This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

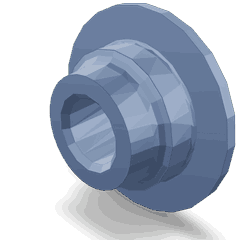

The Valve Spring Retainer 4007183, manufactured by Cummins, is a critical component for heavy-duty truck engines. It secures the valve spring, ensuring proper valve operation under various engine conditions. This part is essential for maintaining the integrity and efficiency of the engine’s valve train system 1.

Basic Concepts of Valve Spring Retainers

A valve spring retainer is a mechanical component that holds the valve spring in position on the valve stem. It ensures the valve spring remains compressed and aligned, allowing the valve to open and close efficiently. This interaction with other components, such as valve springs and valves, ensures smooth and consistent operation of the valve train 2.

Role of the Valve Spring Retainer in Truck Operation

This Cummins part ensures proper valve operation by maintaining consistent valve spring pressure. This is vital for the engine’s efficiency and performance, as it ensures that the valves open and close at the correct times and with the appropriate force. Proper valve operation is fundamental to the engine’s ability to intake air and expel exhaust gases effectively, directly influencing the engine’s overall performance and fuel efficiency 3.

Key Features of the Valve Spring Retainer 4007183

The Valve Spring Retainer 4007183 is characterized by its robust design and material selection. Constructed from high-strength materials, it is engineered to withstand the high stresses and temperatures encountered in heavy-duty truck engines. Unique design elements may include specific geometries that enhance its ability to hold the valve spring securely in place, reducing the risk of spring displacement or failure. These features contribute to the retainer’s performance and durability, ensuring reliable operation under demanding conditions 4.

Benefits of Using the Valve Spring Retainer 4007183

Utilizing this part offers several advantages. It contributes to improved engine reliability by ensuring that the valve springs remain in the correct position, reducing the likelihood of valve train failure. Enhanced performance is another benefit, as the secure positioning of the valve springs allows for more precise valve operation, which can lead to better engine efficiency. Additionally, the durability of the Valve Spring Retainer 4007183 contributes to the longevity of engine components, reducing the need for frequent replacements and maintenance 1.

Troubleshooting Common Issues with Valve Spring Retainers

Identifying and addressing common problems associated with valve spring retainers is important for maintaining engine health. Symptoms of failure may include unusual engine noises, decreased performance, or misfires. Diagnostic procedures involve inspecting the retainer for signs of wear, damage, or displacement. Potential solutions may include cleaning, repair, or replacement of the retainer, depending on the extent of the issue 2.

Maintenance Tips for Valve Spring Retainers

To ensure optimal performance of valve spring retainers, regular maintenance is recommended. This includes inspection procedures to check for wear or damage, cleaning methods to remove any debris or contaminants, and monitoring the condition of the valve springs and other related components. Knowing when to consider replacement is also crucial, as worn or damaged retainers can lead to engine performance issues 3.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes a variety of engines and components designed to meet the demanding requirements of heavy-duty applications, underscoring its commitment to excellence and customer satisfaction 4.

Cummins Valve Spring Retainer 4007183 Compatibility

The Cummins Valve Spring Retainer part number 4007183 is designed to fit seamlessly into various Cummins engine models. This part is crucial for maintaining the integrity and performance of the engine’s valve train system. Here is a detailed look at its compatibility with specific Cummins engines:

QSK78 Engine Series

- QSK78 CM500: This part is specifically engineered to integrate with the QSK78 CM500 engine. The QSK78 series is known for its robust performance and reliability, making it a popular choice in heavy-duty applications. The Valve Spring Retainer 4007183 ensures that the valve springs are securely held in place, preventing any potential failure that could lead to engine damage.

CM500 Engine Group

- CM500: The CM500 engine group includes a range of models that benefit from the precise engineering of the Valve Spring Retainer 4007183. This part is designed to fit perfectly within the CM500’s valve train architecture, ensuring optimal engine operation and longevity. The CM500 engines are widely used in various industries due to their durability and efficiency.

