This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4313304 Pressure Relief Valve is designed to manage and regulate pressure within heavy-duty truck systems, ensuring pressure levels remain within safe operating limits and protecting the system from potential damage due to excessive pressure 1. This valve is integral to maintaining the integrity and efficiency of the truck’s systems.

Basic Concepts of Pressure Relief Valves

Pressure relief valves automatically release pressure from a system when it exceeds a predetermined limit. They open a valve when the pressure reaches a certain threshold, allowing excess pressure to escape and preventing system overpressure. These valves are crucial in hydraulic, pneumatic, and fuel systems where pressure management is essential for safety and performance 2.

Role of the 4313304 Pressure Relief Valve in Truck Operation

The 4313304 Pressure Relief Valve regulates pressure in heavy-duty trucks, typically installed in systems where pressure build-up could lead to component failure or safety hazards. Its failure could result in system overpressure, causing potential damage to components and reduced system efficiency 3.

Key Features of the 4313304 Pressure Relief Valve

The 4313304 Pressure Relief Valve features a robust design engineered to withstand heavy-duty truck operations. Constructed from high-quality materials, it ensures durability and reliability. The valve allows for setting adjustments, enabling it to be tailored to specific system requirements. Its unique attributes enhance performance and reliability in various operating conditions.

Benefits of Using the 4313304 Pressure Relief Valve

The 4313304 Pressure Relief Valve offers improved system safety through effective pressure management, enhanced performance by maintaining optimal pressure levels, and longevity of associated components due to reduced stress from pressure fluctuations.

Troubleshooting the 4313304 Pressure Relief Valve

Common issues with the valve include malfunctions due to wear, contamination, or incorrect settings. Symptoms to watch for include unusual noise, system overpressure, or inconsistent system performance. Initial steps for diagnosis and resolution involve inspecting the valve for wear or damage, cleaning the valve and its surroundings, and verifying the settings against system requirements.

Maintenance Practices for the 4313304 Pressure Relief Valve

Recommended maintenance routines include regular inspection intervals to check for wear or damage, cleaning procedures to remove contaminants, and considering replacement when the valve shows signs of significant wear or fails to operate within specified parameters.

Integration with Other Systems

The 4313304 Pressure Relief Valve interacts with other components and systems within the truck, emphasizing the importance of system-wide consideration in maintenance and troubleshooting. Its proper function is dependent on the correct operation of associated components, and any issues within the system can affect the performance of the valve.

Historical Development and Technological Advancements

The evolution of pressure relief valve technology has led to significant improvements in design, materials, and functionality. The 4313304 model represents current advancements in the field, incorporating modern engineering principles to enhance performance, reliability, and ease of maintenance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins offers a wide range of products for various industries, including heavy-duty trucks. The company’s standing in the industry is a testament to its commitment to quality and technological advancement, providing context for the development and quality of the 4313304 Pressure Relief Valve.

Cummins Pressure Relief Valve Part 4313304 Compatibility

The Cummins Pressure Relief Valve part number 4313304 is engineered to ensure the safe and efficient operation of certain engine models. This part manages and regulates the pressure within the engine’s hydraulic or fuel systems, preventing potential damage from over-pressurization.

Engine Compatibility

The Pressure Relief Valve part 4313304 is specifically designed to fit the following Cummins engine models:

- QSK95 CM2350 K111

- QSK95 CM2350 K113

These engines are part of the Cummins QSK95 series, known for robust performance and reliability in various industrial and power generation applications. The Pressure Relief Valve ensures these engines maintain optimal pressure levels, enhancing their longevity and operational efficiency.

Installation and Functionality

When installed in the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines, the Pressure Relief Valve part 4313304 monitors system pressure and diverts excess pressure to prevent damage. This is achieved through a precisely calibrated spring mechanism that opens a valve to release excess pressure when it exceeds a predetermined threshold.

Importance of Proper Installation

Proper installation of the Pressure Relief Valve is crucial for the engine’s performance and safety. Technicians should follow the manufacturer’s guidelines to ensure the valve is correctly positioned and securely fastened. Regular maintenance checks should also be performed to verify that the valve is functioning as intended, which includes inspecting for any signs of wear, corrosion, or blockage.

Maintenance Considerations

To maintain the effectiveness of the Pressure Relief Valve, it is essential to adhere to the recommended maintenance schedule. This includes periodic inspections and, if necessary, replacement of the valve to ensure it continues to provide the necessary pressure regulation. Using genuine Cummins parts, such as the Pressure Relief Valve part 4313304, ensures compatibility and reliability, minimizing the risk of system failures.

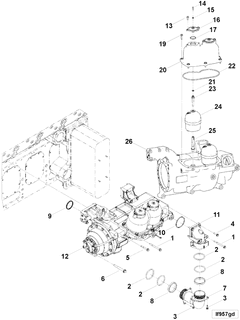

Role of Part 4313304 Pressure Relief Valve in Engine Systems

The part 4313304 Pressure Relief Valve is integral to maintaining the integrity and efficiency of engine systems, particularly in relation to the lubricating oil circuit. This valve is strategically integrated into the system to manage and regulate the pressure within the lubricating oil pathways, ensuring optimal performance and protection of engine components.

When the lubricating oil is circulated through the engine, it passes through the lubricating oil filter. The filter is responsible for removing contaminants and particles that could otherwise cause wear and damage to engine parts. The lubricating oil filter head plays a key role in this process by securely housing the filter and facilitating the flow of oil into and out of the filter element.

In scenarios where the pressure within the lubricating oil system exceeds safe limits, the part 4313304 Pressure Relief Valve activates. This action prevents excessive pressure from building up, which could lead to damage to the lubricating oil filter or other components within the system. By relieving the pressure, the valve ensures that the lubricating oil continues to flow smoothly and effectively, maintaining the necessary lubrication for all moving parts within the engine.

The lubricating oil filter kit, which typically includes the filter, filter head, and associated gaskets and seals, works in conjunction with the Pressure Relief Valve to provide a comprehensive solution for maintaining clean and pressurized lubricating oil. The kit ensures that all components are compatible and function together seamlessly, contributing to the overall reliability and performance of the engine.

Conclusion

The part 4313304 Pressure Relief Valve is a vital component in the lubricating oil system, working alongside the filter, filter head, and filter kit to ensure that the engine receives clean, pressurized oil, thereby enhancing its longevity and operational efficiency.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.