This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

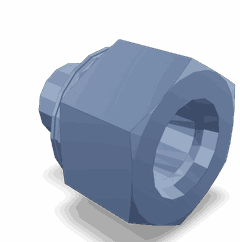

The Cummins 4099168 Check Valve is a component designed for use in commercial truck operations. Its purpose is to regulate the flow of fluids within the truck’s systems, ensuring that fluid moves in the intended direction and preventing backflow. This valve is significant in maintaining the efficiency and reliability of the truck’s fluid systems, contributing to overall performance and longevity.

Basic Concepts of Check Valves

A check valve, also known as a non-return valve, is a mechanical device that allows fluid to flow through it in only one direction. It operates using a mechanism that opens when fluid flows in the correct direction and closes when the flow attempts to reverse. Check valves are commonly used in various fluid systems, including water, gas, and oil, to prevent backflow and maintain system integrity 1.

Purpose of the Cummins 4099168 Check Valve

The Cummins 4099168 Check Valve plays a specific role in the operation of a commercial truck by ensuring that fluid flows in the correct direction within the truck’s fluid systems. This valve is typically installed in systems where backflow could cause damage or reduce efficiency, such as in the fuel or hydraulic systems. By preventing backflow, the valve helps maintain system pressure and ensures that components receive the necessary fluid flow for optimal operation 2.

Key Features

The Cummins 4099168 Check Valve is designed with several key features that enhance its performance. These include a robust construction using high-quality materials to withstand the pressures and temperatures of commercial truck operations. The valve may also feature a spring-loaded mechanism that ensures reliable operation under varying conditions. Additionally, its design may include anti-corrosion coatings to extend its lifespan in harsh environments 3.

Benefits

The Cummins 4099168 Check Valve offers several advantages. It contributes to improved system efficiency by ensuring that fluid flows in the correct direction, reducing the risk of backflow-related issues. The valve’s reliable operation enhances the overall reliability of the truck’s fluid systems, leading to increased uptime and reduced maintenance requirements. Furthermore, its durable construction and anti-corrosion features contribute to the valve’s longevity, making it a cost-effective component for commercial truck operators 4.

Installation Considerations

When installing the Cummins 4099168 Check Valve, it is important to follow guidelines and best practices to ensure proper function. This may include preparing the installation site by cleaning and inspecting the piping to ensure there are no obstructions. Using the correct tools and following the manufacturer’s instructions for torque settings and alignment will help ensure a secure and effective installation. It is also important to verify the valve’s orientation to ensure it allows fluid to flow in the correct direction.

Troubleshooting Common Issues

Common problems associated with check valves can include leakage, failure to open or close properly, and corrosion. Diagnosing these issues may involve inspecting the valve for physical damage, checking for proper installation, and ensuring that the valve’s mechanism is functioning correctly. Potential solutions may include cleaning the valve, replacing worn components, or, in some cases, replacing the valve entirely.

Maintenance Tips

To ensure optimal performance and longevity of the Cummins 4099168 Check Valve, regular maintenance is recommended. This includes periodic inspection for signs of wear or damage, cleaning the valve to remove any buildup that could affect its operation, and verifying that it is properly seated and aligned. Following these maintenance procedures will help ensure the valve continues to function effectively, contributing to the overall efficiency and reliability of the truck’s fluid systems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long history of innovation and excellence in the commercial truck industry. The company is known for its commitment to quality, reliability, and performance, making it a trusted name among commercial truck operators worldwide.

Cummins Engine Check Valve 4099168

The Cummins Check Valve 4099168 is a critical component designed to ensure the proper flow of fluids within the engine systems of the QSK19 CM850 MCRS and QSK60 CM850 MCRS engines. This check valve is engineered to prevent backflow, which can cause significant damage to the engine’s components and affect its overall performance.

In the QSK19 CM850 MCRS engine, the check valve is strategically placed to maintain the integrity of the lubrication system. It ensures that oil flows in the correct direction, preventing any reverse flow that could lead to contamination or inadequate lubrication of critical parts. This is particularly important in maintaining the engine’s longevity and efficiency.

Similarly, in the QSK60 CM850 MCRS engine, the check valve plays a pivotal role in the cooling system. It ensures that coolant flows consistently through the engine, preventing any reverse flow that could cause overheating or inefficient cooling. This helps in maintaining the engine’s optimal operating temperature, thereby enhancing its performance and reliability.

Both engines benefit from the precise engineering of the Cummins Check Valve 4099168, which is designed to withstand the high pressures and temperatures typical of these robust engines. The check valve’s design ensures that it can handle the demanding conditions of these engines, providing reliable performance over extended periods.

Role of Part 4099168 Check Valve in Engine Systems

The Part 4099168 Check Valve is an integral component in the orchestration of various engine systems, ensuring the seamless operation of the engine and its monitoring mechanisms.

In the Engine System, the Check Valve facilitates the unidirectional flow of fluids, which is essential for maintaining pressure and preventing backflow. This ensures that the engine receives a consistent supply of fuel or lubricants, optimizing performance and efficiency.

Within the Engine Monitoring System, the Check Valve plays a significant role by ensuring accurate readings and reliable data transmission. It helps in maintaining the integrity of the fluid lines that carry essential data to the monitoring instruments, thus ensuring that the readings are not compromised by reverse flow.

In the context of the Instrument System, the Check Valve aids in the precise measurement and display of various engine parameters. By preventing reverse flow, it ensures that the instruments receive a steady and uncontaminated flow of the medium being measured, leading to accurate and reliable readings.

Overall, the Part 4099168 Check Valve is a silent yet significant contributor to the harmonious functioning of engine, engine monitoring, and instrument systems, ensuring that each component operates within its designed parameters.

Conclusion

The Cummins 4099168 Check Valve is a vital component in the fluid systems of commercial trucks, ensuring the proper flow of fluids and preventing backflow. Its robust construction, reliable operation, and anti-corrosion features make it a durable and cost-effective solution for maintaining the efficiency and reliability of truck fluid systems. Regular maintenance and proper installation are key to ensuring the valve’s optimal performance and longevity.

-

Sully, F. K. (1998). Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing.

↩ -

Awari, G.K., Kumbhar, V.S., & Tirpude, R.B. (2011). Automotive Systems Principles and Practice. CRC Press.

↩ -

Goodnight, N., & Van Gelder, K. (2018). Automotive Braking Systems. Jones & Bartlett Learning.

↩ -

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.