This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4012492 Valve Insert is a critical component in heavy-duty truck engines, designed to enhance engine efficiency and reliability. Understanding its function and importance is essential for maintaining and optimizing engine performance.

Basic Concepts of Valve Inserts

A valve insert, or valve seat insert, is placed within the cylinder head of an engine to provide a durable, heat-resistant surface for the valve to seal against. This ensures efficient combustion and engine operation by maintaining a proper seal, which is vital for engine performance and longevity 1.

Purpose of the 4012492 Valve Insert

This Cummins part plays a role in the engine’s operation by providing a robust, heat-resistant surface for the valve to seal against. This ensures efficient combustion, contributing to the engine’s efficiency and durability. It also helps in reducing emissions and improving fuel efficiency, which are important factors in heavy-duty truck operations 2.

Key Features

The 4012492 Valve Insert is characterized by its heat-resistant alloy composition, designed to withstand extreme engine conditions. Its precise design ensures a secure and effective seal within the cylinder head, with features like enhanced heat dissipation properties contributing to its performance 3.

Benefits

The Valve Insert offers improved engine performance through efficient combustion, increased durability due to its robust material, and potential cost savings over time due to its longevity and reduced need for frequent replacements. These benefits contribute to the overall efficiency and reliability of heavy-duty trucks.

Installation Process

Proper installation of the 4012492 Valve Insert involves cleaning the installation area, precise alignment of the insert, and careful torquing to the manufacturer’s specifications. Avoiding common pitfalls such as improper alignment and insufficient torquing is crucial for effective sealing and engine performance.

Troubleshooting and Maintenance

Regular maintenance, including inspection for wear and proper torquing during reinstallation, ensures the longevity of the Valve Insert. Identifying when to consider replacement, typically indicated by significant wear or failure to seal properly, is important for maintaining engine efficiency.

Manufacturer Information - Cummins

Cummins is renowned for its commitment to quality and innovation in the automotive components industry. Their products, including the 4012492 Valve Insert, are designed for durability, performance, and compatibility with a wide range of engine types. Cummins’ reputation is built on a history of producing reliable and high-performing components for the automotive and heavy-duty truck industries.

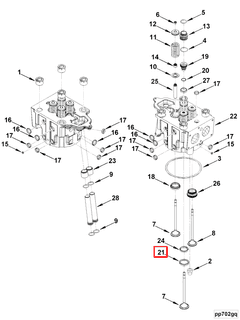

Role of Part 4012492 Valve Insert in Engine Systems

The 4012492 Valve Insert is integral to various engine systems, ensuring optimal performance and longevity. Its primary function is to provide a durable seating surface for the valve within the cylinder head, subjected to high temperatures and pressures.

Interaction with the Cylinder Head

The Valve Insert is press-fitted into the cylinder head, creating a precise seating area for the valve. This ensures a tight seal, preventing combustion gases from leaking into the intake or exhaust ports. The insert’s heat-resistant material enhances the engine’s durability and performance.

Contribution to the Cylinder Head Kit

In a cylinder head kit, the Valve Insert ensures that each valve seats properly, vital for maintaining consistent compression and efficient combustion across all cylinders. Its precise fit and material properties contribute to the overall reliability and performance of the kit.

Relationship with the Camshaft

The Valve Insert indirectly interacts with the camshaft through the valve train. As the camshaft lobes open and close the valves, the insert ensures that the valve faces are properly aligned and sealed. This alignment is essential for maintaining valve timing and efficiency, directly impacting engine performance.

Impact on the Connecting Rod and Piston

While the Valve Insert does not directly contact the connecting rod and piston, its role in ensuring proper valve operation is integral to the engine’s overall efficiency. Efficient valve operation allows for optimal air-fuel mixture intake and exhaust gas expulsion, which directly influences the performance of the connecting rod and piston by ensuring consistent power delivery and reduced stress on these components.

Role in the Cylinder Assembly Head

In the cylinder assembly head, the Valve Insert contributes to the structural integrity and functional efficiency of the assembly. By providing a robust seating area for the valves, it helps maintain the precision required for high-performance engines, particularly in high-rpm applications where valve float and sealing become more challenging.

Significance in Pressure Testing

During a cylinder pressure test, the Valve Insert’s integrity is indirectly assessed. A well-seated valve, thanks to the Valve Insert, will result in consistent pressure readings across all cylinders. Any discrepancies in pressure can often be traced back to issues with valve seating, highlighting the insert’s importance in maintaining engine health.

Overall Engine Performance

The 4012492 Valve Insert, though a small component, significantly influences engine performance by ensuring proper valve seating and sealing. This, in turn, contributes to efficient combustion, consistent power delivery, and overall engine reliability. Engineers and mechanics must pay close attention to the condition and fit of these inserts during engine maintenance and rebuilds to ensure optimal engine operation.

Conclusion

The Cummins 4012492 Valve Insert is a vital component in heavy-duty truck engines, contributing to efficient combustion, engine durability, and overall performance. Proper installation, maintenance, and understanding of its role within the engine system are crucial for optimizing engine operation and longevity.

-

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩ -

Hu, H., Baseley, S. J., & Song, X. (2021). Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International.

↩ -

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.