This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

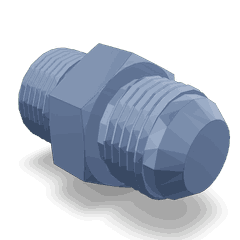

The Cummins 4348998 Check Valve is a component designed for use in commercial truck systems. Its purpose is to regulate the flow of fluids, ensuring that they move in a single direction within the system. This valve plays a role in maintaining the efficiency and reliability of truck operations by preventing backflow, which can lead to system inefficiencies or damage 2.

Basic Concepts of Check Valves

A check valve, also known as a non-return valve, is a mechanical device that allows fluid to flow through it in only one direction. It operates using a mechanism that opens under the pressure of the fluid flow and closes when the flow stops or reverses, thereby preventing backflow. Check valves are commonly used in various fluid systems, including water, gas, and hydraulic systems, to ensure that the fluid moves in the intended direction 1.

Purpose of the Cummins 4348998 Check Valve

The Cummins 4348998 Check Valve is specifically designed to function within the fuel or hydraulic systems of commercial trucks. It ensures that the fluid, whether it be fuel or hydraulic fluid, flows in the correct direction, which is vital for the proper operation of the truck’s engine and hydraulic systems. By preventing backflow, this valve helps maintain system pressure and efficiency, contributing to the overall performance of the truck 2.

Key Features

The Cummins 4348998 Check Valve is constructed from durable materials that are resistant to corrosion and wear, ensuring longevity in demanding commercial truck environments. Its design includes a spring-loaded mechanism that opens and closes in response to fluid pressure, providing reliable operation. Unique attributes of this valve may include a compact size for easy installation in tight spaces and a design that minimizes pressure drop across the valve, enhancing system efficiency 2.

Benefits

The advantages of using the Cummins 4348998 Check Valve include improved system efficiency through the prevention of backflow, which can lead to energy losses. Its reliable operation contributes to the overall reliability of the truck’s systems. Additionally, by ensuring proper fluid flow, this valve can help reduce maintenance costs associated with system inefficiencies or damage caused by backflow 2.

Installation Considerations

When installing the Cummins 4348998 Check Valve, it is important to follow guidelines for proper orientation, ensuring that the valve is installed in the correct direction of fluid flow. The installation may require specific tools, and it is crucial to integrate the valve within the existing system according to manufacturer recommendations to ensure optimal performance and compatibility 2.

Troubleshooting and Maintenance

Common issues with the Cummins 4348998 Check Valve may include failure to open or close properly, which can be diagnosed through inspection and testing. Regular maintenance routines, such as cleaning and inspecting the valve for wear or damage, can help ensure its longevity and optimal performance. Following manufacturer guidelines for maintenance can prevent many issues from arising 2.

Performance in Various Conditions

The Cummins 4348998 Check Valve is designed to perform under a range of operating conditions, including extreme temperatures and high-pressure environments. Its robust construction and reliable operation make it suitable for use in the demanding conditions often encountered in commercial truck applications 2.

Compatibility and Integration

The Cummins 4348998 Check Valve is compatible with various truck models and systems, designed for seamless integration into different setups. Tips for ensuring compatibility and smooth integration include consulting the manufacturer’s specifications and guidelines for installation and operation within specific truck models and systems 2.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves commercial truck, bus, construction, agricultural, and industrial markets. The company’s reputation in the commercial truck industry is built on its commitment to providing reliable, efficient, and durable products that meet the needs of its customers 2.

Role of 4348998 Check Valve in Engine Systems

The 4348998 Check Valve is an essential component in the fluid dynamics of engine systems, particularly within the module and engine control setups.

In the module, the Check Valve ensures unidirectional flow of fluids, which is vital for maintaining the integrity of the system’s pressure and flow rates. It prevents backflow, which could otherwise lead to inefficiencies or damage to other components within the module. This unidirectional flow capability is particularly important in systems where precise fluid management is required to ensure optimal performance and longevity of the module.

Within the engine control system, the Check Valve plays a significant role in regulating the flow of fluids to various engine components. It helps in maintaining consistent pressure levels, which is essential for the accurate functioning of sensors and actuators that are part of the engine control unit (ECU). By ensuring that fluid only flows in the intended direction, the Check Valve aids in the stable operation of the engine control system, contributing to overall engine efficiency and reliability.

Moreover, the Check Valve’s ability to prevent backflow is beneficial in scenarios where the engine control system needs to quickly respond to changes in operating conditions. This rapid response is crucial for maintaining engine performance under varying loads and speeds, ensuring that the engine operates within its designed parameters.

Conclusion

In summary, the Cummins 4348998 Check Valve is integral to the fluid management within both the module and engine control systems, enhancing the efficiency, reliability, and performance of the engine as a whole. Its role in preventing backflow and ensuring unidirectional fluid flow is crucial for the proper operation and longevity of commercial truck systems.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.