This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

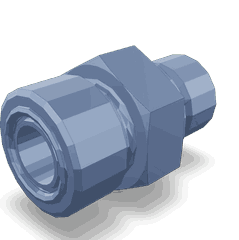

The Cummins 4332364 Check Valve is designed for use in commercial truck operations. It regulates fluid flow within the truck’s systems, ensuring that fluid moves in the intended direction and preventing backflow. This valve is crucial for maintaining the efficiency and reliability of truck operations, particularly in the fuel and lubrication systems.

Basic Concepts of Check Valves

A check valve, or non-return valve, allows fluid to flow through it in one direction only and automatically closes to prevent reverse flow. These valves are used in fluid systems to maintain pressure, prevent contamination, and protect equipment from damage due to backflow. They operate using a simple mechanism where a disc or ball moves to block the flow when pressure reverses 1.

Purpose of the 4332364 Check Valve in Truck Operations

This Cummins part ensures the proper flow of fluids within the fuel and lubrication systems. In the fuel system, it maintains consistent fuel pressure and prevents fuel from flowing back into the tank, which could cause engine issues. In the lubrication system, it ensures that oil flows to critical components without backflow, which is vital for maintaining engine health and performance 2.

Key Features of the 4332364 Check Valve

The design and construction of this part include several features that enhance its performance and durability. It is made from high-quality materials that resist corrosion and wear, ensuring long-term reliability. The valve’s build quality is robust, capable of withstanding high pressures and temperatures commonly encountered in truck operations. Unique attributes may include a precision-machined seat and a durable disc or ball mechanism that ensures a tight seal against backflow.

Benefits of Using the 4332364 Check Valve

Using this part provides several advantages. It contributes to improved system efficiency by ensuring that fluids flow in the correct direction, reducing the risk of contamination and system failures. The valve’s reliable operation enhances the overall reliability of the truck’s systems. Additionally, its durable construction promotes longevity, reducing the need for frequent replacements and maintenance 3.

Installation and Integration

Proper installation of this part is crucial for its effective operation. It should be installed in the correct orientation to ensure that it functions as intended. Integration into truck systems requires attention to the valve’s compatibility with existing components and the system’s pressure and temperature ratings. Following manufacturer guidelines for installation ensures optimal performance and longevity.

Troubleshooting Common Issues

Common problems associated with check valves include leakage, failure to open or close properly, and blockages. Troubleshooting these issues involves checking for proper installation, inspecting for damage or wear, and ensuring that the valve is compatible with the system’s operating conditions. Step-by-step methods to address these issues may include cleaning the valve, replacing worn components, or adjusting the system to better suit the valve’s requirements.

Maintenance Tips

Regular maintenance practices are recommended to ensure the longevity and optimal performance of this part. This includes periodic inspection for signs of wear or damage, cleaning to remove any buildup that could impede function, and testing the valve’s operation to ensure it opens and closes as intended. Adhering to a maintenance schedule helps prevent unexpected failures and extends the valve’s service life.

Performance Under Various Conditions

This part is designed to perform under a range of operating conditions, including extreme temperatures and high-pressure environments. Its materials and construction are chosen to withstand these conditions, ensuring reliable operation regardless of the external factors. Analysis of its performance under various conditions confirms its suitability for use in demanding commercial truck applications.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. Its product range includes engines, powertrain components, and aftermarket parts, all designed to meet the rigorous demands of commercial transportation.

Cummins Check Valve 4332364 Compatibility with QSK95 Engines

The Cummins Check Valve 4332364 is designed to integrate seamlessly with the QSK95 series engines, specifically the QSK95 CM2350 K111 and QSK95 CM2350 K113 models. This check valve ensures the proper flow of fluids within the engine’s system, preventing backflow and maintaining system efficiency.

QSK95 CM2350 K111 and QSK95 CM2350 K113

Both the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines benefit from the installation of the Cummins Check Valve 4332364. This part is engineered to fit precisely within the engine’s architecture, ensuring optimal performance and reliability. The check valve’s design allows it to handle the specific pressures and flow rates encountered in these engines, contributing to the overall durability and efficiency of the QSK95 series.

The integration of the Cummins Check Valve 4332364 into these engines is straightforward, thanks to its compatibility with the engine’s design. This ensures that the valve can be installed with minimal disruption to the engine’s operation, providing a reliable solution for maintaining fluid flow integrity.

Role of Part 4332364 Check Valve in Engine Systems

The part 4332364 check valve is a component in maintaining the efficiency and reliability of engine systems, particularly in the context of plumbing and fuel drain systems.

In the plumbing system of an engine, the check valve ensures that the flow of fluids is unidirectional. This is particularly important in systems where backflow could lead to contamination or damage. By allowing fluid to flow in one direction only, the check valve helps maintain the integrity of the system, ensuring that clean fluids are delivered to critical components without the risk of contamination from downstream sources.

In the fuel drain system, the check valve plays a similarly important role. It prevents fuel from flowing back into the system once it has been drained. This is vital for maintaining the purity of the fuel supply and ensuring that the engine operates efficiently. By blocking reverse flow, the check valve helps to prevent fuel contamination, which can lead to engine performance issues or even failure.

Overall, the integration of the part 4332364 check valve into these systems enhances their functionality and reliability, ensuring that the engine operates smoothly and efficiently.

Conclusion

The Cummins 4332364 Check Valve is a vital component in commercial truck operations, ensuring the proper flow of fluids within the fuel and lubrication systems. Its design, featuring high-quality materials and robust construction, ensures long-term reliability and performance under various operating conditions. Proper installation, regular maintenance, and troubleshooting common issues are essential for maximizing the valve’s efficiency and longevity. The integration of this part into QSK95 engines further demonstrates its compatibility and effectiveness in demanding applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.