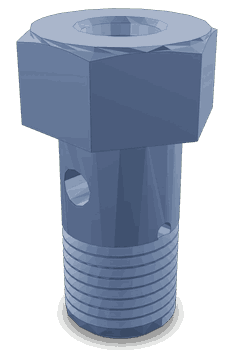

3941156

Check Valve

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3941156 Check Valve is a component designed for use in commercial trucks. It ensures the proper direction of fluid flow and maintains system integrity within the truck’s fluid systems. Understanding its purpose and operation is essential for maintaining the efficiency and reliability of commercial vehicles.

Basic Concepts of Check Valves

A check valve, also known as a non-return valve, is a mechanical device that allows fluid to flow through it in only one direction. It operates by using a movable element, such as a flap or a ball, that opens to permit forward flow and closes to prevent reverse flow. Check valves are commonly used in fluid systems to prevent backflow, which can cause system damage or inefficiency 1.

Purpose of the Cummins 3941156 Check Valve

This Cummins part plays a role in the truck’s fluid systems by ensuring that fluid flows in the intended direction. This is particularly important in systems where backflow could lead to contamination, loss of pressure, or other operational issues. By preventing reverse flow, the valve helps maintain the integrity and efficiency of the system 2.

Key Features

The Cummins 3941156 Check Valve is characterized by several design elements and materials that enhance its performance. It is constructed from durable materials to withstand the pressures and temperatures encountered in commercial truck applications. The valve’s design includes a precise sealing mechanism that ensures effective prevention of backflow, and it is engineered to operate reliably under a range of conditions.

Benefits

The use of the Cummins 3941156 Check Valve in a truck’s system can lead to improved efficiency and reliability. By preventing backflow, the valve helps to maintain system pressure and reduce the risk of contamination. This can result in fewer system failures and lower maintenance costs over time. Additionally, the valve’s durable construction contributes to its longevity, providing cost-saving advantages.

Installation and Integration

Proper installation of the Cummins 3941156 Check Valve is important for its effective operation. It should be installed in the correct orientation to ensure that it allows flow in the desired direction and prevents backflow. Integration into the truck’s system may require attention to compatibility with other components and adherence to manufacturer guidelines to ensure optimal performance.

Troubleshooting and Maintenance

Common issues with check valves can include leakage, failure to open or close properly, or blockages. Regular maintenance, such as inspection for wear and cleaning, can help prevent these issues. If problems arise, troubleshooting may involve checking the valve’s orientation, inspecting the sealing mechanism, and ensuring that there are no obstructions in the fluid path.

Common Applications

The Cummins 3941156 Check Valve is typically used in various fluid systems within commercial trucks, including fuel, hydraulic, and lubrication systems. Its application is widespread across different types of trucks, where maintaining the direction of fluid flow is important for system performance and longevity.

Safety Considerations

When working with the Cummins 3941156 Check Valve, it is important to follow safety procedures. This includes ensuring that the system is depressurized before beginning any work, using appropriate personal protective equipment, and adhering to manufacturer guidelines for installation and maintenance to prevent accidents and ensure safe operation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins plays a significant role in the commercial truck industry, providing components and systems that contribute to the efficiency, reliability, and performance of commercial vehicles 3.

Role of Part 3941156 Check Valve in Engine Systems

The Cummins 3941156 Check Valve is an essential component in the fuel and plumbing systems of an engine. It is strategically positioned to regulate the flow of fuel, ensuring that it moves in one direction only. This unidirectional flow is vital for maintaining consistent fuel pressure and preventing backflow, which could lead to engine inefficiencies or damage.

In the fuel system, the check valve works in conjunction with the fuel pump, fuel lines, and injectors. It ensures that the fuel, once pressurized by the pump, does not return to the tank, thereby maintaining a steady supply to the injectors. This consistent pressure is necessary for the injectors to atomize the fuel properly, leading to efficient combustion and optimal engine performance.

Within the plumbing system, the check valve plays a similar role. It prevents the reverse flow of fluids, which could cause contamination or pressure drops. This is particularly important in systems where multiple fluids are used, such as in engines with both fuel and coolant systems. The check valve ensures that each fluid remains within its designated pathways, preventing cross-contamination and maintaining the integrity of the system.

Overall, the integration of the Cummins 3941156 Check Valve in these systems enhances the reliability and efficiency of the engine, ensuring that both fuel and plumbing systems operate seamlessly.

Conclusion

The Cummins 3941156 Check Valve is a critical component in maintaining the efficiency and reliability of commercial truck fluid systems. Its role in preventing backflow and ensuring proper fluid circulation is essential for the smooth operation of engines. Proper installation, regular maintenance, and adherence to safety procedures are key to maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.