This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

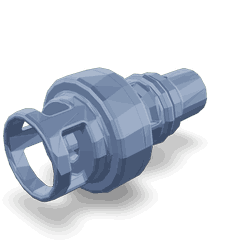

The Cummins Part #4325286 Check Valve is a specialized component designed for use in commercial truck systems. Its purpose is to regulate the flow of fluids, ensuring that they move in a single direction within the system. This part plays a role in maintaining the efficiency and reliability of truck operations by preventing backflow, which can lead to system inefficiencies and potential damage 1.

Basic Concepts of Check Valves

A check valve, also known as a non-return valve, is a mechanical device that allows fluid to flow through it in only one direction. It operates using a mechanism that opens when fluid flows in the correct direction and closes when the flow attempts to reverse. Check valves are commonly used in various fluid systems, including water, gas, and oil, to prevent backflow and maintain system integrity 2.

Purpose of the 4325286 Check Valve in Truck Operations

This Cummins part is specifically designed to function within the fuel, lubrication, or hydraulic systems of commercial trucks. In the fuel system, it ensures that fuel flows in the correct direction, preventing backflow that could disrupt engine performance. In lubrication systems, it helps maintain consistent oil flow to critical components, ensuring they remain properly lubricated. For hydraulic systems, the check valve plays a role in maintaining pressure and preventing fluid reversal, which is vital for the operation of hydraulic actuators and other components.

Key Features

The 4325286 Check Valve is characterized by its robust design and the use of high-quality materials. It features a durable housing that resists corrosion and wear, ensuring longevity in demanding truck environments. The valve’s internal components are precision-engineered to provide reliable operation under various conditions. Additionally, it may include unique attributes such as a spring-loaded mechanism for quick response to flow changes or a seal design that enhances fluid tightness.

Benefits of Using the 4325286 Check Valve

Incorporating this part into truck systems offers several advantages. It contributes to improved system efficiency by ensuring unidirectional fluid flow, which can lead to better overall performance. The valve’s reliable operation enhances the reliability of the truck’s systems, reducing the likelihood of unexpected failures. Additionally, its durable construction and efficient design can result in maintenance savings over time by minimizing the need for frequent replacements or repairs.

Installation and Integration

Proper installation of the 4325286 Check Valve is crucial for its effective operation. It should be installed in the correct orientation to ensure that fluid flows in the intended direction. Integration into existing truck systems may require attention to compatibility with other components and adherence to manufacturer guidelines. Ensuring that the valve is securely mounted and that all connections are tight will help prevent leaks and ensure optimal performance.

Troubleshooting and Maintenance

Common issues with the 4325286 Check Valve may include blockages, leaks, or failure to open or close properly. Diagnostic procedures should begin with a visual inspection for obvious signs of damage or wear. Testing the valve’s operation under system pressure can help identify issues with its functionality. Regular maintenance, such as cleaning and inspecting for wear, can help ensure the valve’s longevity and optimal performance. Replacement parts or the valve itself may be necessary if significant wear or damage is detected.

Performance in Various Conditions

The 4325286 Check Valve is designed to perform reliably under a range of operating conditions. It can withstand extreme temperatures, high pressure, and corrosive environments, making it suitable for use in various truck applications. Its robust construction and high-quality materials contribute to its ability to maintain performance in challenging conditions.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories through a network of more than 600 company-owned and independent distributor facilities and more than 7,200 dealer locations. The company’s product range includes engines for on-highway, off-highway, and stationary applications, as well as filtration and aftermarket parts. Cummins is dedicated to advancing technology and providing reliable, efficient power solutions to meet the needs of its customers.

Cummins Check Valve 4325286 in Engine Applications

The Cummins Check Valve 4325286 is a critical component in various engine systems, ensuring the unidirectional flow of fluids. This valve is designed to prevent backflow, which can be detrimental to engine performance and longevity. Here, we explore its integration into specific engine models and groups.

ISV (Nissan) Engines

In the ISV (Nissan) engines, the Cummins Check Valve 4325286 plays a pivotal role in maintaining the integrity of the fuel and coolant systems. Its placement within the engine architecture is meticulously designed to handle the high pressures and temperatures typical of these engines. The valve’s robust construction ensures it can withstand the demanding conditions, providing reliable operation over extended periods.

Cummins Engine Groups

The Cummins Check Valve 4325286 is also integral to various Cummins engine groups, where it is used to manage fluid flow in the following ways:

- Fuel Systems: In Cummins engines, the check valve is often positioned in the fuel lines to prevent reverse flow, which can lead to contamination and engine damage.

- Coolant Systems: Within the coolant pathways, the valve ensures that coolant flows in the correct direction, maintaining optimal engine temperature and preventing overheating.

- Oil Systems: The check valve can also be found in the oil systems, where it helps maintain consistent oil pressure and prevents oil from flowing back into the sump, which could lead to engine lubrication issues.

The integration of the Cummins Check Valve 4325286 in these engines underscores its importance in ensuring smooth and efficient engine operation. Its design and placement are critical to the overall performance and reliability of the engines it serves.

Role of Part 4325286 Check Valve in Engine Systems

The Part 4325286 Check Valve is an essential component in maintaining the efficiency and reliability of various engine systems. Its primary function is to allow fluid or gas to flow in one direction while preventing backflow, which is vital for the proper operation of several engine components.

Crankcase Breather

In the crankcase breather system, the check valve ensures that gases expelled from the crankcase are released efficiently without allowing external contaminants to enter. This helps in maintaining the cleanliness of the crankcase and prolonging the life of the engine by preventing the buildup of harmful deposits.

Cylinder Block

When integrated with the cylinder block, the check valve plays a role in managing the flow of lubricants and coolants. It ensures that these fluids are directed correctly to their intended paths, enhancing the cooling and lubrication processes which are essential for the cylinder block’s durability and performance.

Cylinder Block Stiffener

The cylinder block stiffener benefits from the check valve by ensuring that any fluids used for cooling or lubrication are consistently supplied without interruption. This consistent flow helps in maintaining the structural integrity of the stiffener, reducing the risk of thermal expansion and contraction issues.

Long Block Kit

In a long block kit, the check valve is often used to regulate the flow of fluids within the engine assembly. It ensures that oil and coolant are distributed effectively throughout the engine, which is crucial for the long block’s overall performance and longevity.

Multiple Function Lubrication Housing

The multiple function lubrication housing relies on the check valve to maintain the proper pressure and flow of lubricants. This ensures that all moving parts within the housing receive adequate lubrication, reducing friction and wear, and enhancing the efficiency of the lubrication system.

Conclusion

The Cummins Part #4325286 Check Valve is a vital component in the maintenance and operation of commercial truck and engine systems. Its role in preventing backflow and ensuring unidirectional fluid flow contributes significantly to the efficiency, reliability, and longevity of these systems. Proper installation, regular maintenance, and understanding its integration into various engine components are essential for maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.