This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3957914 Valve Rotator is a component designed to enhance the operation of heavy-duty truck engines. Its purpose is to ensure the consistent and efficient functioning of engine valves, which are vital for the overall performance and longevity of the engine. By facilitating the even distribution of wear across valve faces, this valve rotator contributes to maintaining engine efficiency and reliability 1.

Basic Concepts of Valve Rotators

A valve rotator is a device installed within an engine’s valve train. Its function is to rotate the valves slightly with each cycle, ensuring that wear is distributed evenly across the valve face. This even distribution helps prevent localized wear and tear, which can lead to valve failure. The importance of valve rotators lies in their ability to maintain valve health, thereby enhancing engine performance and longevity 2.

Purpose of the Cummins 3957914 Valve Rotator

The Cummins 3957914 Valve Rotator plays a role in the operation of a truck engine by ensuring that the valves rotate slightly with each cycle. This rotation helps in the even distribution of wear across the valve faces, which in turn contributes to valve longevity and enhances engine efficiency. By reducing the risk of valve failure due to uneven wear, this component supports the consistent performance of the engine 3.

Key Features

The Cummins 3957914 Valve Rotator is characterized by its robust design and the use of high-quality materials. These features contribute to its durability and effectiveness in harsh operating conditions. The rotator is engineered to withstand the high temperatures and pressures present in heavy-duty truck engines, ensuring reliable performance over time. Additionally, its design allows for easy installation and maintenance, making it a practical choice for fleet operators 4.

Benefits of Using the Cummins 3957914 Valve Rotator

Utilizing the Cummins 3957914 Valve Rotator offers several advantages. It contributes to improved valve performance by ensuring even wear distribution. This results in reduced wear on valve faces, leading to enhanced engine reliability. Furthermore, the consistent operation of the valves supported by this rotator can contribute to better fuel efficiency and overall engine performance 5.

Installation Process

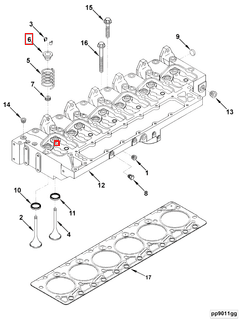

Installing the Cummins 3957914 Valve Rotator involves several steps. First, the engine must be prepared by ensuring it is clean and free of any debris. The existing valve components should be inspected and, if necessary, cleaned or replaced. The rotator is then positioned within the valve train, following the manufacturer’s guidelines for proper alignment and securing. Tools required for installation may include wrenches and socket sets, depending on the specific engine model 6.

Troubleshooting Common Issues

Common problems associated with valve rotators can include improper installation, leading to uneven valve rotation, or wear and tear on the rotator itself. To address these issues, it is important to conduct regular inspections of the valve train components. If uneven valve wear is observed, the installation of the rotator should be checked for correctness. Additionally, worn rotators may need to be replaced to ensure optimal valve operation 7.

Maintenance Tips

To ensure the optimal performance and longevity of the Cummins 3957914 Valve Rotator, regular maintenance is recommended. This includes periodic inspection of the valve train components for signs of wear or damage. Cleaning the rotator and its surrounding components can help prevent the buildup of debris, which may affect its operation. Following the manufacturer’s maintenance schedule will help in identifying any issues early and ensuring the continued efficient operation of the engine 8.

Performance Impact

The Cummins 3957914 Valve Rotator influences engine performance by contributing to the even wear of valve faces. This even wear supports consistent valve operation, which can lead to improved fuel efficiency and reduced emissions. Furthermore, by enhancing valve longevity, this component plays a role in maintaining the overall reliability and performance of the truck’s engine 9.

Compatibility with Cummins Engines

The Valve Rotator part 3957914, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. Specifically, this part is compatible with the 6B5.9, B5.9 GAS PLUS CM556, and QSB5.9G engines. For the 6B5.9 and B5.9 GAS PLUS CM556 engines, the Valve Rotator is engineered to ensure smooth and efficient operation of the valve mechanisms. Its precision design helps in maintaining optimal engine performance by reducing wear and tear on the valves. In the case of the QSB5.9G engine, the Valve Rotator part 3957914 is crucial for maintaining the integrity of the valve system. This engine variant relies on this component to ensure that the valves operate correctly, which is vital for the engine’s overall efficiency and longevity. The compatibility of this Valve Rotator across these engine models underscores its versatility and importance in Cummins’ engine lineup. Its design ensures that it can be integrated into different engine configurations while providing the necessary functionality to enhance engine performance 10.

Role of Part 3957914 Valve Rotator in Engine Systems

The Valve Rotator, identified by part number 3957914, is a component in the orchestration of an engine’s valve train system. It is designed to enhance the performance and longevity of the engine by ensuring uniform wear on the valve faces and seats. When integrated into the Cylinder Head assembly, the Valve Rotator works in conjunction with the Retainer Valve Kit to facilitate the rotational movement of the valves. This rotation is pivotal in preventing the accumulation of carbon deposits and wear patterns that typically occur on one side of the valve due to the angled approach of the camshaft. The interaction between the Valve Rotator and the Head is symbiotic. As the engine operates, the rotator induces a slight oscillation in the valve’s position, which is instrumental in distributing the thermal and mechanical stresses more evenly across the valve face. This, in turn, promotes a more consistent valve seal against the Cylinder walls, which is essential for maintaining compression and ensuring efficient combustion. Furthermore, the Valve Rotator’s presence within the valve train system contributes to the overall stability and balance of the Cylinder by reducing the likelihood of valve float at higher engine speeds. This is achieved by the rotator’s ability to dampen the harmonics that can lead to valve float, thus allowing for more precise valve timing and improved engine performance 11.

Conclusion

The Cummins 3957914 Valve Rotator is a critical component for maintaining the efficiency and reliability of heavy-duty truck engines. Its role in ensuring even wear distribution across valve faces contributes to enhanced engine performance, longevity, and fuel efficiency. Regular maintenance and proper installation are key to maximizing the benefits of this component.

-

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩ -

Norman, A. (2016). Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc.

↩ -

Atkins, R. D. (2009). An Introduction to Engine Testing and Development. SAE International.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Norman, A. (2016). Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc.

↩ -

Atkins, R. D. (2009). An Introduction to Engine Testing and Development. SAE International.

↩ -

Norman, A. (2016). Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Atkins, R. D. (2009). An Introduction to Engine Testing and Development. SAE International.

↩ -

Norman, A. (2016). Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.