Key Considerations

- Precision Engineering: The Valve Spring Retainer 4007183 is manufactured to exact specifications, ensuring a perfect fit and reliable performance across compatible engines.

- Material Quality: Made from high-quality materials, this part can withstand the rigorous demands of heavy-duty engine operations.

- Compatibility: Designed to fit seamlessly into the specified engine models, this retainer is a critical component for maintaining engine health and performance.

By ensuring that the Valve Spring Retainer 4007183 is correctly installed and maintained, engine operators can expect enhanced reliability and performance from their Cummins engines.

Role of Part 4007183 Valve Spring Retainer in Engine Systems

The part 4007183 Valve Spring Retainer is an essential component in the orchestration of various engine systems, ensuring the seamless operation of the engine’s valve train. It is specifically designed to hold the valve spring in place, maintaining the proper tension on the valve as it opens and closes. This part interfaces with several key components within the engine, contributing to the overall performance and reliability of the engine system 1.

Interaction with the Camshaft

The Valve Spring Retainer works in conjunction with the camshaft, which is responsible for the timing of the valve operation. As the camshaft lobes rise and fall, they open and close the valves. The retainer ensures that the valve spring applies consistent pressure, allowing the valve to follow the camshaft’s profile accurately without any undue wear or damage 2.

Coordination with Connecting Rod and Piston

While the connecting rod and piston are primarily involved in the conversion of linear motion to rotational motion, the efficient operation of the valve train, which the Valve Spring Retainer is a part of, ensures that the air-fuel mixture is admitted into the cylinder at the correct time. This timing is vital for the optimal performance of the connecting rod and piston, as it directly affects the combustion process that drives these components 3.

Integration with Cylinder Head and Cylinder Head Kit

The Valve Spring Retainer is a component that is often included in cylinder head kits or cylinder head rebuild kits. It is installed within the cylinder head, where it plays a role in maintaining the integrity of the valve assembly. The retainer’s function is to keep the valve spring compressed, which is necessary for the valve to seal properly against the cylinder head when closed, preventing any loss of compression 4.

Relationship with Fuel Manifold and Injector

The fuel manifold and injector work in tandem to deliver the precise amount of fuel into the combustion chamber. The Valve Spring Retainer, by ensuring the valve’s proper operation, contributes to the timing of the fuel’s introduction. This synchronization is key to achieving the desired air-fuel ratio, which is critical for engine performance and efficiency 1.

Contribution to Injector Plumbing

Although the injector plumbing is primarily concerned with the delivery of fuel, the operation of the valve train, including the Valve Spring Retainer, affects the engine’s overall performance. A well-functioning valve train ensures that the engine can operate at its designed revolutions per minute (RPM), which in turn affects the demand on the injector plumbing system 2.

Impact on Parts Performance

The performance of engine parts is interdependent. The Valve Spring Retainer, by ensuring the valve spring’s consistent pressure on the valve, contributes to the longevity and performance of other parts. It helps prevent valve float at high RPMs, which can lead to valve-to-piston contact and subsequent damage to both the valve and piston 3.

Conclusion

In summary, the Valve Spring Retainer 4007183 is a component that, while small in size, plays a significant role in the complex symphony of an engine’s operation. Its proper function is integral to the performance and durability of the engine’s valve train and, by extension, the entire engine system 4.

-

Alan Robinson and Andrew Livesey, The Repair of Vehicle Bodies Fifth Edition, Elsevier, 2006.

↩ ↩ ↩ ↩ -

Jon M. Quigley, SAE International’s Dictionary of Testing, Verification and Validation, SAE International, 2023.

↩ ↩ ↩ ↩ -

Ed Sobey, A Field Guide to Automotive Technology, Chicago Review Press, 2009.

↩ ↩ ↩ ↩ -

Robert Huzij, Angelo Spano, Sean Bennett, Modern Diesel Technology Heavy Equipment Systems, Delmar Cengage Learning, 2014.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.