This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

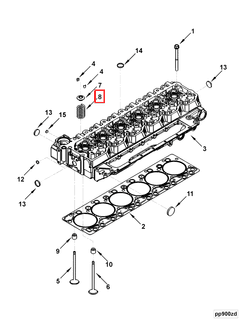

The Cummins 3942095 Valve Spring is a component designed to ensure the proper operation of valves in heavy-duty truck engines. Its role is significant in maintaining the efficiency and reliability of the engine, contributing to the overall performance of the vehicle 1.

Basic Concepts of Valve Springs

Valve springs are mechanical components that facilitate the opening and closing of engine valves. They operate by applying force to keep the valves seated against the camshaft’s lobes. When the camshaft rotates, it lifts the valve against the spring’s pressure, allowing air and fuel into the combustion chamber or expelling exhaust gases. The spring then returns the valve to its closed position once the camshaft lobe moves past 2.

Role of the 3942095 Valve Spring in Truck Operation

This Cummins part plays a specific role in the engine’s valve train by ensuring that the valves open and close at the correct times and with the appropriate force. This contributes to the engine’s performance and efficiency by maintaining proper valve timing and sealing, which are critical for optimal combustion and power output 1.

Key Features of the 3942095 Valve Spring

The Valve Spring is characterized by its design and construction, which include the use of high-quality materials to withstand the stresses of heavy-duty engine operation. The spring rate is calibrated to provide the necessary force for valve actuation, and it may feature unique characteristics such as a dual spring setup or specific coil configurations to enhance performance 3.

Benefits of Using the 3942095 Valve Spring

Utilizing this part offers several advantages, including improved engine reliability due to its robust construction. It also contributes to enhanced performance by ensuring precise valve operation, which can lead to better fuel efficiency and power output. Additionally, the spring’s design promotes longevity, reducing the need for frequent replacements 1.

Installation and Maintenance

Proper installation of 3942095 involves following specific torque specifications and alignment procedures to ensure it functions correctly within the engine. Regular maintenance, such as checking for wear and ensuring proper tension, is vital to maintain the spring’s performance and prevent issues such as valve float or failure 3.

Troubleshooting Common Issues

Common problems with valve springs, such as valve float or spring failure, can be identified through symptoms like engine misfires or reduced performance. Diagnosis may involve inspecting the spring for signs of wear or damage, and resolution could include replacing the spring or adjusting the valve train components 2.

Performance Enhancements

Upgrading to the 3942095 Valve Spring can contribute to performance enhancements in heavy-duty trucks. It may allow for increased horsepower and torque by supporting higher engine speeds and more aggressive camshaft profiles, which demand a valve spring capable of maintaining valve control under more strenuous conditions 1.

Cummins Corporation

Cummins Inc. is a well-established manufacturer in the heavy-duty truck industry, known for its wide range of products and strong reputation for quality and reliability. The company’s history is marked by innovation and a commitment to providing solutions that meet the demanding requirements of commercial and industrial applications 1.

Role of 3942095 Valve Spring in Engine Systems

In the orchestration of an engine’s operation, this part assumes a significant role, particularly within the cylinder head assembly. This component is instrumental in ensuring the proper function of the valve train, which is essential for the engine’s intake and exhaust processes.

The valve spring’s primary function is to maintain consistent valve seating. As the camshaft lobes open the valves, the valve spring ensures that they close promptly and securely once the cam lobe moves away. This action is vital for maintaining the engine’s compression and ensuring efficient combustion.

Moreover, the valve spring counteracts the centrifugal forces that arise as the engine’s RPM increases. Without adequate spring pressure, valves could float, leading to incomplete sealing and potential engine damage. The spring’s design allows it to absorb the energy from the valve’s motion and return it to keep the valve operating within its designed parameters 2.

In the cylinder head, the valve spring works in conjunction with other components such as the valve keepers, which secure the spring in place, and the valve stem, which transfers the spring’s force to the valve. The spring’s performance directly affects the durability and efficiency of the valve train, influencing the engine’s overall performance and longevity 3.

Understanding the interplay between the valve spring and the cylinder head components is essential for maintaining engine health. Proper installation and regular inspection of the valve spring are recommended to prevent issues such as valve train noise, reduced engine performance, or even catastrophic engine failure 3.

Conclusion

The 3942095 Valve Spring by Cummins is a critical component in the valve train system of heavy-duty truck engines. Its proper function ensures efficient valve operation, contributing to the engine’s performance, reliability, and longevity. Regular maintenance and proper installation are key to maximizing the benefits of this part.

-

TK Garrett, K Newton, W Steeds, The Motor Vehicle, Reed Educational and Professional Publishing Ltd, 2001.

↩ ↩ ↩ ↩ ↩ -

Harald Naunheimer, Bernd Bertsche, Joachim Ryborz, Wolfgang Novak, Automotive Transmissions Fundamentals Selection Design and Application, Springer Vieweg, 2011.

↩ ↩ ↩ -

Rob Thompson, Automotive Maintenance: Light Repair, Cengage Learning, 2019.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.