This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4011123 Valve Insert is a component designed for use in commercial truck engines. Its purpose is to enhance the durability and performance of the engine’s valve system. This part plays a role in maintaining the efficiency and reliability of truck engines, contributing to their overall operational effectiveness.

Basic Concepts of Valve Inserts

A valve insert is a component placed within the valve seat of an engine. Its function is to provide a durable and wear-resistant surface for the valve to contact, ensuring a proper seal and efficient operation. Valve inserts interact closely with the engine’s valves and valve seats, playing a role in the engine’s combustion process by facilitating the opening and closing of the valves. Commonly, valve inserts are made from materials like Stellite or other high-strength alloys, chosen for their hardness, wear resistance, and ability to withstand high temperatures and pressures 1.

Purpose of the 4011123 Valve Insert

The 4011123 Valve Insert is designed to enhance the operation of truck engines by providing a robust and durable surface for the valve to seat against. This insert contributes to engine performance by ensuring a reliable seal between the valve and the seat, which is vital for efficient combustion and power delivery. Additionally, it aids in the durability of the engine by reducing wear on the valve seat, thereby extending the engine’s service life 2.

Key Features

The 4011123 Valve Insert features a precision-machined design that ensures a perfect fit within the valve seat. It is composed of high-strength materials that offer excellent wear resistance and durability. Unique to this insert is its specific geometry and surface finish, which are optimized for the demands of commercial truck engines, providing enhanced performance and longevity.

Benefits

Utilizing the 4011123 Valve Insert offers several advantages, including improved engine efficiency through a more reliable valve seal, increased engine longevity due to reduced wear on valve seats, and enhanced reliability of the engine’s valve system. These benefits contribute to overall truck performance by ensuring consistent power delivery and reducing maintenance costs associated with valve system repairs 3.

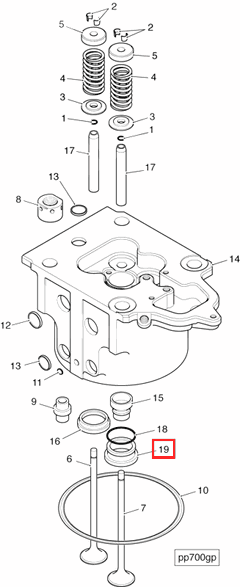

Installation Process

Installing the 4011123 Valve Insert requires careful attention to ensure proper fit and function. The process involves preparing the valve seat to the correct specifications, inserting the valve insert, and then securing it in place using appropriate methods. Special tools may be required to achieve the precise fit necessary for optimal performance.

Troubleshooting and Maintenance

Common issues with valve inserts include wear and improper seating, which can lead to engine performance issues. Troubleshooting these problems involves inspecting the insert for signs of wear or damage and ensuring it is correctly seated. Maintenance tips for the 4011123 Valve Insert include regular inspection during engine service intervals and replacing the insert if significant wear is detected, to maintain engine performance and reliability.

Compatibility and Application

The 4011123 Valve Insert is designed for use in specific engine models and truck applications. It is important to use the correct valve insert for the intended application to ensure compatibility and optimal performance. This insert is commonly used in engines where durability and efficiency are paramount, highlighting the importance of selecting the right component for each application.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its high-quality engine components. The company has a history of innovation and commitment to producing reliable and efficient engine parts, including the 4011123 Valve Insert. Cummins’ reputation is built on its dedication to quality, performance, and customer satisfaction in the commercial vehicle sector.

Valve Insert Fitment for Cummins Part 4011123

The Valve Insert, part number 4011123, manufactured by Cummins, is designed to fit seamlessly within the engine architecture of the QSV81G and QSV91G engines. This part is integral to the engine’s operation, ensuring optimal performance and longevity.

QSV81G and QSV91G Engines

The Valve Insert 4011123 is specifically engineered to integrate with the valve systems of both the QSV81G and QSV91G engines. These engines are part of Cummins’ QSV series, known for their robust design and efficiency. The insert’s precision fitment is crucial for maintaining the integrity of the valve train, which directly impacts the engine’s overall performance and reliability.

The compatibility of the Valve Insert 4011123 with these engines ensures that it meets the stringent requirements of high-performance diesel engines. This part is designed to withstand the extreme conditions within the engine, including high temperatures and pressures, thereby contributing to the engine’s durability and efficiency.

Role of Part 4011123 Valve Insert in Engine Systems

The 4011123 Valve Insert is an integral component in various engine systems, ensuring the efficient operation of the engine’s valve train.

In the Assembly with Inserts Head, the Valve Insert provides a durable surface for the valve seat, enhancing the seal between the valve and the seat. This improves combustion efficiency and reduces the risk of valve seat wear.

When integrated into the Assembly with Valves Head, the Valve Insert supports the valve during operation, minimizing friction and wear. This assembly is essential for maintaining the precise valve timing required for optimal engine performance.

In the Cylinder Assembly Head, the Valve Insert plays a key role in withstanding the high temperatures and pressures generated during combustion. It ensures that the valve seats remain intact and functional over the engine’s lifespan.

The Cylinder Head relies on the Valve Insert to maintain the integrity of the valve seats. Proper seating is vital for effective combustion and emission control, directly impacting the engine’s overall efficiency and performance.

In a Cylinder Head Overhaul Kit, the Valve Insert is often included to replace worn or damaged valve seats. This ensures that the cylinder head can be restored to like-new condition, enhancing engine reliability and performance.

The Head component, whether standalone or part of a larger assembly, benefits from the Valve Insert by providing a robust and heat-resistant surface for the valve seats. This is particularly important in high-performance engines where thermal stress is a significant factor.

The Cylinder and its associated components work in concert with the Valve Insert to ensure that the intake and exhaust valves operate smoothly and efficiently. This coordination is essential for maintaining the engine’s power output and fuel efficiency.

The Mounting Insert may interact with the Valve Insert indirectly by providing a stable platform for the cylinder head. This stability is crucial for maintaining the precise alignment of the valve train components.

Lastly, in an Overhaul Kit, the Valve Insert is a key replacement part that ensures the cylinder head can be refurbished to meet original equipment manufacturer (OEM) specifications. This is vital for restoring the engine to its peak performance after extensive use or damage.

Conclusion

The Cummins 4011123 Valve Insert is a critical component in the maintenance and enhancement of commercial truck engine performance. Its design and materials contribute to the durability, efficiency, and reliability of the engine’s valve system. Proper installation, maintenance, and understanding of its role within the engine system are essential for maximizing the benefits of this Cummins part.

-

Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, Andrew Brown Jr, National Academy of Sciences, 2010

↩ -

Handbook of Diesel Engines, Klaus Mollenhauer and Helmut Tschoeke, Springer, 2010

↩ -

Troubleshooting and Repairing Diesel Engines, 5th Edition, Paul Dempsey, McGraw-Hill, 2018

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.