engine Control Module (ECM)

The Engine Control Module (ECM) monitors and adjusts various engine parameters in real-time. The valve spring’s consistent performance is vital for the ECM to accurately control ignition timing, fuel injection, and other critical functions. Any inconsistency in valve spring operation could lead to misfiring, reduced efficiency, or even engine damage, highlighting the importance of this component in the ECM’s control strategy.

Relationship with the Nef Cylinder

In engines equipped with a Nef cylinder, the valve spring’s role becomes even more pronounced. The Nef cylinder, designed for enhanced efficiency and power, relies on the valve spring to maintain the high-performance standards expected. The spring’s durability and precision are essential for the Nef cylinder to operate within its designed parameters, contributing to the engine’s overall performance and longevity.

Influence on Plumbing and Engine Systems

Beyond direct engine components, the valve spring indirectly affects the engine’s plumbing systems, including coolant and oil circulation. Efficient valve operation ensures the engine runs at optimal temperatures, which is crucial for the longevity and efficiency of the engine’s plumbing systems. Proper valve spring function helps maintain the engine’s thermal balance, preventing overheating and ensuring consistent oil pressure for lubrication.

Conclusion

In summary, the 3932453 Valve Spring is a linchpin in the complex interplay of engine components, from the cylinder head to the ECM, and beyond. Its role in ensuring the precise and reliable operation of engine valves underpins the efficiency, performance, and durability of the entire engine system.

-

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013.

↩ -

Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition, Robert Bosch GmbH, Springer Vieweg, 2007.

↩ -

Heavy-Duty Wheeled Vehicles, Haoran Hu, Rudy Smaling, and Simon Baseley, SAE International, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.