This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

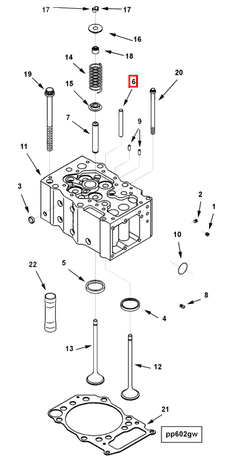

The Valve Crosshead Guide, part number 4006186, is a component manufactured by Cummins, a prominent name in the automotive industry. This guide is integral to the operation of heavy-duty truck engines, ensuring efficient and reliable performance.

Basic Concepts and Functionality

Valve Crosshead Guides are essential to the valve train mechanism within an engine. They facilitate the smooth operation of the valve system by providing a precise path for the valve stems. This ensures that the valves open and close with minimal friction and wear, contributing to the overall efficiency and longevity of the engine 1.

Purpose and Role in Truck Operation

In heavy-duty trucks, the Valve Crosshead Guide maintains the alignment and stability of the valve stems. It interacts closely with other engine components, such as the valve springs and rocker arms, to ensure that the valves operate within their designed parameters. This interaction is vital for the consistent performance of the engine under various operating conditions 2.

Key Features

The Valve Crosshead Guide is designed with several key features that enhance its performance and durability. These include a robust construction material that resists wear and corrosion, precise machining for accurate valve stem guidance, and a design that allows for easy installation and replacement. These characteristics ensure that the guide can withstand the demanding conditions of heavy-duty truck engines 3.

Benefits

The incorporation of the Valve Crosshead Guide into heavy-duty truck engines offers several advantages. It contributes to improved engine efficiency by reducing friction within the valve train. Additionally, it helps in minimizing wear on valve components, leading to extended engine life. The guide also plays a role in enhancing overall engine reliability, ensuring consistent performance over time.

Installation and Compatibility

Proper installation of the Valve Crosshead Guide is crucial for its effective function. It is designed to be compatible with specific engine models, ensuring a precise fit and optimal performance. Before installation, it is important to follow any preparatory steps outlined by the manufacturer to ensure the guide is installed correctly and functions as intended.

Maintenance and Troubleshooting

Routine maintenance of the Valve Crosshead Guide is recommended to ensure its longevity and optimal performance. This includes regular inspections for signs of wear or damage and cleaning to remove any debris that may affect its operation. In case of issues, troubleshooting may involve checking for proper alignment, inspecting for wear on the guide or valve stem, and ensuring that all related components are in good condition.

Performance Impact

The Valve Crosshead Guide influences several engine performance metrics. By ensuring smooth valve operation, it contributes to consistent power output and fuel efficiency. Additionally, proper valve train function can play a role in reducing emissions, as it ensures that the valves open and close at the correct times, optimizing the combustion process.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history and a diverse product portfolio, Cummins is renowned for its commitment to quality and innovation in the automotive industry. The development and production of the Valve Crosshead Guide reflect Cummins’ dedication to providing reliable and high-performance components for heavy-duty applications.

Conclusion

The Valve Crosshead Guide, part number 4006186, is a vital component in the valve train system of heavy-duty truck engines. Its role in ensuring smooth and precise valve operation contributes significantly to engine efficiency, reliability, and longevity. Proper installation, maintenance, and understanding of its function are essential for optimal engine performance.

-

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines. McGraw-Hill, 2008.

↩ -

Hu, Haoran, Simon J Baseley, and Xubin Song. Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International, 2021.

↩ -

Boyce, Meherwan P. Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing, 2002.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.