4362007

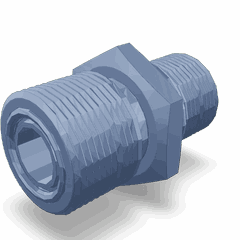

Check Valve

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4362007 Check Valve is a component designed for use in commercial trucks. Its purpose is to regulate the flow of fluids within the truck’s systems, ensuring that fluid moves in the intended direction and preventing backflow. This valve plays a role in maintaining the efficiency and reliability of the truck’s fluid systems.

Basic Concepts of Check Valves

A check valve, also known as a non-return valve, is a mechanical device that allows fluid to flow through it in only one direction. It operates by using a movable element, such as a flap or a ball, that opens when fluid flows in the correct direction and closes when the flow attempts to reverse. Check valves are commonly used in fluid systems to prevent backflow, which can cause damage or inefficiency in the system 1.

Purpose of the Cummins 4362007 Check Valve

The Cummins 4362007 Check Valve is specifically designed to function within the fluid systems of commercial trucks. It ensures that fluid, such as coolant or lubricant, flows in the correct direction, which is vital for the proper operation of the truck’s engine and other components. By preventing backflow, this valve helps maintain system pressure and efficiency 2.

Key Features

The Cummins 4362007 Check Valve is characterized by several key features that enhance its performance. It is constructed from durable materials to withstand the harsh conditions within a truck’s engine compartment. The valve’s design includes a precision-machined seat and a resilient sealing element, which together ensure a tight seal and reliable operation. Additionally, the valve is engineered to operate efficiently under a range of temperatures and pressures typical in commercial truck applications.

Benefits

The Cummins 4362007 Check Valve offers several advantages. It contributes to improved system efficiency by ensuring that fluid flows in the correct direction, which can lead to better engine performance and fuel efficiency. The valve’s reliable operation enhances the overall reliability of the truck’s fluid systems. Furthermore, its durable construction and precise engineering contribute to the valve’s longevity, reducing the need for frequent replacements 3.

Installation and Integration

Proper installation of the Cummins 4362007 Check Valve is important for its effective operation. It should be installed in the correct orientation, with the flow arrow indicating the direction of fluid flow. Before installation, the system should be clean and free of debris to prevent contamination. Following the manufacturer’s guidelines for torque specifications and sealing procedures will help ensure a secure and leak-free installation.

Troubleshooting and Maintenance

Regular maintenance of the Cummins 4362007 Check Valve is important to ensure its continued reliable operation. Inspections should be conducted to check for signs of wear or damage, such as corrosion or debris buildup. If the valve is not operating correctly, it may be necessary to clean or replace the sealing element. Keeping the valve and its surrounding system clean and free of contaminants will help prolong its service life.

Common Applications

The Cummins 4362007 Check Valve is commonly used in various truck systems, including engine cooling, lubrication, and hydraulic systems. Its application is not limited to Cummins engines but can be found in a wide range of commercial truck configurations where reliable fluid flow control is required.

Safety Considerations

When working with the Cummins 4362007 Check Valve, it is important to follow safety guidelines. This includes wearing appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential hazards. Additionally, ensuring that the system is depressurized before beginning any work on the valve will help prevent accidents.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and commitment to quality, Cummins has established itself as a trusted name in the commercial truck industry. The company’s products are known for their reliability, efficiency, and durability, making them a popular choice for commercial vehicle applications.

Compatibility with Various Engine Models

The Cummins Check Valve 4362007 is designed to be compatible with a range of Cummins engine models. Here is a detailed overview of its compatibility across different engine series:

QSK19 and QSK60 Series

The Check Valve 4362007 fits seamlessly with the QSK19 CM850 MCRS and QSK60 CM850 MCRS engines. These engines are known for their robust design and efficient performance, making the check valve an essential component in maintaining system integrity.

QSK38 and QSK50 Series

For the QSK38 CM850 MCRS and QSK50 CM2150 MCRS engines, the check valve 4362007 ensures proper fluid flow direction, preventing backflow and maintaining system pressure. This is particularly important in these engines, which are designed for heavy-duty applications.

High-Output QSK50 Series

The QSK50 CM2350 K108 engine, a high-output variant, also benefits from the use of the Check Valve 4362007. This engine is engineered for maximum power and efficiency, and the check valve plays a role in ensuring that the system operates smoothly.

QSK95 Series

Lastly, the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines are compatible with the Check Valve 4362007. These engines are designed for extreme durability and performance, and the check valve is a key component in maintaining the high standards of these models.

By ensuring compatibility with these various engine models, the Cummins Check Valve 4362007 provides a reliable solution for maintaining system efficiency and preventing potential issues related to fluid flow.

Role of Part 4362007 Check Valve in Engine Systems

Integration with Plumbing Systems

In plumbing systems associated with engine operations, the 4362007 Check Valve is instrumental in maintaining the unidirectional flow of fluids. This ensures that the coolant, oil, or other fluids do not reflux, which could lead to inefficiencies or damage to the engine components. The valve is typically installed in the return lines to prevent backflow, thus preserving the integrity of the pressure differentials necessary for optimal engine performance.

Function within Fuel Drain Systems

When incorporated into fuel drain systems, the 4362007 Check Valve plays a significant role in ensuring that fuel, once drained from the system, does not inadvertently flow back into the engine’s fuel lines. This is particularly important in scenarios where the engine is shut down and fuel needs to be safely expelled from the system to prevent contamination or unsafe conditions. The valve’s design allows it to automatically close when the pressure differential reverses, effectively sealing the fuel lines and preventing any reverse flow.

This component is essential for maintaining the purity of the fuel supply and ensuring that the engine operates on clean, uncontaminated fuel, which is vital for combustion efficiency and engine longevity.

Conclusion

The Cummins 4362007 Check Valve is a critical component in the fluid systems of commercial trucks, ensuring efficient and reliable operation. Its durable construction, precise engineering, and compatibility with various Cummins engine models make it a valuable asset for maintaining system integrity and performance. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩ -

Bari, S. (2013). Diesel Engine Combustion, Emissions and Condition Monitoring. InTech.

↩ -

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.